產(chǎn)品中心

Perkins珀金斯900 3.152柴油發(fā)動機3142 A081排氣閥/ZZ80235汽缸蓋總成

詳細描述

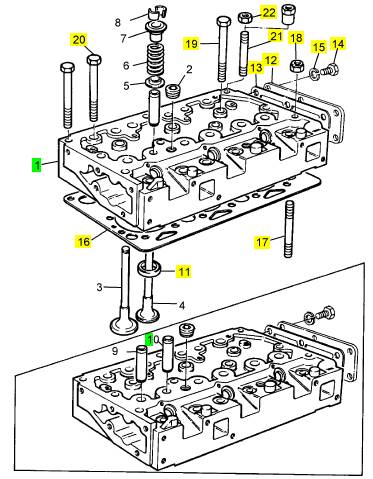

項目 零配件號碼 最新件號 描述

3142 A081 3 3142 A081 排氣閥

1 ZZ80235 1 ZZ80235 汽缸蓋總成

(1) ZZ80235P 1 ZZ80235R 汽缸蓋總成 -EXCH

11 33124428 3 33124428 閥座氣門座圈

12 1 蓋

13 1 接合

14 6 螺旋

15 6 墊圈

16 3681 E024 1 3681 E024 汽缸蓋墊片

17 32524132 1 32524132 圖釘

18 33221329 1 33221329 螺帽

19 32181457 5 32181457 汽缸蓋螺拴

20 32181458 9 32181458 汽缸蓋螺拴

21 32524148 3 32524148 圖釘

22 33221329 3 33221329 螺帽

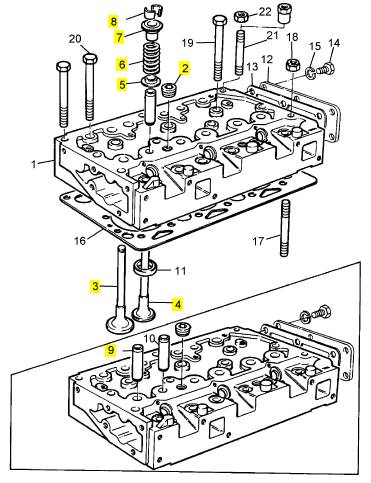

項目 零配件號碼 最新件號 描述

ZZ80017 1 檢查歷史 汽缸蓋總成

2 2431154 2 2431154 栓塞

2 2431154 2 2431154 栓塞

3 31431681 3 31431681 進氣閥

4 31431031 3 31431031 排氣閥

5 33415133 6 33415133 彈簧塾圈

6 0780012 6 0780012 閥彈簧

7 33423148 6 33423148 帽

8 0230001 12 0230001 閥筒夾

8 0230001 6 0230001 閥筒夾

9 U3316A031 3 3316 A031 氣門導(dǎo)管

10 U3313E734 3 3313 E734 氣門導(dǎo)管

|

Disassembly and Assembly Section |

|

g01383260 |

|

g01383261 |

|

Illustration 42 |

|

Illustration 44 |

|

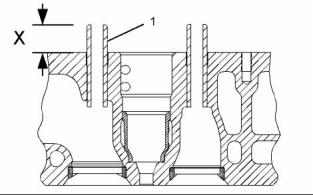

1. Use Tooling (A) and a hammer in order to remove the valve guides from the cylinder head. |

|

2. Use Tooling (A) and Tooling (B) to install valve guides (1) in the cylinder head. |

|

Installation Procedure |

|

Note: Tooling (B) must be used in order to install the valve guides to the correct height. |

|

Table 13 |

|

Height (X) from the top of the valve guide to the cylinder head surface ................ 35.00 ± 0.50 mm (1.378 ± 0.020 inch) |

