產(chǎn)品中心

Perkins2306柴油發(fā)動機威爾遜P550柴油發(fā)電機配件CH10929濾清器

詳細描述

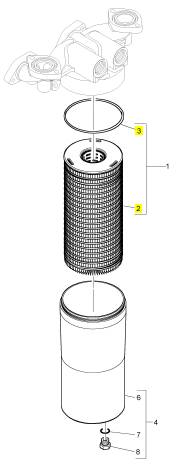

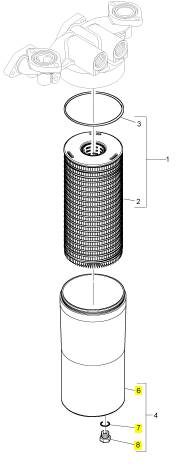

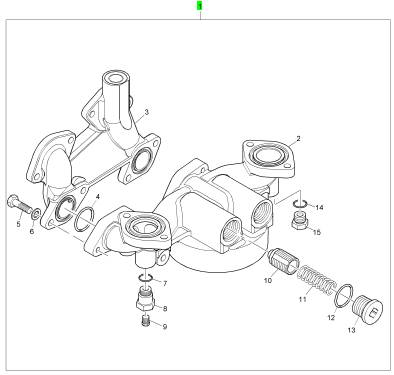

項目 零配件號碼 新件號 描述

CH11139 1 CH12010 密封O型圈

1 CH10929 1 CH10929 濾清器

1 CH10929 1 CH10929 濾清器

4 KRP1719 1 KRP1719 濾清器組合 01/12/2011

4 KRP1570 1 KRP1719 過濾器殼 30/11/2011

項目 零配件號碼 新件號 描述

2 1 濾清器

3 CH12010 1 CH12010 密封墊

項目 零配件號碼 新件號 描述

6 1 過濾器殼

7 CH10046 1 CH10046 密封O型圈

8 CH10284 1 CH10284 栓塞

項目 零配件號碼 新件號 描述

1 CH11250 1 CH11250 燃油濾清器

項目 零配件號碼 新件號 描述

2 1 燃油濾清器

3 CH10818 1 CH10818 燃油濾清器

4 CH10316 2 CH10316 密封O型圈

5 CH10567 4 CH10567 螺拴

6 CH10541 4 CH10255 墊圈

7 CH10133 1 CH10133 密封O型圈

8 CH10888 1 CH10888 承接器

9 CH10262 1 CH10262 栓塞

10 CH10513 2 CH10513 放泄閥

11 CH10819 2 CH10819 彈簧

12 CH10091 2 CH10091 密封O型圈

13 CH10291 2 CH10291 栓塞

14 CH10133 1 CH10133 密封O型圈

15 CH10284 1 CH10284 栓塞

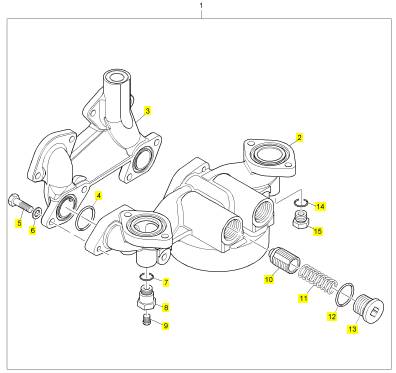

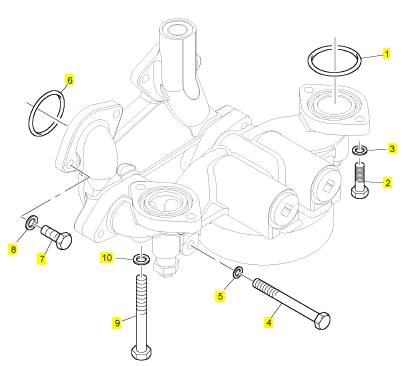

項目 零配件號碼 新件號 描述

1 T400222 2 T400222 密封O型圈

1 CH10816 2 CH10816 密封O型圈

2 CH10567 2 CH10567 螺拴

3 CH10255 2 CH10255 墊圈

3 CH10541 2 CH10255 墊圈

4 CH10814 2 CH10814 螺拴

5 CH10255 2 CH10255 墊圈

5 CH10541 2 CH10255 墊圈

6 CH10224 2 CH10224 密封O型圈

7 CH10815 4 CH10815 螺拴

8 CH10255 4 CH10255 墊圈

8 CH10541 4 CH10255 墊圈

9 CH10751 2 CH10751 螺拴

10 CH10255 2 CH10255 墊圈

10 CH10541 2 CH10255 墊圈

Note: A sight glass in the low pressure supply line is

helpful in diagnosing air in the fuel.

