產(chǎn)品中心

美國強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢圖冊

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國道依茨 韓國大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

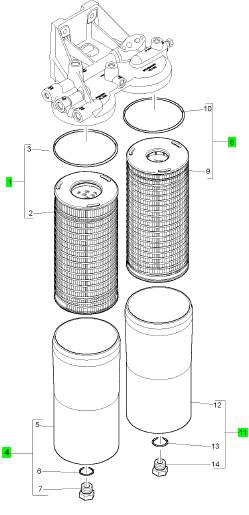

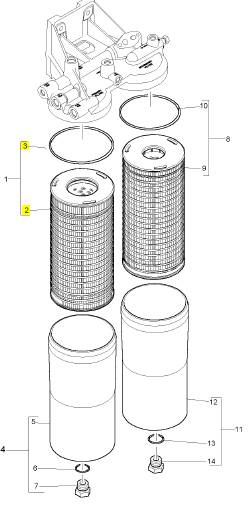

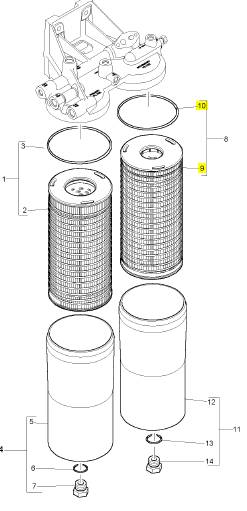

Perkins2306柴油發(fā)動(dòng)機(jī)威爾遜P550柴油發(fā)電機(jī)配件CH10931燃油過濾器

詳細(xì)描述

項(xiàng)目 零配件號碼 新件號 描述

1 CH10930 1 CH10930 前燃料過濾器

4 CH11094 1 檢查歷史 過濾器殼

8 CH10931 1 CH10931 燃料過濾器

11 CH11096 1 檢查歷史 燃料過濾器殼

項(xiàng)目 零配件號碼 新件號 描述

2 1 燃料過濾器機(jī)械要素

3 CH12010 1 CH12010 密封墊

項(xiàng)目 零配件號碼 新件號 描述

9 1 燃料過濾器機(jī)械要素

10 CH12010 1 CH12010 密封墊

項(xiàng)目 零配件號碼 新件號 描述

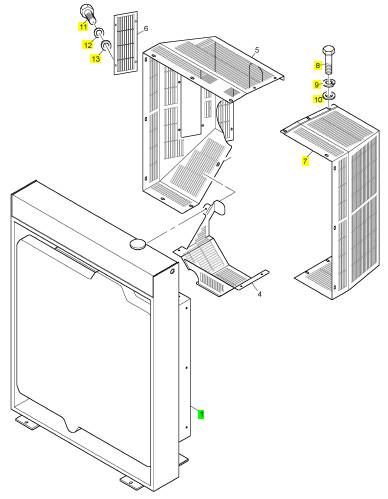

1 CH11247 1 CH11247 散熱器

1 CH11247 1 CH11247 散熱器

7 CH11167 1 CH11167 風(fēng)扇守衛(wèi)

8 CH11151 1 CH11151 風(fēng)扇守衛(wèi)

9 CH11047 1 CH11047 風(fēng)扇守衛(wèi)

10 CH11152 1 CH11152 風(fēng)扇守衛(wèi)

11 CV70401 20 CV70401 固定螺釘

12 CV70395 20 CV70395 彈簧塾圈

13 CV70392 20 CV70392 墊圈

14 CV70507 4 CV70507 固定螺釘

15 CV70509 4 CV70509 彈簧塾圈

16 CV70508 4 CV70508 墊圈

項(xiàng)目 零配件號碼 新件號 描述

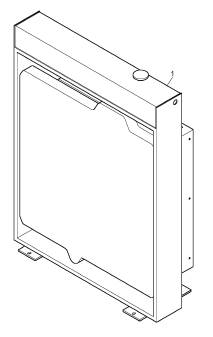

1 CH11247 1 CH11247 散熱器

1 CH11247 1 CH11247 散熱器

項(xiàng)目 零配件號碼 新件號 描述

CV25002 1 CH12822 管集箱箱

Y06/00017 1 CH12825 散熱器蓋

2 CH12819 1 CH12819 加料冷卻器

3 CH12822 1 CH12822 管集箱箱

4 CH12825 1 CH12825 散熱器蓋

5 CH12828 2 CH12828 水管 -冷卻器

6 CH12830 4 CH12830 水管夾

Troubleshooting

2506- 15

Industrial

Engine

MGA (Engine)