|

Required Tools |

|

Tool A |

|

Part Number CVT0001 |

|

Part Description Valve Guide Driver Valve Guide Collar |

|

Qty 1 |

|

For more information, refer to Specifications, “Cylinder Head Valves”. |

|

B |

|

CVT0002 |

|

1 |

|

End By: |

|

NOTICE |

|

Keep all parts clean from contaminants. |

|

a. Install the inlet and exhaust valves. Refer to Disassembly and Assembly, “Inlet and Exhaust Valves - Remove and Install”. |

|

Contaminants may cause rapid wear and shortened component life. |

|

i02754779 Engine Oil Filter Base - Remove |

|

1. Lubricate the parent bores for the valve guides in the cylinder head with clean engine oil. |

|

Removal Procedure |

|

NOTICE Keep all parts clean from contaminants. |

|

Contaminants may cause rapid wear and shortened component life. |

|

g01383265 |

|

Illustration 43 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

|

KENR6906 |

|

25 Disassembly and Assembly Section |

|

NOTICE |

|

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, test- ing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before open- ing any compartment or disassembling any compo- nent containing fluids. |

|

Dispose of all fluids according to local regulations and mandates. |

|

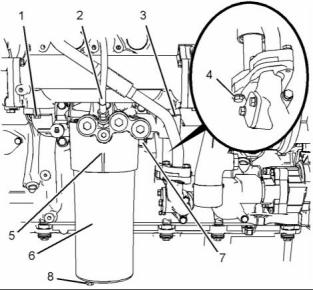

1. Place a suitable container below the engine oil filter base in order to drain the engine oil. |

|

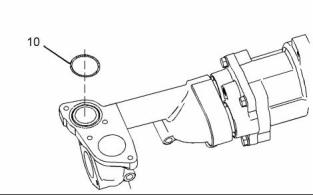

g01401581 |

|

Illustration 46 |

|

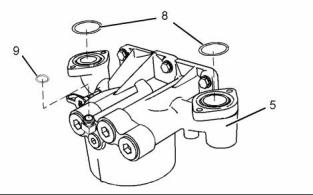

9. Remove O-ring seals (8) and O-ring seal (9) from engine oil filter base (5). |

|

g01404137 |

|

Illustration 47 |

|

10. Remove O-ring seal (10) from the engine oil pump. |

|

g01396094 |

|

Illustration 45 |

|

2. Remove plug (8). Allow the engine oil to drain. |

|

i02754781 Engine Oil Filter Base - Disassemble |

|

3. Remove engine oil filter (6) from engine oil filter base (5). Remove the O-ring seal and remove the filter element from the engine oil filter. Refer to Operation and Maintenance Manual, “Engine Oil and Filter - Change” for more information. |

|

4. Disconnect hose assembly (2) from engine oil filter base (5). |

|

Disassembly Procedure |

|

5. Remove bolts (1) and (3). |

|

Start By: |

|

6. Remove bolts (4) in order to disconnect the tube assembly from the engine oil pump. |

|

a. Remove the engine oil filter base. Refer to Disassembly and Assembly, “Engine Oil Filter Base - Remove”. |

|

7. Support the weight of the engine oil cooler. The engine oil cooler weighs approximately 23 kg (50 lb). |

|

NOTICE Keep all parts clean from contaminants. |

|

8. Remove engine oil filter base (5) and remove the joint. |

|

Contaminants may cause rapid wear and shortened component life. |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

|

26 |

|

KENR6906 |

|

Disassembly and Assembly Section |

|

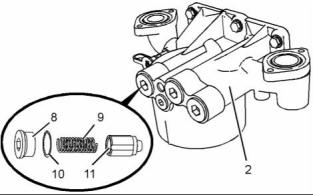

b. Remove spring (9). |

|

c. Remove plunger (11). |

|

Personal injury can result from being struck by parts propelled by a released spring force. |

|

Make sure to wear all necessary protective equip- ment. |

|

Follow the recommended procedure and use all recommended tooling to release the spring force. |

