產(chǎn)品中心

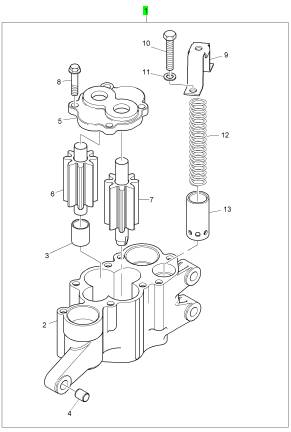

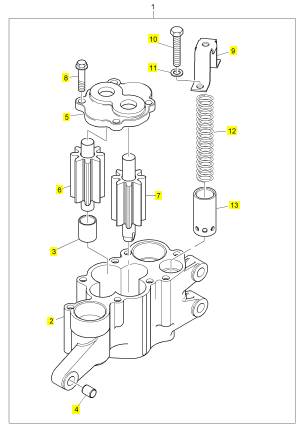

Perkins2506柴油發(fā)動機威爾遜P500E柴油發(fā)電機配件CH10860機油泵

詳細描述

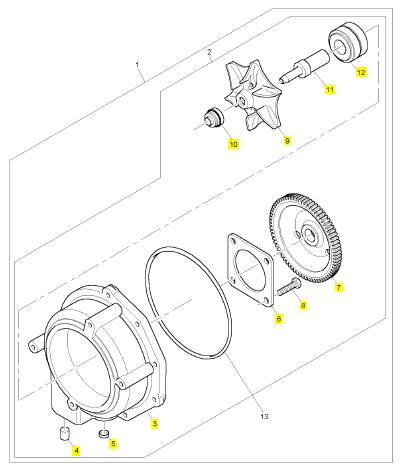

項目 零配件號碼 新件號 描述

1 CH10860 1 CH10860 油泵

(1) CH10860 1 CH10860 油泵

項目 零配件號碼 新件號 描述

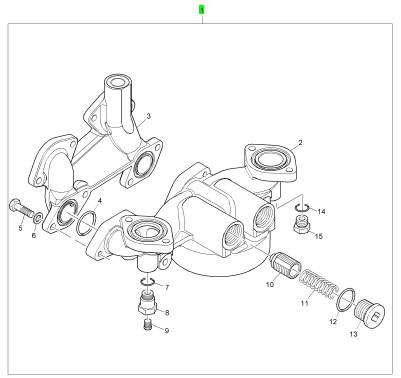

2 1 泵體

3 CH10746 2 CH10746 襯套

4 CH10747 2 CH10747 合釘

5 CH10861 1 CH10861 端蓋

6 CH10862 1 CH10862 軸

7 CH10863 1 CH10863 驅(qū)動軸

8 CH10748 4 CH10748 螺拴

9 CH10736 1 CH10736 承件

10 CH10735 2 CH10735 螺拴

11 CH10541 2 CH10255 墊圈

12 CH10737 1 CH10737 彈簧

13 CH10738 1 CH10738 柱塞

項目 零配件號碼 新件號 描述

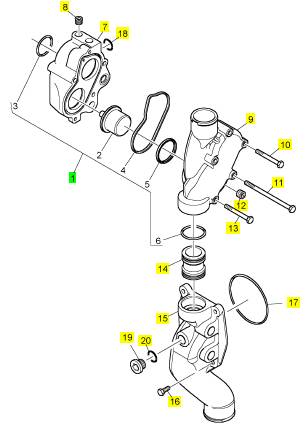

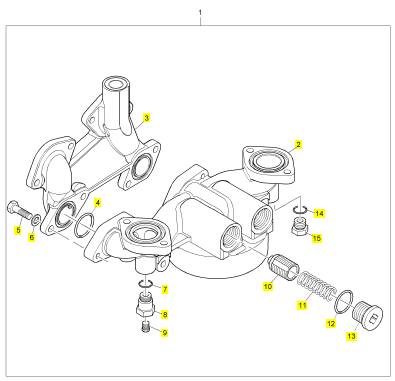

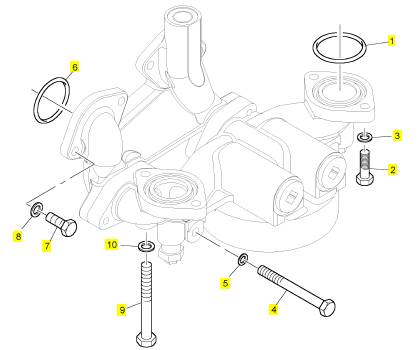

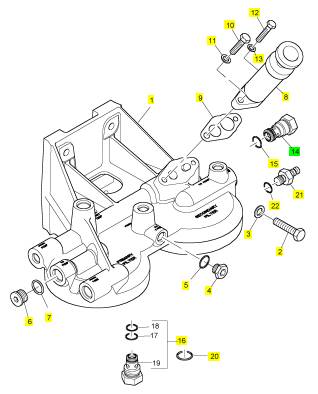

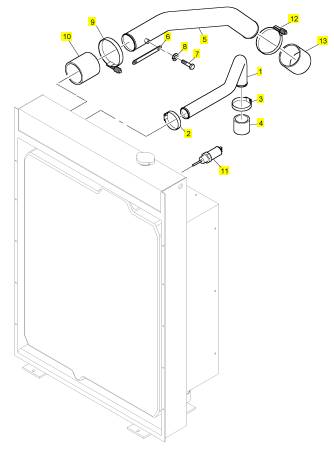

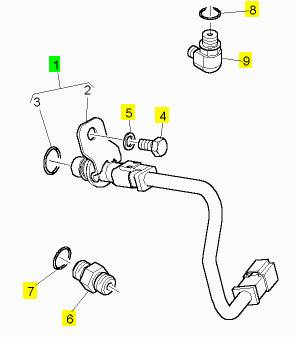

1 KRP1645 1 KRP1645 節(jié)溫器裝備

7 CH11224 1 CH11224 殼

8 CH10260 2 CH10260 栓塞

9 CH10765 1 CH10765 節(jié)溫器殼

10 CH10751 1 CH10751 螺拴

11 CH10753 1 CH10753 螺拴

12 CH10260 1 CH10260 栓塞

13 CH10751 1 CH10751 螺拴

14 CH10752 1 CH10752 管

15 CH11618 1 CH11618 蓋

16 CH10537 5 CH11895 螺拴

17 CH11619 1 CH11619 密封O型圈

18 CH11621 3 CH11621 密封O型圈

19 CH12474 3 CH12474 栓塞

19 CH11622 3 CH11622 栓塞

20 CH11621 1 CH11621 密封O型圈

項目 零配件號碼 新件號 描述