4. Cold weather adversely affects the characteristics

of the fuel. Refer to the Operation and

Maintenance Manual for information on improving

the c haracteristics of the fuel during cold weather

operation.

5. Check the fuel pressure during engine cranking.

Check the fuel pressure after the fuel filter. Refer

to Systems Operation, Testing and Adjusting,

“Fuel System” for the correct pressure values. If

the fuel pressure is low, replace the fuel filters. If

the fuel pressure is still low, check the following

items: fuel transfer pump, fuel transfer pump

coupling, and fuel press ure regulating valve.

Air Inlet and Exhaust System

1. Check for an air filter restriction. Clean plugged air

filters or replace plugged air filters. Refer to the

Operation and Maintenance Manual for additional

information.

2. Check the air inlet and exhaust system for

restrictions and/or for leaks. Refer to Systems

Operation, Testing and Adjusting, “Air Inlet and

Exhaust System”.

i02557763

Engine Oil in Cooling System

Probable Causes

• Engine oil cooler core

• Cylinder head gasket

Recommended Actions

Engine Oil Cooler Core

1. Inspect the engine oil cooler c ore for leaks. If a

leak is found, replace the oil cooler core. Refer to

Disassembly and Assembly, “Engine Oil Cooler

- Remove” and Disassembly and Assembly,

“Engine Oil Cooler - Install”.

2. Drain the crankcase and refill the crankcase with

clean engine oil. Ins tall new engine oil filters.

Refer to the Operation and Maintenance Manual

for more information.

Cylinder Head Gasket

1. Remove the cylinder head. Refer to Disassembly

and Assembly, “Cylinder Head - Remove” for the

correct procedure.

2. Check the cylinder liner projection. Refer to

Systems Operation, Testing and Adjusting for the

correct procedure.

3. Install a new cylinder head gasket and new water

seals in the spacer plate. Refer to Disassembly

and Assembly, “Cylinder Head - Install” for the

correct procedure.

i02557773

Engine Vibration

Probable Causes

• Vibration damper

• Engine supports

• Driven equipment

• Engine misfiring or running rough

Recommended Actions

Vibration Damper

Check the vibration damper for damage. Install a

new vibration damper, if necessary. Inspect the

mounting bolts for damage and/or for wear. Replace

any damaged bolts. Refer to the Disassembly and

Assembly manual.

Engine Supports

Inspect the mounts and the brackets while you run

the engine through the speed range. Look for mounts

and brackets that are loose and/or broken. Tighten

all of the mounting bolts. Install new components, if

nec essary.

Driven Equipment

Check the alignment and the balance of the driven

equipment.

Engine Misfiring or Running Rough

Refer to the Troubleshooting Guide, “Engine Misfires,

Runs Rough or Is Unstable”.

This document has been printed from SPI². Not for Resale

![]() 40

40

Troubleshooting Section

KENR6224

Engine Will

Not Crank

i02557776

Hydraulic Cylinder Lock

Check for fluid in the cylinders (hydraulic cylinder

lock) by removing the individual electronic unit

injectors.

Note: Drain the fuel from the cylinder head. Fuel will

Probable Causes

• Batteries

• Battery cables

• Starting circuit

• Starting motor solenoid

• Starting motor

• Flywheel ring gear

• Hydraulic cylinder lock

• Internal engine fault

Recommended Actions

Batteries and/or Battery Cables

1. Inspect the main power switch, battery posts,

and battery cables for loose connections and

for corrosion. If the battery cables are corroded,

remove the battery cables and clean the battery

cables. Tighten any loose connections.

2. Inspect the batteries.

a. Charge the batteries. Refer to local operating

procedures.

b. Load test the batteries. Refer to local operating

procedures.

Starting Motor Solenoid or Starting

Circuit

1. Test the operation of the starting motor solenoid.

2. Check the wiring to the starting motor solenoid.

Starting Motor or Flywheel Ring Gear

1. Test the operation of the starting motor.

2. Inspect the pinion on the starting motor pinion and

the flywheel ring gear for damage.

flow from the cylinder head into the cylinders when

the electronic unit injector is removed.

