產(chǎn)品中心

美國強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國麥克福斯

卡特彼勒柴油發(fā)動機(jī)參數(shù)

沃爾沃發(fā)動機(jī)全系參數(shù)

英國珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動機(jī)零件查詢圖冊

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國道依茨 韓國大宇柴油發(fā)動機(jī)配件

康明斯全系列柴油發(fā)動機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動機(jī)配件中心

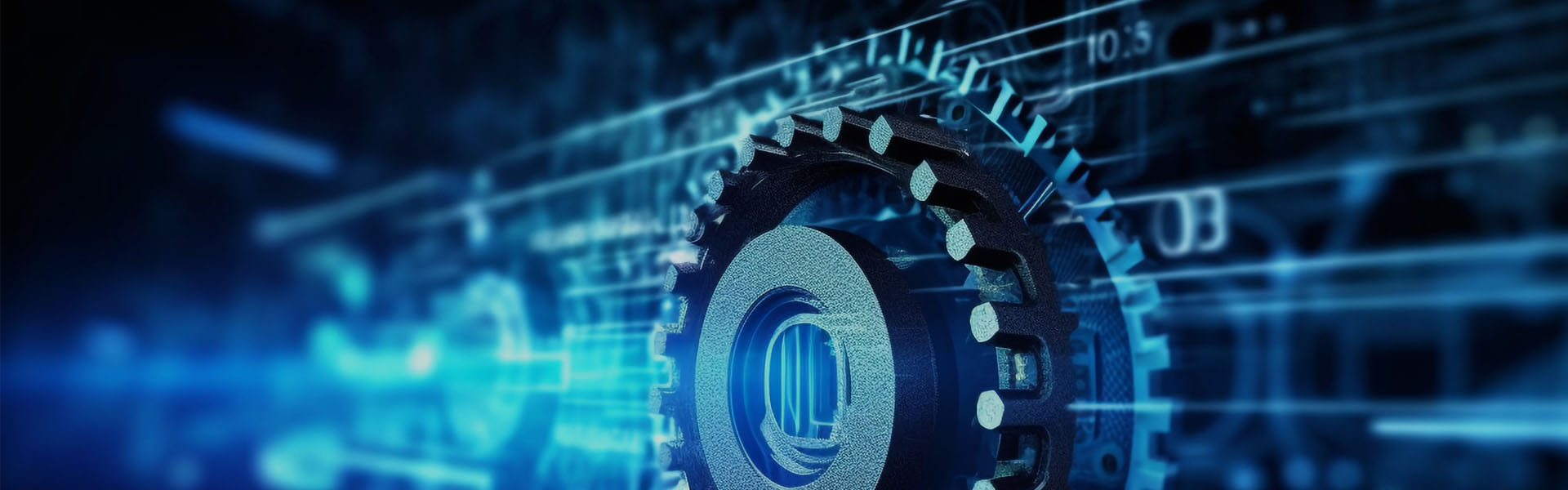

Perkins2506柴油發(fā)動機(jī)威爾遜P500E柴油發(fā)電機(jī)配件汽缸蓋墊

詳細(xì)描述

項目 零配件號碼 新件號 描述

1 CH11399 1 CH11399 汽缸蓋組合

1 CH11399 1 CH11399 汽缸蓋組合

(1) CH11399 1 CH11399 汽缸蓋裝備 -EXCH

(1) CH11399 1 CH11399 汽缸蓋裝備 -EXCH

項目 零配件號碼 新件號 描述

1 1 密封墊 - 汽缸蓋

2 CH10712 16 CH10712 螺拴

3 CH10711 16 CH10711 墊圈

4 CH10713 10 CH10713 螺拴

5 CH10711 10 CH10711 墊圈

6 CH10708 6 CH10708 套筒

7 CH10286 3 CH10286 栓塞

8 CH10133 3 CH10133 密封O型圈

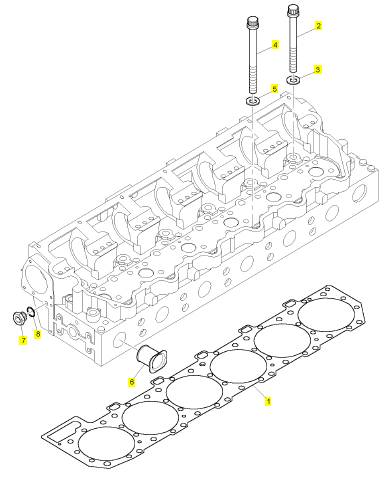

項目 零配件號碼 新件號 描述

1 CH11526 1 CH11526 惰輪傳動機(jī)構(gòu)

1 CH10963 1 CH10963 惰輪傳動機(jī)構(gòu)

2 CH10876 1 CH10876 螺木樁

3 CH10611 5 CH10611 螺拴

4 CH10619 1 CH10619 推力板

5 CH10621 4 CH10621 螺拴

6 CH10622 1 CH10622 油泵傳動機(jī)構(gòu)

7 CH10005 1 CH10005 半圓鍵

8 CH10609 1 CH10609 螺拴

9 CH10610 1 CH10610 墊圈

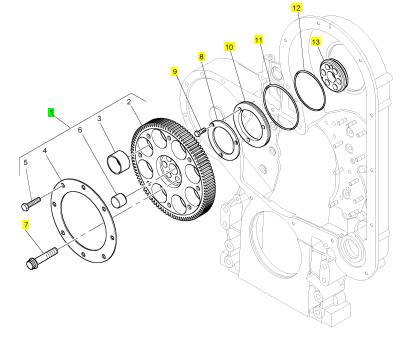

項目 零配件號碼 新件號 描述

1 T400235 1 T400235 凸輪軸傳動機(jī)構(gòu)

1 CH10910 1 T400235 凸輪軸傳動機(jī)構(gòu)