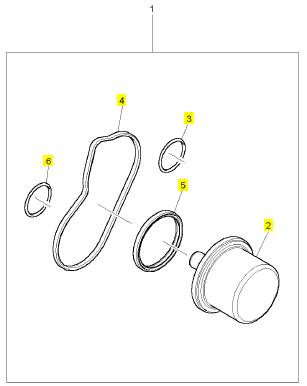

2 CH11620 2 CH11620 節(jié)溫器

3 CH10766 1 CH10766 密封O型圈

4 CH10770 1 CH10770 密封墊 - 節(jié)溫器殼

5 CH10056 2 CH10056 密封墊 - 節(jié)溫器殼

6 CH10755 2 CH10755 密封O型圈

項目 零配件號碼 新件號 描述

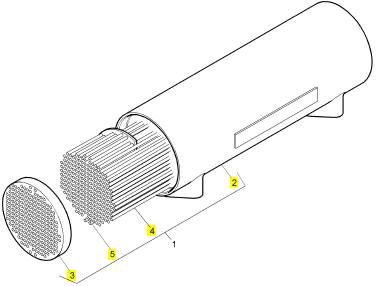

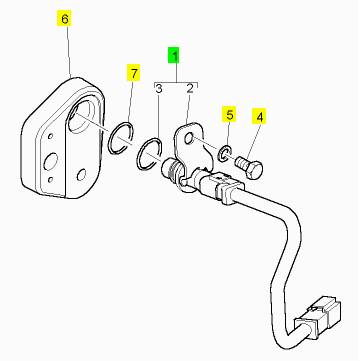

2 1 殼

3 2 端蓋

4 1 TUBESTACK

5 2 栓塞

項目 零配件號碼 新件號 描述

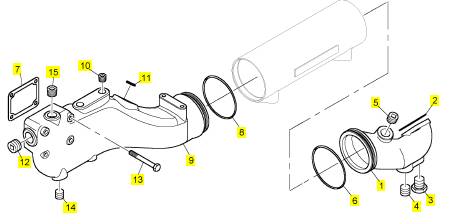

CH10537 2 CH11895 螺拴

CH10541 2 CH10255 墊圈

CH10579 2 CH10579 密封墊

CH10815 4 CH10815 螺拴

CH11059 1 CH11059 架

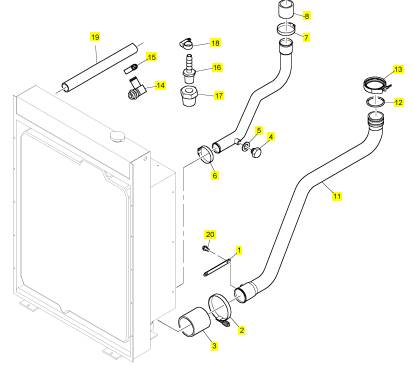

1 CH10769 1 CH10769 水管

2 CH10757 1 CH10757 密封墊

3 CH10263 1 CH10263 栓塞

4 CH10220 1 CH10220 栓塞

5 CH10220 1 CH10220 栓塞

6 CH10544 1 CH10544 密封O型圈

7 CH10579 1 CH10579 密封墊

8 CH10544 1 CH10544 密封O型圈

9 CH10768 1 CH10768 水管

10 CH10260 2 CH10260 栓塞

11 CH10220 1 CH10220 栓塞

12 CH10259 1 CH10259 栓塞

13 CH10751 4 CH10751 螺拴

14 CH10220 1 CH10220 栓塞

15 CH10220 1 CH10220 栓塞

項目 零配件號碼 新件號 描述

CH11139 1 CH12010 密封O型圈

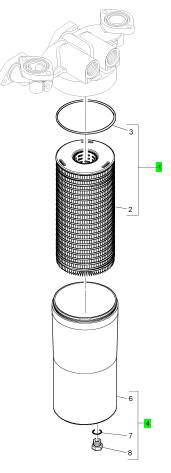

1 CH10929 1 CH10929 濾清器

1 CH10929 1 CH10929 濾清器

4 KRP1719 1 KRP1719 濾清器組合 01/12/2011

4 KRP1570 1 KRP1719 過濾器殼 30/11/2011

項目 零配件號碼 新件號 描述

2 1 濾清器

3 CH12010 1 CH12010 密封墊

項目 零配件號碼 新件號 描述

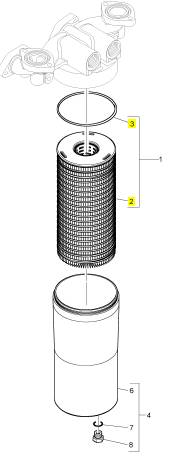

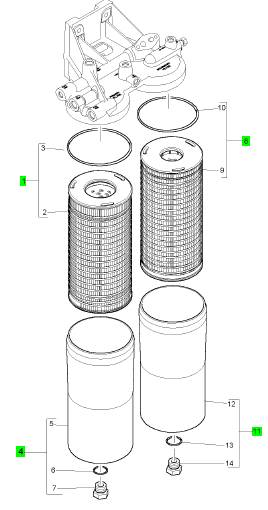

1 CH11250 1 CH11250 燃油濾清器