Internal Engine Fault

Disassemble the engine. Refer to the Disassembly

and Ass embly manual. Inspect the internal

components for the following conditions:

• Seizure

• Broken components

• Bent components

i02557812

Excessive Black Smoke

Probable Causes

• Flash file

• Position sensors

• Atmospheric pres sure sensor

• Inlet manifold pressure sensor

• “Fuel Position” and/or “FRC Fuel Limit”

• Fuel quality

• Valve adjustment

• Air inlet or exhaust system

Recommended Actions

Flash File

Verify that the correct flash file is installed. Refer to

the Troubleshooting Guide, “Flash Programming” for

information.

Position Sensors

1. Check the calibration of the position sensors.

Refer to Troubleshooting, “Engine Position

Sensors - Calibrate”.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

41

Troubleshooting Section

2.

Verify that the crankshaft and the camshaft drive

gears are set with the proper orientation. Refer to

a.

Check for an air filter restriction.

the Disassembly and Assembly manual.

Atmospheric Pressure Sensor

1. Remove the sensor.

2. Remove debris, moisture, or ice from the sensor.

3. Install the sensor.

4. Check the electronic service tool for active

diagnostic codes on the sensor. If no active

diagnostic code exists, the sensor may be used.

The correct reading for the atmospheric pressure

is between 50 kPa (7.25 psi) and 100 kPa

2.

3.

4.

b. Perform a visual inspection of the system for

restrictions and/or for leaks in the air inlet

piping .

Ensure that the turbocharger is in good repair.

Check the exhaust sy stem for restrictions.

Repair any leaks that were found. Remove

any restrictions that were found. Replace any

damaged components that were found.

i02558234

(14.5 psi).

Excessive

Engine

Oil

Inlet Manifold Pressure Sensor, “Fuel

Position”, and/or “FRC Fuel Limit”

1. Monitor the status of “Fuel Position” and “Rated

Fuel Limit” while the engine is operating under full

load. If “Fuel Position” equals “Rated Fuel Limit”

and “Fuel Position” is less than “FRC Fuel Limit”,

the Electronic Control Module (ECM) is providing

the correct control. Otherwise, proceed to the next

Step.

2. Verify that there are no active diagnostic codes for

the inlet manifold pressure sensor.

3. Monitor the status of “Boost Pressure” and

“Atmospheric Pressure” on the electronic service

tool. When the engine is not running, “Boost

Pressure” should be 0 kPa (0 psi).

Note: A fault with the “FRC Fuel Limit” will only cause

black smoke during acceleration. A fault with the

“FRC Fuel Limit” will not cause black smoke during

steady state operation.

Fuel Quality

Cold weather adversely affects the characteristics

of the fuel. Refer to the Operation and Maintenance

Manual for information on improv ing the

characteristics of the fuel during cold weather

operation.

Valve Adjustment

Check the valve adjustment. Refer to Sy stems

Operation, Testing and Adjusting for information on

valve adjustments.

Air Inlet or Exhaust System

1. Check the air inlet system for restrictions and/or

for leaks.

Consumption

Probable Causes

• Oil leaks

• Oil level

• Engine oil cooler

• Turbocharger

• Valve guides

• Piston rings

• Incorrect installation of the compression ring and/or

the intermediate ring

Recommended Actions

Oil Leaks

Loc ate all oil leaks. Repair the oil leaks . Chec k for a

dirty crankcase breather.

Oil Level

Inspect the engine oil level. Remove any extra oil

from the engine. Recheck all fluid levels.

Engine Oil Cooler

Check for leaks in the engine oil cooler. Check for oil

in the engine coolant. If necessary, repair the engine

oil cooler.

This document has been printed from SPI². Not for Resale

![]() 42

42

Troubleshooting Section

KENR6224

Turbocharger

Check the air inlet manifold for oil. Check for oil

leakage past the seal rings in the impeller end of

the turbocharger shaft. If necessary, repair the

turbocharger.

Valve Guides

If the valve guides are worn, repair the cylinder head.

Refer to Disassembly and Assembly, “Inlet and

Exhaust Valve Guides - Remove and Install”.

Piston Rings or Incorrect Installation

of the Compression Ring and/or the

Intermediate Ring

Inspect the internal engine components. Replace any

worn components.

i02558236

Excessive Fuel Consumption

Probable Causes

• Engine operation

• Fuel leaks

• Fuel quality

• Engine speed/timing

• Electronic unit injectors

• Air inlet and exhaust system

• Accessory equipment

Recommended Actions

Engine Operation

Use the electronic serv ice tool to check the “Current

Totals” for a high load factor which would be indicative

of poor operating habits.