7 CH10616 6 CH10616 螺拴

8 CH10617 1 CH10617 推力板

9 CH10618 3 CH10618 螺拴

10 CH10625 1 CH10625 密封墊

11 CH10620 1 CH10620 密封O型圈

12 CH10612 1 CH10612 密封O型圈

13 CH10627 1 CH10627 承接器

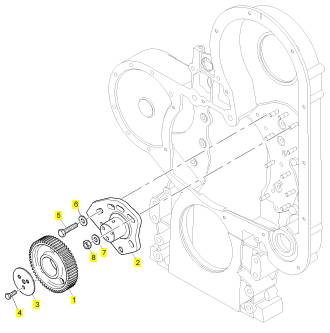

項目 零配件號碼 新件號 描述

1 CH10635 1 CH10635 惰輪傳動機(jī)構(gòu)

2 CH10623 1 CH10623 螺木樁

3 CH10614 1 CH10614 推力板

4 CH10621 3 CH10621 螺拴

5 CH10609 1 CH10609 螺拴

6 CH10615 1 CH10615 墊圈

7 CH10615 5 CH10615 墊圈

8 CH10290 5 CH10798 螺帽

項目 零配件號碼 新件號 描述

1 CH10632 1 CH10632 惰輪傳動機(jī)構(gòu)

2 CH10624 1 CH10624 螺木樁

3 CH10290 5 CH10798 螺帽

4 CH10615 5 CH10615 墊圈

5 CH10609 1 CH10609 螺拴

6 CH10615 1 CH10615 墊圈

7 CH10614 1 CH10614 推力板

8 CH10621 3 CH10621 螺拴

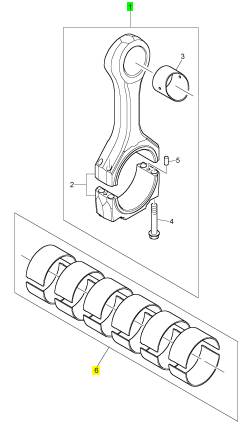

項目 零配件號碼 新件號 描述

1 CH11507 6 CH11507 連桿組合

6 KRP3016 1 KRP3016 大頭軸承裝備

(6) KRP3016/064 1 KRP3016/064 大頭 BRG 裝備 -U/S

(6) KRP3016/127 1 KRP3016/127 大頭 BRG 裝備 -U/S

Note: If the flywheel is turned beyond the point

of engagement, the flywheel must be turned in

the opposite direction of normal engine rotation

approximately 45 degrees. Then turn the flywheel in

the direction of normal rotation until the timing bolt

engages with the threaded hole. The procedure will

eliminate the backlash that will occur when the No. 1

piston is put on the top center.