|

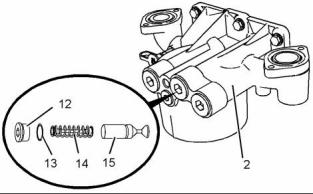

g01396108 |

|

Illustration 50 |

|

4. Follow Steps 4.a through 4.c in order to remove the oil cooler bypass valve. |

|

a. Remove plug (12) from engine oil filter base (2). Remove O-ring seal (13) from plug (12). |

|

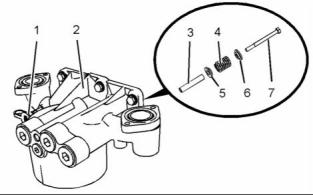

g01380571 |

|

Illustration 48 |

|

b. Remove spring assembly (14). c. Remove plunger (15). |

|

1. If necessary, remove oil sampling valve (1) from engine oil filter base (2). Remove the O-ring seal from the oil sampling valve. |

|

2. Follow Steps 2.a and 2.b in order to remove the high pressure relief valve. |

|

a. Remove bolt (7) from engine oil filter base (2). |

|

b. Remove cap (6), spring (4), seat (5) and sleeve (3) from engine oil filter base (2). |

|

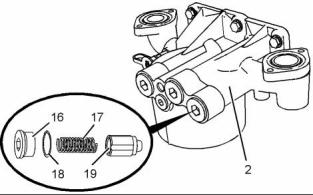

g01396110 |

|

Illustration 51 |

|

5. Follow Steps 5.a through 5.c in order to remove the oil pump bypass valve. |

|

a. Remove plug (16) from engine oil filter base (2). Remove O-ring seal (18) from plug (16). |

|

b. Remove spring (17). c. Remove plunger (19). |

|

g01396109 |

|

Illustration 49 |

|

3. Follow Steps 3.a through 3.c in order to remove the oil filter bypass valve. |

|

a. Remove plug (8) from engine oil filter base (2). Remove O-ring seal (10) from plug (8). |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

|

KENR6906 |

|

27 Disassembly and Assembly Section |

|

i02754782 |

|

Engine Oil Filter Base - Assemble |

|

Assembly Procedure |

|

NOTICE Keep all parts clean from contaminants. |

|

Contaminants may cause rapid wear and shortened component life. |

|

g01396108 |

|

Illustration 53 |

|

3. Follow Steps 3.a through 3.d in order to install the oil cooler bypass valve. |

|

Improper assembly of parts that are spring loaded can cause bodily injury. |

|

a. Lubricate spring assembly (14), and plunger (15) with clean engine oil. |

|

To prevent possible injury, follow the established assembly procedure and wear protective equip- ment. |

|

b. Install spring assembly (14), and plunger (15) into engine oil filter base (2). |

|

c. Install a new O-ring seal (13) to plug (12). |

|

1. Inspect the components for wear or damage. Replace any components that are worn or damaged. |

|

d. Install plug (12) to engine oil filter base (2). Tighten the plug to a torque of 100 N·m (74 lb ft). |

|

g01396110 |

|

Illustration 52 |

|

g01396109 |

|

Illustration 54 |

|

2. Follow Steps 2.a through 2.d in order to install the oil pump bypass valve. |

|

4. Follow Steps 4.a through 4.d in order to install the oil filter bypass valve. |

|

a. Lubricate plunger (19) and spring (17) with clean engine oil. |

|

a. Lubricate plunger (11) and spring (9) with clean engine oil. |

|

b. Install plunger (19) and spring (17) into engine oil filter base (2). |

|

b. Install plunger (11) and spring (9) into engine oil filter base (2). |

|

c. Install a new O-ring seal (18) to plug (16). |

|

c. Install a new O-ring seal (10) to plug (8). |

|

d. Install plug (16) to engine oil filter base (2). Tighten the plug to a torque of 100 N·m (74 lb ft). |

|

d. Install plug (8) to engine oil filter base (2). Tighten the plug to a torque of 100 N·m (74 lb ft). |

|

This document has been printed from SPI². Not for Resale |