Note: Engine operation may also be affected by

environmental conditions such as wind and snow.

Fuel Leaks

Check the fuel pressure during engine cranking.

Check the fuel pressure after the fuel filter. Refer to

Systems Operation, Testing and Adjusting for the

correct pressure values. If the fuel pressure is low,

replace the fuel filters. If the fuel pressure is still low,

check the following items : fuel transfer pump, fuel

transfer pump coupling, and fuel pressure regulating

valve.

Fuel Quality

Cold weather adversely affects the characteristics

of the fuel. Refer to the Operation and Maintenance

Manual for information on improving the

characteristics of the fuel during cold weather

operation.

Engine Speed/Timing

Perform a calibration of the position sensor. Refer to

the Troubleshooting Guide, “Engine Position Sensor

- Calibrate”.

Electronic Unit Injectors

1. Check for correct installation of the J1/P1

and J2/P2 Electronic Control Module (ECM)

connectors and the electronic unit injector

connectors. Refer to the Troubleshooting Guide,

“Electrical Connectors - Inspect”.

2. Perform the “Injector Solenoid Test” on the

electronic s ervice tool in order to determine if all

of the injector solenoids are being energized by

the ECM.

3. Perform the “Cylinder Cutout Test” on the

electronic service tool in order to identify any

injectors that might be misfiring. Refer to the

Troubleshooting Guide, “Injector Solenoid Circuit

- Test”.

Air Inlet and Exhaust System

1. Inspect the air filter for a restriction. If the air filter

shows signs of being plugged, clean the air filter

or replace the air filter.

2. Check the air inlet and exhaust system for

restrictions and/or for leaks. Refer to Systems

Operation, Testing and Adjusting.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

43

Troubleshooting Section

Accessory Equipment

Check all accessory equipment for faults that may

create excess ive load on the engine. Repair any

damaged components or replace any damaged

components.

Note: If the camshaft is replaced, the valve lifters

must also be replaced.

3. Adjust the engine valve lash. Refer to Systems

Operation, Testing and Adjusting, “Engine Valve

Lash - Inspect/Adjust”.

Excessive

Valve Lash

i02558239

Excessive W hite

Smoke

i02558241

Probable Causes

• Lubrication

• Valve lash

• Valve train components

Recommended Actions

Lubrication

1. Remove the valve mechanism cover. Refer to

Disassembly and Assembly, “Valve Mechanism

Cover - Remove and Install”.

2. Check the lubrication in the valve compartment.

Ensure that there is adequate engine oil flow in

the valve compartment. The passages for the

engine oil must be clean.

Valve Lash

Adjust the engine valve lash. Refer to Systems

Operation, Testing and Adjusting, “Engine Valve Lash

- Inspect/Adjust”.

Valve Train Components

1. Inspect the following components of the valve

train:

• Roc ker arms

• Pushrods

• Valv e lifters

• Camshaft

• Valv e stems

• Roc ker shafts

2. Check the components for the following conditions:

abnormal wear, excessive wear, straightness, and

cleanliness. Replace parts, if necessary.

Note: Some white smoke may be pres ent during

cold start-up conditions when the engine is operating

normally. If the white smoke persists, there may be a

fault.

Probable Causes

• Diagnostic codes

• Flash file

• Starting aids

• Water temperature regulators

• Electronic unit injectors

• Fuel supply

• Cooling s ystem

• Component wear

Recommended Actions

Diagnostic Codes

Use the electronic servic e tool to check for active

diagnostic codes. Troubleshoot any active diagnostic

codes before continuing with this procedure.

Flash File

Verify that the correct flash file is installed in the

Engine Control Module (ECM). The flash file that

is installed in the ECM can be dis played on the

“Configuration” screen on the electronic service tool.

Starting Aids

Block Heater (If Equipped)

Ensure that the block heater is functioning correctly.

This document has been printed from SPI². Not for Resale

![]() 44

44

Troubleshooting Section

KENR6224

Water Temperature Regulators

Check the water temperature regulators for correct

operation. Refer to Systems Operation, Testing and

Adjusting, “Water Temperature Regulator - Test” for

the proper procedure.