3. Remove the front valve mechanism cover from

the engine.

4. The inlet and exhaust valves for the No. 1 cylinder

are fully closed if the No. 1 piston is on the

compression stroke and the rocker arms can be

moved by hand. If the roc ker arms can not be

moved and the valves are slightly open the No. 1

pis ton is on the exhaust stroke.

Note: After the actual stroke position is identified,

and the other s troke position is needed, remove the

timing bolt from the flywheel. The flywheel is turned

360 degrees in a counterclockwise direction. The

3.

Refer to Operation and Maintenance Manual,

“Fuel Recommendations” for more information.

If fuel quality is still suspected as a possible

cause to problems regarding engine performance,

dis connect the fuel inlet line, and temporarily

operate the engine from a separate source of

fuel that is known to be good. This will determine

if the problem is caused by fuel quality. If fuel

quality is determined to be the problem, drain the

fuel system and replace the fuel filters. Engine

performance can be affected by the following

characteristics:

• Cetane number of the fuel

• Air in the fuel

• Other fuel characteristics

i02551471

timing bolt is reinstalled.

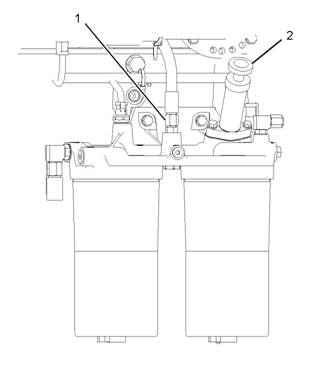

Fuel System - Prime

Fuel Quality - Test

i02551477

NOTICE

Use a suitable container to c atch any fuel that might

spill. Clean up any spilled fuel immediately.

Ensure that all adjustments and repairs are performed

by authorized personnel that have had the correct

training.

Use the following procedure to test for problems

regarding fuel quality:

1. Determine if water and/or contaminants are

present in the fuel. Check the water separator (if

equipped). If a water separator is not present,

proceed to Step 2. Drain the water separator, if

neces sary. A full fuel tank minimizes the potential

for overnight condensation.

Note: A water separator can appear to be full of fuel

when the water separator is actually full of water.

2. Determine if contaminants are present in the

fuel. Remove a sample of fuel from the bottom

of the fuel tank. Visually inspect the fuel sample

for contaminants. The color of the fuel is not

necessarily an indication of fuel quality. However,

fuel that is black, brown, and/or similar to sludge

can be an indication of the growth of bacteria or

oil contamination. In cold temperatures, cloudy

fuel indicates that the fuel may not be suitable for

operating conditions.

NOTICE

Do not allow dirt to enter the fuel system. Thoroughly

clean the area around a fuel system component that

will be disconnected. Fit a suitable cover over discon-

nec ted fuel system component.

Note: This procedure is most common when the

engine has run out of fuel.

1. Turn the ignition switch to the “OFF” position.

2. Fill the fuel tank(s) with clean diesel fuel.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]() KENR6231

KENR6231

27

Testing and Adjusting Section

•

The engine starts, but the engine continues to

misfire or smoke.

9.

Run the engine with no load until the engine runs

smoothly.

i02571703

Fuel System Pressure - Test

Illustration 25

Typical example

g01282239

|

|

Low fuel pressure can cause low power. Low fuel

pressure can also cause cavitation of the fuel

which can damage the fuel injectors. The following

conditions can cause low fuel pressure:

• Plugged fuel filters

pump

• Debris in the pressure regulating valve

• Partially open check valve

the fuel transfer pump

3.

Loosen the union of the pipe for the fuel(1).

•

Severe wear on return fuel pressure regulating

valve in the fuel filter base

Note: Do not remove the union completely. Open the

union enough to allow the air that is trapped in the

cylinder head to be purged from the fuel system.

4. Unlock and operate the hand priming pump (2).

Use a suitable container to collect excess fuel.