項目 零配件號碼 新件號 描述

2 1 燃油濾清器

3 CH10818 1 CH10818 燃油濾清器

4 CH10316 2 CH10316 密封O型圈

5 CH10567 4 CH10567 螺拴

6 CH10541 4 CH10255 墊圈

7 CH10133 1 CH10133 密封O型圈

8 CH10888 1 CH10888 承接器

9 CH10262 1 CH10262 栓塞

10 CH10513 2 CH10513 放泄閥

11 CH10819 2 CH10819 彈簧

12 CH10091 2 CH10091 密封O型圈

13 CH10291 2 CH10291 栓塞

14 CH10133 1 CH10133 密封O型圈

15 CH10284 1 CH10284 栓塞

項目 零配件號碼 新件號 描述

1 T400222 2 T400222 密封O型圈

1 CH10816 2 CH10816 密封O型圈

2 CH10567 2 CH10567 螺拴

3 CH10255 2 CH10255 墊圈

3 CH10541 2 CH10255 墊圈

4 CH10814 2 CH10814 螺拴

5 CH10255 2 CH10255 墊圈

5 CH10541 2 CH10255 墊圈

6 CH10224 2 CH10224 密封O型圈

7 CH10815 4 CH10815 螺拴

8 CH10255 4 CH10255 墊圈

8 CH10541 4 CH10255 墊圈

9 CH10751 2 CH10751 螺拴

10 CH10255 2 CH10255 墊圈

10 CH10541 2 CH10255 墊圈

項目 零配件號碼 新件號 描述

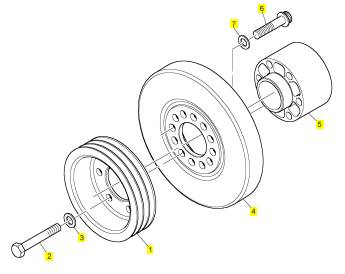

1 CH11648 1 CH11648 曲軸皮帶輪

2 CH10809 6 CH10809 螺拴

2 CH11649 6 CH10809 螺拴

3 CH11651 6 CH11651 墊圈

4 CH11745 1 CH11745 擋板

4 CH11646 1 CH11646 擋板

5 CH11647 1 CH11647 承接器

6 CH11652 12 CH11652 螺拴

7 CH11650 12 CH11650 墊圈

項目 零配件號碼 新件號 描述

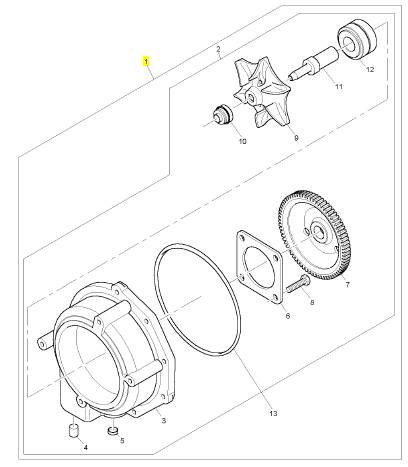

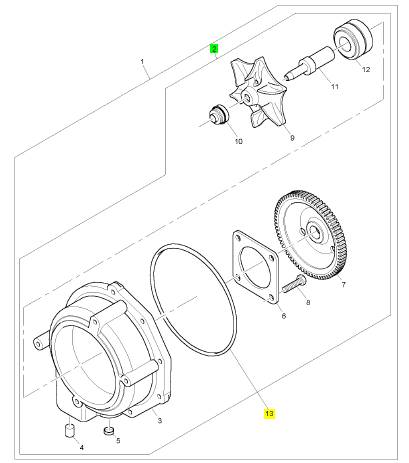

1 KRP1678 1 KRP1715 水泵裝備

1 KRP1644 1 KRP1715 水泵裝備

項目 零配件號碼 新件號 描述

2 1 水泵

13 CH11568 1 CH11568 密封O型圈 裝備

項目 零配件號碼 新件號 描述

3 1 水泵殼

4 CH11634 1 CH11634 過濾器

5 CH11545 1 CH11545 栓塞