Electronic Unit Injectors

Fuel Dilution of Engine

Probable Causes

Oil

i02558246

Use the electronic service tool to perform the cylinder

cutout test. Try to simulate the conditions for the test

that were experienced during operation. Cut out each

cylinder individually for approximately one minute in

order to isolate any misfiring cylinders. If the misfire

can be isolated to a specific cylinder, proceed to

Troubleshooting, “Injector Solenoid Circuit - Test”.

Fuel Supply

1. Monitor the exhaust for smoke while the engine

•

•

•

•

•

Seals on the case of the electronic unit injector or

on the barrel of the electronic unit injector

Seals on the fuel line adapter for the cylinder head

Electronic unit injector

Fuel supply manifold

Fuel transfer pump seal

2.

3.

4.

5.

is being cranked.

If no smoke is present, there may be a fault with

the fuel quality or there may be a fault in the fuel

supply.

Check the fuel pressure. Refer to Systems

Operation, Testing and Adjusting, “Fuel System

Pressure - Test”.

Ensure that the fuel system has been primed.

Refer to the Operation and Maintenance Manual,

“Fuel System - Prime” for the correct procedure.

Check for fuel supply lines that are restricted.

Cold weather adversely affects the characteristics

of the fuel. Refer to the Operation and

Maintenance Manual for information on improving

the c haracteristics of the fuel during cold weather

operation.

Recommended Actions

Seals on the Case of the Electronic Unit

Injector or on the Barrel of the Electronic

Unit Injector

Look for signs of damage to the seals for the

electronic unit injectors. Replace any seals that are

leaking.

Seals on the Fuel Line Adapter for the

Cylinder Head

Look for signs of damage to the seals on the fuel line

adapter for the cylinder head. Repair any leaking fuel

lines or components and/or replace any leaking fuel

lines or components.

Electronic Unit Injector

Look for signs of damage to the electronic unit

injectors. If necessary, repair the electronic unit

Cooling System

Check for an internal coolant leak. Check for coolant

in the engine oil, coolant in the cylinders, and coolant

in the exhaust system. Refer to Systems Operation,

Testing and Adjusting, “Cooling System - Test”.

Component Wear

Check the following components for excessive wear:

• Valves

• Pistons

• Rings

• Cylinder liners

injectors or replac e the electronic unit injectors.

Fuel Supply Manifold

Look for signs of damage to the fuel supply manifold.

Fuel Transfer Pump Seal

Ensure that the weep hole is not plugged. If

nec essary, repair the fuel transfer pump or replace

the fuel transfer pump.

This document has been printed from SPI². Not for Resale

|

45

Troubleshooting Section

Intermittent Engine

i02558247

Shutdown

•

•

•

J61/P61 Customer connectors

J300/P300 Connectors for the injector solenoid

harness

J401/P401 and J402/P402 Engine position

Note: Use this procedure only if the engine shut

down completely and it was necessary to res tart the

engine.

Probable Causes

• Diagnostic codes or event codes

• Operating c onditions

2.

sensor connectors

Check the associated wiring for the following

conditions: damage, abrasion, corrosion, and

incorrect attachment.

Refer to the Troubleshooting Guide, “Electrical

Connectors - Inspect”.

•

•

•

•

Electrical connections

Remote shutdown

Circuit breakers and fuses

Fuel supply

Note: Aftermarket engine protection devices usually

interrupt power to the ECM. Check for correct

installation and for operation of aftermarket engine

protection devices. It may be necessary to bypass

the aftermarket devices in order to continue testing.

Remote Shutdown

1. Access the s tatus screen that displays the remote

Note: If the fault only occurs under certain conditions

such as high engine speed, full load or engine

operating temperature, then perform the test under

those operating conditions.

Recommended Actions

2.

shutdown switch status. The remote shutdown

switch status on the electronic service tool is

called “Injection Disable”.

Refer to Table 8 and measure the voltage between

each terminal that is listed and the engine ground.

Diagnostic Codes or Event Codes

Certain diagnostic codes and/or event codes may

cause the engine to shutdown. Connect the electronic

servic e tool and check for active codes and/or for

logged codes. Troubleshoot any codes that are

present before continuing with this procedure.

Operating Conditions

The engine may be shut down due to low pressure

levels or other factors. Connect the electronic service

tool and c heck for active shutdowns or diagnostic

codes.

If a shutdown is ac tive, “Injection Disabled” will

appear in the third box of any status screen on the

electronic service tool.

An engine shutdown event will appear on a J1939

device if the device is capable of displaying diagnostic

codes.