5. Tighten the union of the pipe for the fuel (1).

6. Operate the hand priming pump until a strong

pressure is felt on the pump. Push the priming

pump plunger inward. Tighten the plunger by hand

and s tart the engine.

NOTICE

Do not crank the engine continuously for more than

30 seconds. Allow the starting motor to cool for 30

•

•

•

•

•

•

Worn gears in the fuel transfer pump

Pinched fuel lines or undersized fuel lines

Old fuel lines that have a reduced interior diameter

that was caused by swelling

Fuel lines with deteriorating interior surfaces

Pinched fuel line fittings or undersized fuel line

fittings

Debris in the fuel tank, fuel lines, or fuel system

components that create restrictions

|

7. If the engine will not start, allow the starting motor

to cool for 30 seconds. Repeat steps 3 to 6 in

order to operate the engine.

8. Continue to eliminate air from the fuel system if

these events occ ur:

evenly.

High Fuel Pressure

Excessive fuel pressure can cause fuel filter gaskets

to rupture. The following conditions can cause high

fuel pressure:

• Plugged orifices in the fuel pressure regulating

valve

• Stuck fuel pressure regulating valve in the fuel

transfer pump

• Pinched fuel return line

This document has been printed from SPI². Not for Resale

![]() 28

28

Testing and Adjusting Section

KENR6231

Checking Fuel Pressure

Table 6

Gear Group (Front) - Time

i02551488

Tool

A

Required Tools

Part Number Part Description

- Pressure Gauge

Qty

1

Illustration 26

g01288627

To check the fuel transfer pump pressure, remove

the hose assembly (1). Install a pressure gauge, and

start the engine.

Fuel Pressure Readings

The typical fuel pressure of the engine at operating

temperature c an vary. When the engine is under

load, the fuel pressure can be 550 kPa (80 psi).

The performance of the unit injector deteriorates

when the fuel pressure drops below 241 kPa (35 psi).

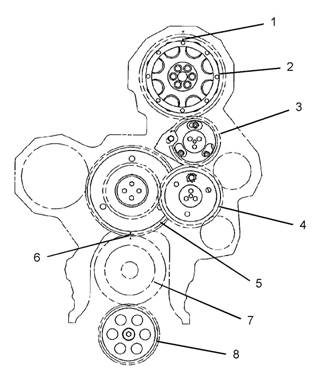

Illustration 27

Front gear group

(1) Timing marks

(2) Camshaft gear

(3) Adjustable idler gear

(4) Idler gear

(5) Cluster gear

(6) Timing marks

(7) Crankshaft gear

(8) Oil pump gear

g01097754

Low power complaints and erratic operation can

occur in this situation. Check for a plugged fuel filter

or air in the fuel lines as possible causes for these

complaints before replacing fuel system components.

The basis for the correct fuel injection timing and

the v alve mechanism operation is determined by

the alignment of the timing for the front gear group.

Timing marks (1) through timing marks (6) are aligned

in order to provide the c orrect relationship between

the piston movement and the valve movement.

This document has been printed from SPI². Not for Resale

| |||||||||||||||||||||

29

Testing and Adjusting Section

Setting

Backlash

For Camshaft

And Adjustable Idler Gear

Table 7

B

1.

Remove the front cover. Refer to Disassembly and

Assembly, “Housing (front) - Remove”.

Note: Ensure that No. 1 pis ton is at the top center

position. Refer to Systems Operation, Testing and

Adjusting, “Finding Top Center Position for No. 1

Piston”.

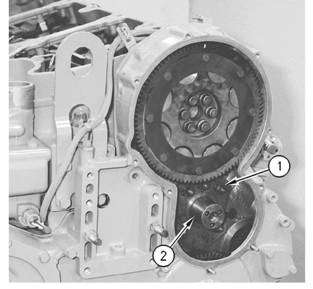

Illustration 29

Typical example

Installation of the adjustable idler assembly

(A) Cams haft Alignment tool

(1) Nuts

(3) Bolt

g00294873

3.

Refer to Illustration 29 in order to position Tooling

(A). Move Tooling (A) to the left and to the right.