6 CH10559 1 CH10559 保有板

7 CH11544 1 CH11544 水泵傳動機構(gòu)

8 CH10557 1 CH10557 螺拴

9 CH11943 1 CH11943 動葉輪

10 CH11941 1 CH12791 密封墊 - 水泵

11 CH11942 1 CH11942 軸

12 CH10558 1 CH10558 輥軸承

項目 零配件號碼 新件號 描述

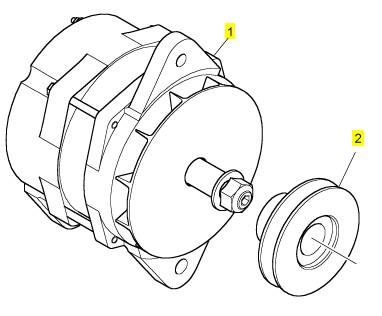

1 CH11087 1 CH11087 交流充電發(fā)電機

(1) CH11087 1 CH11087 交換交流充電發(fā)電機

2 CH11036 1 CH11036 交流充電發(fā)電機皮帶輪

項目 零配件號碼 新件號 描述

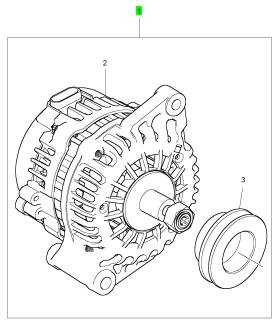

1 CH12876 1 CH12876 交流充電發(fā)電機

項目 零配件號碼 新件號 描述

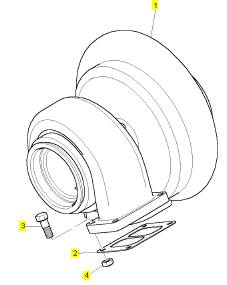

1 CH11947 1 CH11947 渦輪增壓器

2 CH11471 1 CH11471 密封墊 -渦輪增壓器

3 CH10733 4 CH10733 螺拴

4 CH10734 4 CH10734 鎖緊螺母

項目 零配件號碼 新件號 描述

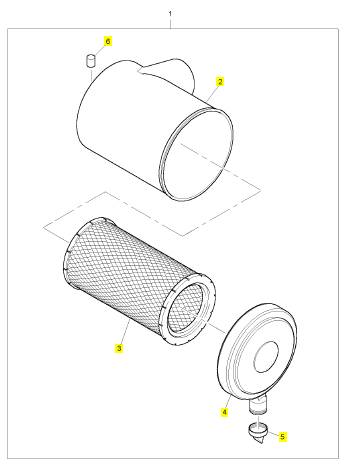

2 1 空氣過濾器體

3 SEV551F/4 1 SEV551F/4 主空氣過濾器

4 CH11287 1 CH11287 蓋

5 CV4178 1 CV4178 閥

6 CV10891 1 CV10891 帽

項目 零配件號碼 新件號 描述

1 CH12434 1 CH12434 燃料過濾器

1 CH11075 1 CH12434 燃料過濾器

2 CH10609 1 CH10609 螺拴

3 CH10255 1 CH10255 墊圈

3 CH10541 1 CH10255 墊圈

4 CH10286 1 CH10286 栓塞

5 CH11880 1 CH11880 密封O型圈

5 CH10046 1 CH10046 密封O型圈

6 CH10287 1 CH10287 栓塞

7 T406205 1 T406205 密封O型圈

7 CH10048 1 CH10048 密封O型圈

8 CH10439 1 CH10439 汽酒共騰泵

9 CH10008 1 CH10008 密封墊

10 CH10557 1 CH10557 螺拴

11 CH10277 1 CH10277 墊圈

11 CH10131 1 CH10131 密封O型圈

12 CH10848 1 CH10848 螺拴

13 CH10086 1 CH10086 墊圈

14 CH10836 1 CH10836 閥