MGB (Engine)

MGD (Engine)

This document has been printed from SPI². Not for Resale

![]()

![]() Important Safety

Important Safety

Information

Most accidents that involve product operation, maintenance and repair are caused by failure to

observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially

hazardous situations before an accident occurs. A person must be alert to potential hazards. This

person should also have the necessary training, skills and tools to perform these functions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard

warnings are not heeded, bodily injury or death could occur to you or to other persons.

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as

“DANGER”, “WARNING” or “CAUTION”. The Safety Alert “WARNING” label is shown below.

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is Involved.

The message that appears under the warning explains the hazard and can be either written or

pictorially presented.

Operations that may cause product damage are identified by “NOTICE” labels on the product and in

this publication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The information, specifications, and illustrations in this publication are on the basis of information that

was available at the time that the publication was written. The specifications, torques, pressures,

measurements, adjustments, illustrations, and other items can change at any time. These changes can

affect the service that is given to the product. Obtain the complete and most current information before

you start any job. Perkins dealers or Perkins distributors have the most current information available.

When

replacement

parts

are

required

for

this

product Perkins recommends using Perkins

replacement parts.

Failure to heed this warning can lead to prema-

ture failures, product damage, personal injury or

death.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

3

Table of Contents

Table

of

Contents

CID 0003 FMI 11 ................................................... 55

CID 0004 FMI 11 ................................................... 55

CID 0005 FMI 11 ................................................... 56

CID 0006 FMI 11 ................................................... 56

Troubleshoot ing Section

Electronic Troubleshooting

System Overview .................................................... 5

Glossary .................................................................. 7

Electronic Service Tools ........................................ 10

Replacing the ECM ............................................... 12

Self-Diagnostics .................................................... 13

Sensors and Electrical Connectors ....................... 14

Engine Wiring Information .................................... 18

Programming Parameters

Programming Parameters ..................................... 21

Factory Passwords ............................................... 21

Factory Passwords Worksheet ............................. 21

Flash Programming .............................................. 22

Injector Trim File ................................................... 23

System Configuration Parameters

System Configuration Parameters ........................ 24

Troubleshooting without a Diagnostic Code

Alternator Noise .................................................... 31

Alternator Will Not Charge .................................... 31

Battery .................................................................. 31

Can Not Reach Top Engine RPM ......................... 32

Coolant in Engine Oil ............................................ 33

Coolant Temperature Is Too High ......................... 34

ECM Will Not Accept Factory Passwords ............. 34

ECM Will Not Communicate with Other Systems or

Display Modules .................................................. 34

Electronic Service Tool Will Not Communicate with

ECM .................................................................... 35

Engine Cranks but Will Not Start .......................... 36

Engine Has Early Wear ........................................ 37

Engine Misfires, Runs Rough or Is Unstable ........ 38

Engine Oil in Cooling System ............................... 39

Engine Vibration ................................................... 39

Engine Will Not Crank ........................................... 40

Excessive Black Smoke ........................................ 40

Excessive Engine Oil Consumption ...................... 41

Excessive Fuel Consumption ............................... 42

Excessive Valve Lash ........................................... 43

Excessive White Smoke ....................................... 43

Fuel Dilution of Engine Oil .................................... 44

Intermittent Engine Shutdown ............................... 45

Low Engine Oil Pressure ...................................... 46

Low Power ............................................................ 46

Mechanical Noise (Knock) in Engine .................... 47

Noise Coming from Cylinder ................................. 48