Lightly tighten nuts (1) and bolt (3). Once the nuts

and the bolt are tightened, lightly tap Tooling (A)

with a rubber mallet on the sides. This will ensure

that the tool is properly seated. Tooling (A) should

be free to move in and out without any binding.

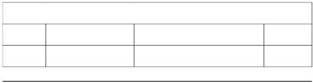

Illustration 28

Typical example

Loosen stub shaft assembly.

(1) Nuts

(2) Stub shaft

g00294872

2.

Remove the adjus table idler gear from stub shaft

(2). Stub shaft (2) is held in position with five nuts

(1) and one bolt. Loosen five nuts (1) and loosen

the one bolt.

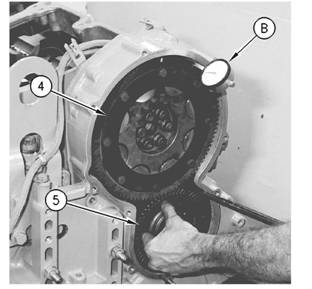

Illustration 30

Typical example

Checking backlash

(B) Indicator assembly

(4) Camshaft gear

(5) Idler gear assembly

g00294874

This document has been printed from SPI². Not for Resale

![]() 30

30

Testing and Adjusting Section

KENR6231

4.

5.

6.

7.

Install Tooling (B) on the timing gear housing.

Loosely install the idler gear assembly (5) to the

timing gear housing. When idler gear assembly

(5) is held stationary, the bac klash between

the camshaft gear (4) and the idler gear (5) is

0.216 ± 0.114 mm (0.0085 ± 0.0045 inch).

If necessary, repeat step 2 through step 4 in order

to obtain the proper backlash.

Tighten the nuts and the bolt. Refer to Disassembly

and Assembly, “Gear Group (Front) - Install” for

the correct procedure.

Install the front cover. Refer to Disassembly and

Assembly, “Housing (Front) - Install”.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]() KENR6231

KENR6231

31

Testing and Adjusting Section

Air

Inlet

and

Exhaust

Syst em

Air

Inlet and

i02581541

Exhaust System

-

Inspect

A general visual inspection should be made to the air

inlet and exhaust system. Make sure that there are

no signs of leaks in the system.

Table 8

|

Required Tools | |||

|

Tool |

Part Number |

Part Description |

Qty |

|

A |

- |

Differential Pressure Gauge |

1 |

Air Inlet Restriction

There will be a reduction in the performance of the

engine if there is a restriction in the air inlet system.

1. Inspect the engine air cleaner inlet and ducting

in order to ensure that the passageway is not

blocked or collapsed.

2. Inspect the engine air cleaner element. Replace

a dirty engine air cleaner element with a clean

engine air cleaner element.

3. Check for dirt tracks on the clean side of the

engine air cleaner element. If dirt tracks are

observed, contaminants are flowing past the

engine air cleaner element and/or the seal for the

engine air cleaner element.

Hot engine

components

can cause

injury

from

burns.

Before

performing

maintenance

on

the

engine, allow the engine and the components to

cool.

Making contact with a running engine can cause

burns from hot parts and can cause injury from

rotating parts.

When working on an engine that is running, avoid

contact with hot parts and rotating parts.

4. Use Tooling (A) for this test.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]() 32

32

Testing and Adjusting Section

KENR6231

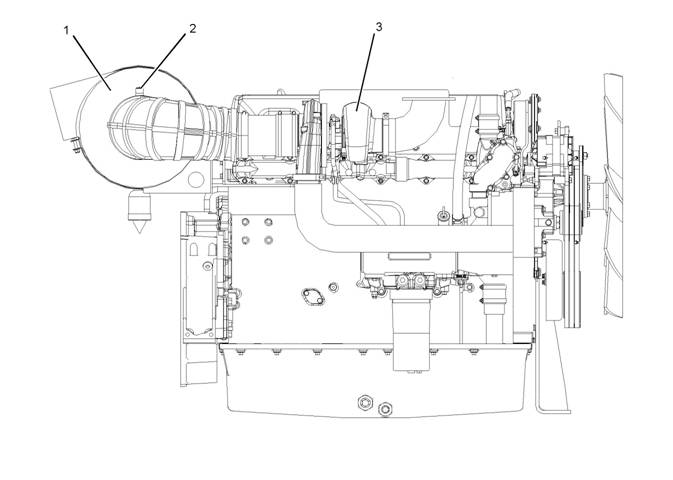

Illustration 31

Air inlet piping

(1) Air Cleaner

(2) Test location

(3) Turbocharger

g01293044

a.