Electrical Connect ions

1. Check the following connectors for proper

ins tallation:

• J1/P1 and J2/P2 connectors for the Electronic

Control Module (ECM)

Table 8

3. If the voltage is not in the proper range, refer to

Troubleshooting, “Switch Circuits - Test”.

Circuit Breakers and Fuses

Check the circuit breakers and fuses. The circuit

breakers may exceed the trip point due to

overheating. Reset the circuit breakers if the circuit

breakers are tripped. Replace any blown fuses.

Fuel Supply

Check for a fault in the fuel supply. Verify that the

fuel pressure is correct. Refer to Systems Operation,

Testing and Adjusting, “Fuel System Pressure - Test”

for additional information.

This document has been printed from SPI². Not for Resale

![]()

![]() 46

46

Troubleshooting Section

KENR6224

Low Engine Oil Pressure

NOTICE

i02558254

Oil Cooler

Check the oil cooler for plugging or blockage. Clean

the oil cooler core. If necessary, replace the engine

oil cooler. Refer to Disas sembly and Assembly, “Oil

Cooler - Remove” and Disassembly and Assembly,

“Oil Cooler - Install”.

Do not operate engine with low oil pressure. Engine

damage will result. If measured engine oil pressure

is low, discontinue engine operation until the fault is

corrected.

Probable Causes

• Engine oil level

• Engine oil filters and oil filter bypass valve

• Engine oil pump

• Engine oil cooler

• Fuel dilution

• Engine wear

Recommended Actions

Engine Oil Level

Inspect the engine oil level. If engine oil is low add

engine oil. Refer to the Operation and Maintenance

Manual.

Engine Oil Filters and Oil Filter Bypass

Valve

Check the service records of the engine for

information that is related to the last oil change. If

necessary, perform an oil change on the engine and

replace the engine oil filters.

Check the operation of oil filter bypass valve. Clean

the bypass valve and the housing. If necessary,

install new parts.

Engine Oil Pump

Check for blockage of the inlet screen for the engine

oil pump. Check the components of the engine oil

pump for excessive wear. If necessary, repair the oil

pump or replace the oil pump.

|

Check for presence of fuel in lubricating oil. Refer to

the Troubleshooting Guide, “Fuel Dilution of Engine

Oil”.

Engine Wear

Inspect the camshaft and/or camshaft bearings

for excessive wear. Inspect the crankshaft and/or

crankshaft bearings. Excessive wear to discrete

components may be an indication of a blocked oil

pas sage. Use an oil pressure gauge to check the

oil pressure at the main oil gallery. This will help

determine if the excessive wear is from low system

pressure or from passages that are blocked.

i02558264

Low Power

Probable Causes

• Diagnostic codes

• Event codes

• Engine rating

• Programmable parameters

• Cold mode

• Electrical connectors

• Circuit for electronic unit injectors

• Fuel supply

and/or FRC fuel position

• Air inlet and exhaust system

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

47

Troubleshooting Section

Recommended Actions

Note: If the fault only occurs under certain conditions ,

test the engine under those conditions. Examples

of certain conditions are high rpm, full load and

engine operating temperature. Troubleshooting

the symptoms under other conditions can give

misleading results.

Diagnostic Codes and Event Codes

Certain diagnostic codes and/or event codes may

cause poor performance. Connect the electronic

service tool and check for active codes and for logged

codes. Troubleshoot any codes that are present

before continuing with this procedure.

Engine Rating

Verify that the correct engine rating is being used for

the application.

Programmable Parameters

Check the following parameter on the electronic

service tool:

• Desired speed input

Verify that the injector trim files are programmed.

Cold Mode

Monitor the status screen on the electronic service

tool in order to verify that the engine has exited cold

mode. Observe the reading for coolant temperature

on the electronic service tool. The engine should

exit cold mode whenever the coolant temperature is

above 18 °C (64 °F).

Electrical Connectors

Check the associated wiring for damage, abrasion,

corrosion or incorrect attachment on the following

connectors. J1/P1 and J2/P2 ECM connectors,

J61/P61 customer connector (optional), and

J403/P403 throttle position sensor connector. Refer

to the Troubleshooting Guide, “Electrical Connectors

- Inspect” for additional information.