Poor Acceleration or Response ............................ 49

Valve Rotator or Spring Lock Is Free .................... 50

Troubleshooting with a Diagnostic Code

Flash Codes .......................................................... 51

Diagnostic Codes .................................................. 51

Diagnostic Code Cross Reference ....................... 52

CID 0001 FMI 11 ................................................... 54

CID 0002 FMI 11 ................................................... 55

CID 0041 FMI 03 .................................................. 56

CID 0041 FMI 04 .................................................. 57

CID 0091 FMI 08 .................................................. 57

CID 0100 FMI 03 .................................................. 57

CID 0100 FMI 04 .................................................. 57

CID 0110 FMI 03 ................................................... 58

CID 0110 FMI 04 ................................................... 58

CID 0168 FMI 02 .................................................. 58

CID 0172 FMI 03 .................................................. 59

CID 0172 FMI 04 .................................................. 59

CID 0174 FMI 03 .................................................. 59

CID 0174 FMI 04 .................................................. 59

CID 0190 FMI 02 .................................................. 60

CID 0190 FMI 09 .................................................. 60

CID 0190 FMI 11 ................................................... 60

CID 0190 FMI 12 .................................................. 61

CID 0247 FMI 09 .................................................. 61

CID 0248 FMI 09 .................................................. 61

CID 0253 FMI 02 .................................................. 61

CID 0254 FMI 12 .................................................. 62

CID 0261 FMI 13 .................................................. 62

CID 0262 FMI 03 .................................................. 62

CID 0262 FMI 04 .................................................. 63

CID 0268 FMI 02 .................................................. 63

CID 0273 FMI 03 .................................................. 63

CID 0273 FMI 04 .................................................. 63

CID 0274 FMI 03 .................................................. 64

CID 0274 FMI 04 .................................................. 64

CID 0342 FMI 02 .................................................. 64

CID 0342 FMI 11 ................................................... 65

CID 0342 FMI 12 .................................................. 65

CID 0799 FMI 12 .................................................. 65

CID 1690 FMI 08 .................................................. 66

Troubleshooting with an Event Code

Event Codes ........................................................ 67

E162 High Boost Pressure ................................... 69

E360 Low Engine Oil Pressure ............................. 70

E361 High Engine Coolant Temperature .............. 71

E362 Engine Overspeed ....................................... 72

E363 High Fuel Supply Temperature .................... 72

E368 High Intake Manifold Air Temperature ......... 73

Diagnostic Functional Tests

5 Volt Engine Pressure Sensor Supply Circuit -

Test ..................................................................... 75

CAN Data Link Circuit - Test ................................. 81

Data Link Circuit - Test .......................................... 85

ECM Memory - Test .............................................. 88

Electrical Connectors - Inspect ............................. 90

Electrical Power Supply Circuit - Test ................... 94

Engine Pressure Sensor Open or Short Circuit -

Test ..................................................................... 97

Engine Speed/Timing Sensor Circuit - Test ........ 103

Engine Temperature Sensor Open or Short Circuit -

Test .................................................................... 110

Indicator Lamp Circuit - Test ................................ 115

Injector Solenoid Circuit - Test ............................. 119

Speed Control (Analog) - Test ............................ 126

This document has been printed from SPI². Not for Resale

![]() 4

4

Table of Contents

KENR6224

Speed Control (PWM) - Test ............................... 129

Switch Circuits - Test .......................................... 134

Calibration Procedures

Engine Speed/Timing Sensor - Calibrate ............ 138

Index Section

Index ................................................................... 140

This document has been printed from SPI². Not for Resale

![]()

![]() KENR6224

KENR6224

5

Troubleshooting Section

Troubleshoot ing

Section

Ele ct ron ic

Trou bl es hoot ing

System Overview

i02547521

System Operation

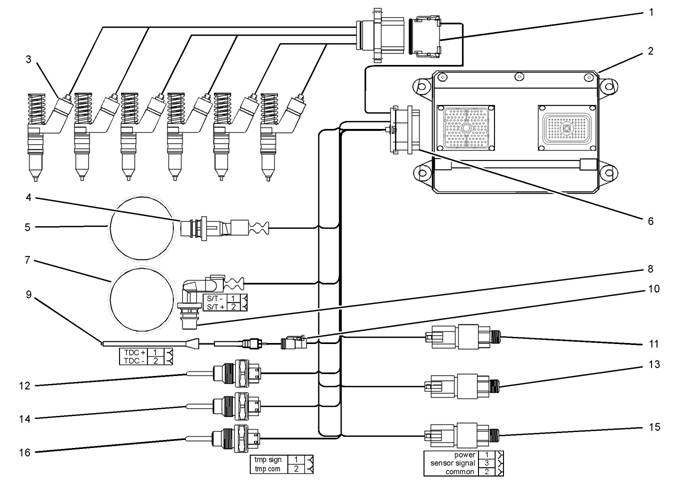

Illustration 1

Block diagram for the 2506-15 engine

(1) 12 Pin Connector

(2) Electronic Control Module (ECM)