Connect the v acuum port of the differential

pressure gauge to test location (2). Test

location (2) may be located anywhere along the

air inlet piping after air cleaner (1) but before

turbocharger (3).

Maximum restriction ........ 6.2 kPa (25 in of H2O)

The air flow through a new engine air cleaner element

must not have a restriction of more than the following

amount:

Maximum restriction ........ 3.7 kPa (15 in of H2O)

b. Leave the pressure port of the differential

pressure gauge open to the atmosphere.

c. Start the engine. Run the engine at full load.

d. Record the value.

e. Compare the result from step 4.d to the

appropriate values that follow.

The air flow through a used engine air cleaner

may have a restriction. The air flow through a

Turbocharger - Inspect

Hot engine components can cause

i02551491

injury from

plugged engine air cleaner will be restricted to some

burns.

Before

performing

maintenance

on

the

magnitude. In either case, the restriction must not be

more than the following amount:

engine, allow the engine and the components to

cool.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]() KENR6231

KENR6231

33

Testing and Adjusting Section

Personal injury can result from rotating and mov-

ing parts.

Stay clear of all rotating and moving parts.

Never attempt adjustments while the machine is

moving or the engine is running unless otherwise

specified.

The machine must be parked on a level surface

and the engine stopped.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

Dispose of all fluids according to local regulations and

mandates.

Before you begin inspection of the turbocharger,

be sure that the inlet air restriction is within the

specifications for your engine. Be sure that the

exhaust system restriction is within the specifications

for your engine. Refer to Systems Operation, Testing

and Adjusting, “Air Inlet and Exhaust System -

Inspect”.

The condition of the turbocharger will have definite

effects on engine performance. Use the following

inspections and procedures to determine the

condition of the turbocharger.

• Inspection of the Compressor and the Compressor

Housing

• Inspection of the Turbine Wheel and the Turbine

Housing

1.

2.

3.

4.

Inspect the compressor wheel for damage from a

foreign object. If there is damage, determine the

source of the foreign object. As required, clean

the inlet system and repair the intake system.

Replace the turbocharger. If there is no damage,

go to Step 3.

Clean the compressor wheel and clean the

compressor housing if you find buildup of foreign

material. If there is no buildup of foreign material,

go to Step 3.

Turn the rotating assembly by hand. While you

turn the assembly, push the assembly sideways .

The assembly should turn freely. The compressor

wheel should not rub the compress or housing.

Replace the turbocharger if the compressor wheel

rubs the compressor wheel housing. If there is no

rubbing or scraping, go to Step 4.

Inspect the compressor and the compressor

wheel housing for oil leakage. An oil leak from

the compressor may deposit oil in the aftercooler.

Drain and c lean the aftercooler if you find oil in

the aftercooler.

a. Check the oil level in the crankcase. If the oil

level is too high, adjust the oil level.

b. Inspect the air cleaner element for restriction. If

restriction is found, correct the problem.

c. Inspect the engine crankcase breather. Clean

the engine crankcase breather or replace

the engine crankcase breather if the engine

crankc ase breather is plugged.

d. Remove the oil drain line for the turbocharger.

Inspect the drain opening. Inspect the oil drain

line. Inspect the area between the bearings of

the rotating assembly shaft. Look for oil sludge.

Inspect the oil drain hole for oil sludge. Inspect

the oil drain line for oil sludge in the drain

line. If neces sary, clean the rotating assembly

shaft. If necessary, clean the oil drain hole. If

necessary, clean the oil drain line.

e. If Steps 4.a through 4.d did not reveal the

source of the oil leakage, the turbocharger has

internal damage. Replace the turbocharger.

Inspection of the Compressor and

the Compressor Housing

Remove air piping from the compressor inlet.