Circuit for the Electronic Unit Injector

Inspect the J2/P2 ECM connector and the J300/P300

electronic unit injector connector for proper

connections. Refer to the Troubleshooting Guide,

“ Electrical Connectors - Inspect”. Cut out each

cylinder in order to isolate a misfiring cylinder or

cylinders. If the results are inconclusive, shut off half

of the cylinders and repeat the cylinder cutout test

on the active cylinders that are remaining in order to

locate those c ylinders that are missing. Refer to the

Troubleshooting Guide, “Injector Solenoid Circuit -

Test”.

Fuel Supply

Check for a fault in the fuel supply and verify the fuel

pressure. For further information, refer to Systems

Operation, Testing and Adjus ting, “Fuel Sy stem

Pressure - Test”.

Inlet Manifold Pressure Sensor, Rated

Fuel Position and/or FRC Fuel Position

1. With the engine at full load, monitor “Fuel Position”

and “Rated Fuel Limit” on the status screen. If

“Fuel Position” does not equal “Rated Fuel Limit”,

then check air inlet manifold pressure.

2. Verify that there are no active diagnostic codes

that are associated with the inlet manifold pressure

sensor or with the atmospheric pressure sens or.

3. Monitor air inlet manifold pressure and

atmospheric press ure for normal operation on the

status screen.

Air Inlet and Exhaust System

Check the air inlet and exhaust systems for

restrictions and for leaks . Refer to Systems

Operation, Testing and Adjusting, “Air Inlet and

Exhaust System”. Look for an indication of the

warning lamp or restriction indicators that are tripped

if the filters are equipped with these devices. These

indicators are associated with plugged filters. Replace

the plugged air filters or clean the plugged air filters.

Refer to the Operation and Maintenance Manual.

Repair any leaks that are found in the system.

i02558272

Mechanical Noise (Knock) in

Engine

Probable Causes

• Driven equipment

This document has been printed from SPI². Not for Resale

![]() 48

48

Troubleshooting Section

KENR6224

•

•

•

•

Gear train

Cylinder head and related components

Crankshaft and related components

Pistons

Noise

Coming

i02558282

from Cylinder

Recommended Repairs

Driven E quipment

Inspect the alignment and the balance of the driven

equipment. Inspect the coupling. If necessary,

disconnect the driven equipment and test the engine.

Gear Train

Inspect the condition of the gear train.

Inspect the engine oil filters for nonferrous material.

Flaking of nonferrous material could indicate worn

gear train bearings.

Cylinder Head and Related Components

Inspect the components of the valve train for good

condition. Check for signs of damage and/or wear

to the valves, cylinder head gasket, etc. Inspect the

condition of the camshafts. If a camshaft is replaced,

new valve lifters must be installed.

Crankshaft

Inspect the crankshaft and the related components.

Inspect the connecting rod bearings and the bearing

surfaces on the crankshaft. Make sure that the

bearings are in the correct position.

Look for worn thrust plates and wear on the

crankshaft.

Check the counterweight bolts.

Pistons

Make sure that the piston pins are correctly installed.

Inspect the pistons for wear or damage.

Probable Causes

• Diagnostic codes

• Fuel quality

• Electronic unit injectors

• Valve lash

Recommended Actions

Diagnostic Codes

Check for active diagnostic c odes on the electronic

service tool. Troubleshoot any active diagnostic

codes before continuing with this procedure.

Fuel Quality

Refer to the Operation and Maintenance Manual for

information on the characteristics of the fuel.

Electronic Unit Injectors

1. Check the connectors on the Electronic Control

Module (ECM). Check for correct installation of

the J1/P1 and J2/P2 ECM connectors. Inspect the

unit injector wiring harness from the ECM to the

J300/P300 valve cover entry connector. Refer to

the Troubleshooting Guide, “Electrical Connectors

- Inspect”.

2. Perform the “Injector Solenoid Test” on the

electronic service tool in order to determine if all

of the injector solenoids are being energized by

the ECM. Refer to the Troubleshooting Guide,

“Injector Solenoid Circuit - Test”.

3. Perform the “Cylinder Cutout Test” on the

electronic service tool in order to identify any

injectors that may be misfiring.

Valve Lash

Check the engine valve lash settings. Inspect the

valve train for sufficient lubrication. Check damage to

valve train components which may cause excessive

valve las h. Repair any faults that are found. Refer to

the Troubleshooting Guide, “Excessive Valve Lash”.

This document has been printed from SPI². Not for Resale

![]()

![]() KENR6224

KENR6224

49

Troubleshooting Section

i02558285

Poor Acceleration or Response

Probable Causes

3.