(3) Electronic Unit Injectors

(4) Crankshaft Position Sensor

(5) 36 - 1 Tooth Gear

(6) 120 Pin Connector

(7) 36 + 1 Tooth Gear

(8) Camshaft Position Sensor

(9) Timing Calibration Probe

(10) Timing Calibration Probe Connector

(11) Atmospheric Pressure Sensor

(12) Inlet Manifold Temperature Sensor

g01277565

(13) Inlet Manifold Pressure Sensor

(14) Coolant Temperature Sensor

(15) Engine Oil Pressure Sensor

(16) Fuel Temperature Sensor

This engine is electronically controlled. Each cylinder

has an electronic unit injector. The Electronic Control

Module (ECM) sends a signal to each injector

solenoid in order to control the operation of the fuel

injection system.

This document has been printed from SPI². Not for Resale

![]() 6

6

Troubleshooting Section

KENR6224

Electronic Cont rols

The electronic system consists of the following

components: the ECM, the Mechanically Actuated

Electronically Controlled Unit Injectors (MEUI), the

wiring harness, the switches, and the sensors. The

ECM is the computer. The flash file is the software

for the computer. The flash file contains the operating

maps. The operating maps define the following

characteristics of the engine:

• Horsepower

• Torque curves

The ECM determines the timing and the amount of

fuel that is delivered to the cy linders. These decisions

are based on the ac tual conditions and/or on the

desired conditions at any given time.

The ECM compares the desired engine speed to

the actual engine speed. The actual engine speed is

determined through the engine speed/timing sensor.

The desired engine speed is determined with the

following factors:

• Throttle signal

• Other input signals from sensors

• Certain diagnostic codes

If the desired engine speed is greater than the actual

engine speed, the ECM injects more fuel in order to

increase the actual engine speed.

Fuel Injection

The ECM controls the amount of fuel that is injected

by varying the signals to the injectors. The injector will

pump fuel only if the injector solenoid is energized.

The ECM sends a high voltage signal to the solenoid.

This high voltage signal energizes the solenoid. By

controlling the timing and the duration of the high

voltage signal, the ECM can c ontrol injection timing

and the ECM can control the amount of fuel that is

injected.

The ECM limits engine power during cold mode

operation and the ECM modifies injection timing

during cold mode operation. Cold mode operation

provides the following benefits:

• Increased cold weather starting capability

• Reduced warm-up time

• Reduced white smoke

Cold mode is activated whenever the engine

temperature falls below a predetermined value. Cold

mode remains active until the engine temperature

rises above a predetermined value or until a time

limit is exceeded.

The flash file inside the ECM sets certain limits on

the amount of fuel that can be injected. The “FRC

Fuel Limit” is used to control the air/fuel ratio for

control of emissions. The “FRC Fuel Limit” is a limit

that is based on the turbocharger outlet pressure.

A higher turbocharger outlet pressure indicates that

there is more air in the cylinder. When the ECM

senses a higher turbocharger outlet pressure, the

ECM increases the “FRC Fuel Limit”. When the ECM

increases the “FRC Fuel Limit”, the ECM allows

more fuel into the cylinder. The “FRC Fuel Limit” is

programmed into the ECM at the factory. The “FRC

Fuel Limit” cannot be changed.

The “Rated Fuel Limit” is a limit that is based on the

power rating of the engine and on engine rpm. The

“Rated Fuel Limit” is similar to the rack stops and to

the torque spring on a mechanically governed engine.

The “Rated Fuel Limit” provides the power curves

and the torque curves for a specific engine family and

for a spec ific engine rating. The “Rated Fuel Limit” is

programmed into the ECM at the factory. The “Rated

Fuel Limit” cannot be changed.