Inspection of the Turbine Wheel

and the Turbine Housing

Remove the air piping from the turbine housing.

This document has been printed from SPI². Not for Resale

| |||||||||||||

Testing and Adjusting Section

KENR6231

a.

Remove the oil drain line for the turboc harger.

Inspect the drain opening. Inspect the area

between the bearings of the rotating assembly

shaft. Look for oil s ludge. Inspect the oil drain

hole for oil sludge. Inspect the oil drain line

for oil sludge. If necessary, clean the rotating

assembly shaft. If necessary, clean the drain

opening. If necessary, clean the drain line.

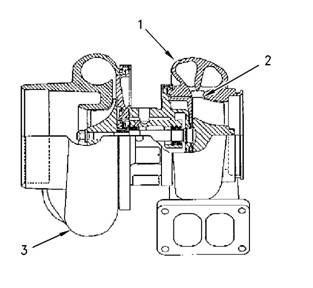

Illustration 32

Typical example

(1) Turbine Housing

(2) Turbine Wheel

(3) Turbocharger

g00763164

b. If crankcase pressure is high, or if the oil drain

is restricted, pressure in the center housing

may be greater than the pressure of turbine

housing (1). Oil flow may be forced in the wrong

direction and the oil may not drain. Check the

crankc ase pressure and correct any problems.

c. If the oil drain line is damaged, replace the oil

drain line.

d. Check the routing of the oil drain line. Eliminate

any sharp restrictive bends. Make sure that

the oil drain line is not too close to the engine

exhaust manifold.

e. If Steps 4.a through 4.d did not reveal the

source of the oil leakage, turbocharger (3) has

internal damage. Replace turbocharger (3).

1.

2.

3.

4.

Inspect the turbine for damage by a foreign object.

If there is damage, determine the source of the

foreign object. Replace turbocharger (3). If there

is no damage, go to Step 2.

Inspect turbine wheel (2) for buildup of carbon and

other foreign material. Inspect turbine housing (1)

for buildup of carbon and foreign material. Clean

turbine wheel (2) and clean turbine housing (1) if

you find buildup of carbon or foreign material. If

there is no buildup of carbon or foreign material,

go to Step 3.

Turn the rotating assembly by hand. While you

turn the assembly, push the assembly sideways.

The assembly should turn freely. Turbine wheel (2)

should not rub turbine wheel housing (1). Replace

turbocharger (3) if turbine wheel (2) rubs turbine

housing (1). If there is no rubbing or scraping, go

to Step 4.

Inspect the turbine and turbine housing (1) for oil

leakage. Inspect the turbine and turbine housing

(1)for oil coking. Some oil coking may be cleaned.

Heavy oil coking may require replacement of

the turbocharger. If the oil is coming from the

turboc harger center housing go to Step 4.a.

Otherwise go to “Inspection of the Wastegate”.

i02571444

Exhaust Temperature - Test

Table 9

When the engine runs, the temperature of an exhaust

manifold port can indicate the condition of a fuel

injection nozzle.

A low temperature indicates that no fuel is flowing to

the cylinder. An inoperative fuel injection nozzle or

a problem with the fuel injection pump could caus e

this low temperature.

A very high temperature can indicate that too much

fuel is flowing to the cylinder. A malfunctioning

fuel injection nozzle could cause this very high

temperature.

Use the Tooling (A) to check exhaust temperature.

This document has been printed from SPI². Not for Resale

![]()

![]()

| |||||||||||||

| ||||||||||||||||

35

Testing and Adjusting Section

Engine

Crankcase

i02571687

Pressure

This engine uses high voltage to control the fuel

(Blowby) - Test

Table 10

Damaged pistons or rings can cause too much

pressure in the crankcase. This condition will cause

the engine to run rough. There will be more than the

normal amount of fumes (blowby) rising from the

crankcase breather. The breather can then become

restricted in a very short time, causing oil leakage

at gaskets and seals that would not normally have

leakage. Blowby can also be caused by worn valve

guides or by a failed turbocharger seal.

Install Tooling (A) to the most convenient location on

the output tube for the crankcase breather or the

breather hose. The pressure for the engine blowby

should be 0.25 kPa (1 inch of H2O).