Perform the cylinder cutout test on the electronic

service tool in order to identify any injectors that

might be misfiring. Refer to Troubleshooting,

“Injector Solenoid Circuit - Test” for the proper

procedure.

•

•

•

•

•

•

•

Cold mode operation

Flash file

Electrical connectors

Electronic unit injectors

Fuel Position, Rated Fuel Limit, and FRC Fuel

Position

Air inlet and exhaust system

Fuel supply

Fuel P osition, Rated Fuel Limit, and FRC

Fuel Position

1. Monitor the status of “Fuel Position” and “Rated

Fuel Limit” while the engine is operating under full

load. If “Fuel Position” equals “Rated Fuel Limit”

and “Fuel Position” is less than “FRC Fuel Limit”,

the electronics are operating correctly. Otherwise,

proceed to the next Step.

2. Verify that there are no active diagnostic codes for

the inlet manifold pressure sensor.

3. Monitor the “Intake Manifold Pressure” and

“Atmospheric Pressure” for normal operation.

When the engine is not running, “Boost Pressure”

should be 0 kPa (0 psi).

Recommended Actions

Cold Mode Operat ion

Monitor the status screen on the electronic service

tool in order to verify that the engine has exited cold

mode. Observe the reading for coolant temperature

on the electronic service tool. The engine should

exit cold mode whenever the coolant temperature is

above 18 °C (64 °F).

Flash File

Verify that the correct flash file is installed.

Electrical Connectors

Check for correct installation of the J1/P1 and J2/P2

connectors for the Electronic Control Module (ECM).

Check for correct installation of the JH300/P300

electronic unit injector connectors. Refer to the

Troubleshooting Guide, “Electrical Connec tors -

Inspect”.

Electronic Unit Injectors

1. Use the electronic service tool to determine if

there are any active diagnostic codes for the

electronic unit injectors.

2. Perform the injector solenoid test on the electronic

service tool in order to determine if all of the

injector solenoids are being energized by the

ECM. Refer to Troubleshooting, “Injector Solenoid

Circuit - Test” for the proper procedure.

Air Inlet and Exhaust System

1. Check for an air filter restriction indicator. Clean

plugged air filters or replace plugged air filters.

Refer to the Operation and Maintenance Manual.

2. Check the air inlet and exhaust system for

restrictions and/or leaks. Refer to Systems

Operation, Testing and Adjusting, “Air Inlet and

Exhaust System”.

Fuel Supply

1. Check the fuel lines for the following faults:

restrictions, collapsed lines , and pinched lines. If

faults are found with the fuel lines, repair the lines

and/or replace the lines.

2. Check the fuel tank for foreign objects which may

block the fuel supply.

NOTICE

Do not crank the engine continuously for more than

30 seconds . Allow the starting motor to cool for two

minutes before cranking the engine again.

3. Prime the fuel system if any of the following

procedures have been performed:

• Replacement of the fuel filters

• Service on the low pressure fuel supply circuit

• Replacement of electronic unit injectors

This document has been printed from SPI². Not for Resale

![]() 50

50

Troubleshooting Section

KENR6224

Note: A sight glass in the low pressure supply line is

helpful in diagnosing air in the fuel. Refer to Systems

Operation, Testing and Adjusting, “Air in Fuel - Test”

for more information.

4. Cold weather adversely affects the characteristics

of the fuel. Refer to the Operation and

Maintenance Manual for information on improving

the c haracteristics of the fuel during cold weather

operation.

5. Check the fuel pressure a, fter the fuel filter while

the engine is being cranked. Refer to Systems

Operation, Testing and Adjusting for the correc t

pressure values. If the fuel pressure is low,

replace the fuel filters. If the fuel pressure is

still low, check the following items: fuel transfer

pump, fuel transfer pump coupling, and fuel

pressure regulating valve. Refer to Systems

Operation/Testing and Adjusting for more

information.

Valve

Rotator or Spring

i02558323

Lock

Is

Free

Probable Causes

• Valve rotator

• Spring locks

• Valve springs

• Valves

Recommended Actions

1. Determine the cause of an engine ov erspeed that

would crack the valve rotator. Repair the condition.

2. Inspect the following components for damage:

• Valv e rotators

• Spring locks

• Valv e springs

• Valv es

Note: Ensure that the valve has not contacted the

piston. If the valve has contacted the piston, check

the exhaust sys tem for debris.

3. Replace any damaged components.

This document has been printed from SPI². Not for Resale