Once the ECM determines the amount of fuel that

is required, the ECM must determine the timing of

the fuel injection. The ECM uses the signal from the

camshaft position sensor to c alculate the top center

pos ition of eac h cylinder . The ECM decides when

fuel injection should occur relative to the top center

pos ition and the ECM provides the signal to the

injector at the desired time. The ECM adjusts timing

for optimum engine performance, for optimum fuel

economy, and for optimum control of white smoke.

Programmable Parameters

Certain parameters that affect the engine operation

may be changed with the Perkins Electronic

Service Tool (EST). The parameters are stored

in the ECM, and some parameters are protected

from unauthorized changes by passwords. These

pas swords are c alled factory passwords.

Passwords

Several system configuration parameters and most

logged events are protected by factory passwords .

Factory passwords are available only to Perkins

dealers and distributors. Refer to Troubleshooting,

“Factory Passwords” for additional information.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

7

Troubleshooting Section

i02554801

Crankshaft Position Sensor

– This sensor

Glossary

Active Diagnostic Code

– An active diagnostic

determines the position of the crankshaft during

engine operation. If the crankshaft position sensor

fails during engine operation, the camshaft position

sensor is used to provide the signal.

Data Link – The Data Link is a serial communication

code alerts the operator or the service technician that

an electronic system malfunction is currently present.

Refer to the term “Diagnostic Code” in this glossary.

Adaptive Trim – This is a software process that is

performed in the Electronic Control Module (ECM)

that optimizes engine performance.

Alternating Current (AC) – Alternating current is an

electric current that reverses direction at a regular

interval that is reoccurring.

Before Top Center (BTC) – BTC is the 180 degrees

of crankshaft rotation before the piston reaches the

top dead center position in the normal direction of

rotation.

Breakout Harness – A breakout harness is a

test harness that is designed to connect into the

engine harness. This connection allows a normal

circuit operation and the connection simultaneously

provides a Breakout T in order to measure the

signals.

Bypass Circuit – A bypass circuit is a circuit that is

used as a substitute circuit for an existing circuit. A

bypass circ uit is typically used as a test circuit.

Camshaft Position Sensor – This sensor

determines the position of the camshaft during

engine operation. If the crankshaft position sensor

fails during engine operation, the camshaft position

sensor is used to provide the signal.

CAN Data Link (see also J1939 CAN Data Link) –

The CAN Data Link is a serial communications

port that is used for communication with other

microprocessor based devices.

Code – Refer to “Diagnostic Code” or “Event Code”.

Communication Adapter Tool – The

communication adapter provides a communication

link between the ECM and the electronic service tool.

Component Identifier (CID) – The CID is a number

that identifies the specific component of the electronic

control system that has experienced a diagnostic

code.

Coolant Temperature Sensor – The coolant

temperature sensor detects the engine coolant

temperature for all normal operating conditions and

for engine monitoring.

port that is used for communication with other devices

such as the electronic service tool.

Derate – Certain engine conditions will generate

event codes. Also, engine derates may be applied.

The map for the engine derate is programmed into

the ECM software. The derate can be one or more of

3 types: reduction of rated power, reduction of rated

engine speed, and reduction of rated machine speed

for OEM products.

Desired Engine Speed – The desired engine speed

is input to the electronic governor within the ECM.

The electronic governor uses the signal from the

throttle position sensor, the engine speed/timing

sensor, and other sensors in order to determine the

desired engine speed.

Diagnostic Code – A diagnostic code is sometimes

referred to as a fault code. These codes indicate an

electronic system malfunction.

Diagnostic Lamp – A diagnostic lamp is sometimes

called the check engine light. The diagnostic lamp

is used to warn the operator of the presence of

an active diagnostic code. The lamp may not be

included in all applications.

Digital Sensor Return – The common line (ground)

from the ECM is used as ground for the digital

sensors.

Digital Sensors – Digital sensors produce a pulse

width modulated signal. Digital sensors are supplied

with power from the ECM.

Digital Sensor Supply – The power supply for the

digital s ensors is provided by the ECM.

Direct Current (DC) – Direct current is the type of

current that flows consistently in only one direction.

DT, DT Connector, or Deutsch DT – This is a type

of connector that is used on Perkins engines. The

connectors are manufactured by Deutsch.

Duty Cycle – Refer to “Pulse Width Modulation”.