Note: Do not use the data alone to determine if the

engine should be overhauled. Other indicators such

as high oil consumption, low power, hard starting,

and excessive fuel cons umption must be considered.

After a new engine is used for a short time, the

blowby can decrease as the rings are seated. New

engines should be checked for blowby during all

maintenance checks. As the piston rings and cylinder

walls wear, the blowby will gradually increase.

The blowby on a worn engine may be two times or

more than the blowby of a new engine and may

indicate the need for an overhaul.

injectors.

Disconnect electronic fuel injector enable circuit

connector to prevent personal injury.

Do not come in contact with the fuel injector ter-

minals while the engine is running.

Note: Valve lash is measured between the rock er

arm and the valve bridge. All measurements and

adjustments must be made with the engine stopped

and the valves fully closed.

Valve Lash Check

An adjustment is NOT NECESSARY if the

measurement of the valve lash is in the acceptable

range in Table 11.

Table 11

(1) 360° from TC compression stroke

(2) The No. 1 cylinder is at the front of the engine.

If the measurement is not within this range, an

adjustment is necessary. Refer to “Valve Lash

Adjustment” for the proper procedure.

Engine

Valve

Lash

-

i02553372

Inspect/Adjust

To prevent possible injury, do not use the starter

to turn the flywheel.

Hot engine components can cause burns. Allow

additional time for the engine to cool before mea-

suring valve clearance.

This document has been printed from SPI². Not for Resale

|

|

Testing and Adjusting Section

KENR6231

Valve Lash Adjustment

Note: If necessary, adjust the electronic unit injectors

on cylinders 3, 5 and 6. Refer to Systems Operation,

Testing and Adjusting, “Electronic Unit Injector -

Adjust” for the correct procedure.

3. Remove the timing pin. Turn the flywheel by 360

degrees in the direction of engine rotation. This

will put the No. 6 piston at the top center position

on the compression stroke. Install the timing pin.

Table 13

Illustration 33

Cylinder and valve loc ation

(A) Exhaust valves

(B) Inlet valves

g00935559

4.

Adjust the valve lash according to Table 13.

Use the following procedure to adjust the valve lash:

1. Put the No. 1 piston at the top center position

on the compress ion stroke. Refer to Systems

Operation, Testing and Adjusting, “Finding Top

Center Position for No. 1 Piston”.

a.

Lightly tap the rocker arm with a soft mallet.

This will ensure that the lifter roller seats

against the camshaft’s base circle.

Table 12

2. Adjust the valve lash according to Table 12.

a. Lightly tap the rocker arm with a soft mallet.

This will ensure that the lifter roller seats

agains t the camshaft’s base circle.

b. Loosen the adjustment locknut.

c. Place the appropriate feeler gauge between

5.

b. Loosen the adjustment locknut.

c. Plac e the appropriate feeler gauge between

rocker arm and the valve bridge. Then, turn

the adjustment screw in a cloc kwise direction.

Slide the feeler gauge between the rock er arm

and the valve bridge. Continue turning the

adjustment screw until a slight drag is felt on

the feeler gauge. Remove the feeler gauge.

d. Tighten the adjustment locknut to a torque

of 30 ± 7 N·m (22 ± 5 lb ft). Do not allow

the adjustment screw to turn while you are

tightening the adjustment locknut. Recheck

the valve lash after tightening the adjustment

locknut.

Remove the timing bolt from the flywheel after all

adjustments to the valve lash have been made.

Reinstall the timing cover.

rocker arm and the valve bridge. Then, turn

the adjustment screw in a clockwise direction.

Slide the feeler gauge between the rocker arm

and the valve bridge. Continue turning the

adjustment screw until a slight drag is felt on

the feeler gauge. Remove the feeler gauge.

d. Tighten the adjustment locknut to a torque

of 30 ± 7 N·m (22 ± 5 lb ft). Do not allow

the adjustment screw to turn while you are

tightening the adjustment locknut. Recheck

the valve lash after tightening the adjustment

locknut.

Refer to Systems Operation, Testing and Adjusting,

“Electronic Unit Injector - Adjust”.

This document has been printed from SPI². Not for Resale