Electronic Engine Control – The electronic

engine control is a complete electronic system.

The electronic engine control monitors the engine

operation under all conditions. The electronic engine

control also controls the engine operation under all

conditions.

This document has been printed from SPI². Not for Resale

![]() 8

8

Troubleshooting Section

KENR6224

Electronic Control Module (ECM) – The ECM

7

– The mechanic al system is not responding

is the control computer of the engine. The ECM

provides power to the electronics. The ECM monitors

data that is input from the sensors of the engine. The

ECM acts as a governor in order to control the speed

and the power of the engine.

Electronic Service Tool – The electronic service

tool allows a computer (PC) to communicate with the

ECM.

Engine Monitoring – Engine Monitoring is the part

of the electronic engine control that monitors the

sensors. This also warns the operator of detected

faults.

Engine Oil Pressure Sensor – The engine oil

pressure sensor measures engine oil pressure. The

sensor sends a signal to the ECM that is dependent

on the engine oil pressure.

Engine Position Sensor – An engine position

sensor is a hall effect switc h that provides a digital

signal to the ECM. The ECM interprets this signal as

the crankshaft position and the engine speed. Two

sensors are used to provide the speed and timing

signals to the ECM. The crankshaft position sensor

is associated with the crankshaft and the camshaft

position sensor is associated with the camshaft.

Event Code – An event code may be activated

in order to indicate an abnormal engine operating

condition. These codes usually indicate a mechanical

fault instead of an electrical system fault.

Failure Mode Identifier (FMI) – This identifier

indicates the type of failure that is associated with

the component. The FMI has been adopted from the

SAE practice of J1587 diagnostics. The FMI follows

the parameter identifier (PID) in the descriptions of

the fault code. The descriptions of the FMIs are in

the following list.

0 – The data is valid but the data is above the normal

operational range.

1 – The data is valid but the data is below the normal

operational range.

2 – The data is erratic, intermittent, or incorrect.

3 – The voltage is above normal or the voltage is

shorted high.

4 – The voltage is below normal or the voltage is

shorted low.

5 – The current is below normal or the circuit is open.

6 – The current is above normal or the circuit is

grounded.

properly.

8 – There is an abnormal frequency, an abnormal

pulse width, or an abnormal time period.

9 – There has been an abnormal update.

10 – There is an abnormal rate of change.

11 – The failure mode is not identifiable.

12 – The device or the component is damaged.

Flash File – This file is software that is inside

the ECM. The file contains all the instructions

(software) for the ECM and the file contains the

performance maps for a specific engine. The file may

be reprogrammed through flash programming.

Flash Programming – Flash programming is the

method of programming or updating an ECM with

an electronic servic e tool over the data link instead

of replacing components.

Fuel Injector E-Trim – Fuel injector E-trim is a

software process that allows precise control of fuel

injectors by parameters that are programmed into

the ECM for eac h fuel injector. With the use of the

electronic service tool, the service technician can

read status information for the E-Trim. Data for

E-Trim can also be programmed.

FRC – See “Fuel Ratio Control”.

Fuel Ratio Control (FRC) – The FRC is a limit that

is based on the control of the ratio of the fuel to air.

The FRC is used for purposes of emission control.

When the ECM senses a higher intake manifold

air pressure (more air into the cylinder), the FRC

increases the FRC Limit (more fuel into the cylinder).

Full Load Setting (FLS) – The FLS is the parameter

that represents the fuel system adjustment. This

adjustment is made at the factory in order to fine tune

the fuel system. The correct value for this parameter

is stamped on the engine information ratings plate.

This parameter must be programmed.

Full Torque Setting (FTS) – The FTS is the

parameter that represents the adjustment for the

engine torque. This adjustment is made at the factory

in order to fine tune the fuel system. This adjustment

is made in conjunction with the FLS. This parameter

must be programmed.

Harness – The harness is the bundle of wiring

(loom) that connects all components of the electronic

system.

This document has been printed from SPI². Not for Resale

![]()

![]() KENR6224

KENR6224

9

Troubleshooting Section

Hertz (Hz)

– Hertz is the measure of electrical

Password – A password is a group of numeric

frequency in cycles per second.

Injector Codes – The injector codes or injector trim

codes are numeric codes or alphanumeric codes

that are etched or stamped on individual electronic

unit injectors. These codes are used to fine tune the

fuel delivery.

Injector Trim Files – Injector trim files are

downloaded from a disk to the ECM. The injector

trim files compensate for variances in manufacturing

of the electronic unit injector and for the life of the

electronic unit injector. The serial number for the

electronic unit injector must be obtained in order to

retrieve the correct injector trim file.

Intake Manifold Air Temperature Sensor – The

intake manifold air temperature sensor detec ts the

air temperature in the intake manifold. The ECM

monitors the air temperature and other data in the

intake manifold in order to adjust injection timing and

other performance functions .

Intake Manifold Pressure Sensor – The Intak e

Manifold Pressure Sensor measures the pressure

in the intake manifold. The pressure in the intake

manifold may be different to the pressure outside

the engine (atmospheric pressure). The difference

in pressure may be caused by an increase in air

pressure by a turbocharger (if equipped).

Integrated Electronic Controls – The engine is

designed with the electronic controls as a necessary

part of the system. The engine will not operate

without the electronic controls.

J1939 CAN Data Link – This data link is a SAE

standard diagnostic c ommunications data link that

is used to communicate between the ECM and the

electronic dev ices.

Logged Diagnostic Codes – Logged diagnostic

codes are codes which are stored in the memory.

These codes are meant to be an indicator of

possible causes for intermittent faults. Refer to the

term “Diagnostic Code” in this glossary for more

information.

OEM – OEM is an abbreviation for the Original

Equipment Manufacturer. This is the manufacturer of

the machine or the vehicle that uses the engine.

Open Circuit – An open circuit is a condition that is

caused by an open switch, or by an elec trical wire

or a connection that is broken. When this condition

exists, the signal or the supply voltage can no longer

reach the intended destination.

Parameter – A parameter is a value or a limit that

is programmable. This helps determine specific

characteristics or behaviors of the engine.

|

that is designed to restrict acc ess to parameters. The

electronic system requires correct passwords in order

to change some parameters (Factory Passwords).

Refer to Troubleshooting, “Factory Passwords” for

more information.

Personality Module – See “Flash File”.

Power Cycled – Power cycled happens when power

to the ECM is cycled: ON, OFF, and ON. Power

cycled refers to the action of cycling the k eyswitch

from any position to the OFF position, and to the

START/RUN position.

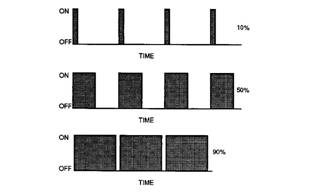

Pulse Width Modulation (PWM) – The PWM is a

signal that consists of pulses that are of variable

width. These pulses occur at fixed intervals. The ratio

of “TIME ON” versus total “TIME OFF” c an be varied.

This ratio is also referred to as a duty cycle.

Illustration 2

Rated Fuel Limit – This is a limit that is based on

the power rating of the engine and on the engine rpm.

The Rated Fuel Limit enables the engine power and

torque outputs to conform to the power and torque

curves of a specific engine model. These limits are in

the flash file and these limits cannot be changed.

Reference Voltage – Reference voltage is a

regulated voltage and a steady voltage that is

supplied by the ECM to a sensor. The reference

voltage is used by the sensor to generate a signal

voltage.

Relay – A relay is an electromec hanical switc h. A

flow of electricity in one circuit is used to control the

flow of electricity in another circuit. A small current or

voltage is applied to a relay in order to switch a much

larger current or voltage.

Sensor – A sens or is a device that is used to

detect the current value of pressure or temperature,

or mechanical movement. The information that is

detected is converted into an electrical signal.

This document has been printed from SPI². Not for Resale

| |||||||||||||||||||||||||||

Troubleshooting Section

KENR6224

Short Circuit – A short circuit is a condition that has

an electrical circuit that is inadvertently connected to

an undesirable point. An example of a short circuit

is a wire which rubs against a vehicle frame and

this rubbing eventually wears off the wire insulation.

Electrical contact with the frame is made and a s hort

circuit results.

Signal – The signal is a voltage or a waveform that

is used in order to transmit information ty pically from

a sensor to the ECM.

•

•

•

•

•

Obtain data.

Diagnose faults.

Read parameters.

Program parameters.

Calibrate sensors.

Supply Voltage – The supply voltage is a continuous

voltage that is supplied to a component in order to

provide the elec trical power that is required for the

component to operate. The power may be generated

by the ECM or the power may be battery voltage that

is supplied by the engine wiring.

System Configuration Parameters – System

configuration parameters are parameters that affect

emiss ions and/or operating charac teristics of the

engine.

Tattletale – Certain parameters that affect the

operation of the engine are stored in the ECM.

These parameters can be changed by use of the

electronic service tool. The tattletale logs the number

of changes that have been made to the parameter.

The tattletale is stored in the ECM.

Throttle Position – The throttle position is the

interpretation by the ECM of the signal from the

throttle position sensor or the throttle switch.

Timing Calibration – The timing calibration is the

adjustment of an electrical signal. This adjustment is

made in order to correct the timing error between the

camshaft and the engine speed/timing sensors or

between the crankshaft and the engine speed/timing

sensors.

Top Center Position – The top center position refers

to the crankshaft position when the engine piston

position is at the highest point of travel. The engine

must be turned in the normal direction of rotation in

order to reach this point.

Total Tattletale – The total tattletale is the total

number of changes to all the parameters that are

stored in the ECM.

i02547729

Electronic Service Tools

Perkins Electronic Service Tools are designed to help

the service technician:

Required Service Tools

The tools that are listed in Table 1 are required in

order to enable a service technician to perform the

procedures.

Table 1

Two short jumper wires are needed to check the

continuity of some wiring harness circuits by shorting

two adjacent terminals together in a connector. A

long extension wire may also be needed to check the

continuity of some wiring harness circuits.

Perkins Electronic Service Tool

(EST)

The Perkins EST can display the following

information:

• Parameters

• Event codes

• Diagnostic codes

• Engine configuration

This document has been printed from SPI². Not for Resale

![]()

![]()

![]() KENR6224

KENR6224

11

Troubleshooting Section

The Perkins EST can be used by the technician to

perform the following functions:

• Diagnostic tests

• Sensor calibration

• Flash programming

• Set parameters

Table 2 lists the service tools that are required in

order to use Perkins EST.

Table 2

Connecting Perkins EST and the

Communication Adapter II

|

Service Tools for the Use of Perkins EST | |

|

Part Number |

Description |

|

-(1) |

Personal Computer (PC) |

|

-(1) |

<, TD vAlign=top width=231>

|

|

-(1) |

Data Subscription for All Engines |

|

27610251 |

Communi cation Adapter Gp |

|

27610164(2) |

Adapter Cable As |

(1)

(2)

Refer to the Perkins Engine Company Limited.

The 27610164 Adapter Cable As is required to connect to the

USB port on computers that are not equipped with a RS232

serial port.

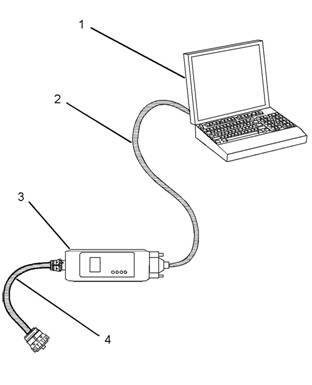

Illustration 3

(1) Personal computer (PC)

g01115382

Note: For more information regarding the use of

Perkins EST and the PC requirements for Perkins

EST, refer to the documentation that accompanies

your Perkins EST software.

(2) Adapter Cable (RS232 Port)

(3) Communication Adapter As

(4) Adapter Cable As

Note: Items (2), (3), and (4) are part of the 27610251

Communication Adapter Gp.

Use the following procedure in order to c onnect

Perkins EST and the Communication Adapter II.

1. Turn the keyswitch to the OFF position. If the

keyswitch is not in the OFF position, the engine

may start.

2. Connect cable (2) between the “COMPUTER”

end of communication adapter (3) and the RS232

serial port of PC (1).

Note: An adapter cable assembly is required to

connect to the USB port on computers that are not

equipped with a RS232 serial port.

3. Connect cable (4) between the “DATA LINK” end

of communication adapter (3) and the diagnostic

connector.

This document has been printed from SPI². Not for Resale