15 T400188 1 T400188 密封O型圈

16 CH12017 1 CH12017 非回路閥

16 CH10457 1 檢查歷史 閥

16 CH12017 1 CH12017 非回路閥

20 CH10131 1 CH10131 密封O型圈

21 CH11410 1 CH11410 栓塞

22 CH11880 1 CH11880 密封O型圈

23 CH11411 1 CH11411 灰塵盾

項目 零配件號碼 新件號 描述

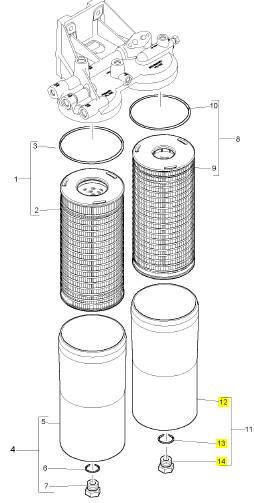

1 CH10930 1 CH10930 前燃料過濾器

4 CH11094 1 檢查歷史 過濾器殼

8 CH10931 1 CH10931 燃料過濾器

11 CH11096 1 檢查歷史 燃料過濾器殼

項目 零配件號碼 新件號 描述

12 1 檢查歷史 過濾器殼

13 CH10046 1 CH10046 密封O型圈

14 CH10284 1 CH10284 栓塞

項目 零配件號碼 新件號 描述

1 CV25001 1 CH12541 開關(guān)

項目 零配件號碼 新件號 描述

CV70392 1 CV70392 墊圈

1 CH11051 1 CH11051 水管

2 ST46410 2 ST46410 夾

2 ST46410 1 ST46410 夾

3 ST46410 3 ST46410 夾

3 ST46410 2 ST46410 夾

4 ST91230 1 ST91230 水管

5 CH11049 1 CH11049 導(dǎo)管

6 CH10979 1 CH10979 托架

7 CV70401 2 CV70401 固定螺釘

8 CV70395 2 CV70395 彈簧塾圈

9 CH11110 2 CH11110 搖臂座

10 CH11128 1 CH11128 水管

11 CH12541 1 CH12541 冷卻器水平開關(guān)

11 CV69938 1 CH12541 開關(guān)

12 CH11110 2 CH11110 搖臂座

13 CH11128 1 CH11128 水管

項目 零配件號碼 新件號 描述

CV70392 1 CV70392 墊圈

CV70395 2 CV70395 彈簧塾圈

CV70401 2 CV70401 固定螺釘

1 CH10979 1 CH10979 托架

2 CH11110 2 CH11110 搖臂座

3 CH11128 1 CH11128 水管

4 CV12198 1 CV12198 排泄栓塞

5 ST49891 1 ST49891 墊圈

6 ST46410 1 ST46410 夾

7 ST46411 2 ST46411 夾

8 ST91237 1 ST91237 水管

11 CH11966 1 CH11966 氣管

12 CH11498 1 CH11498 密封O型圈

13 CH11497 1 CH11497 搖臂座

14 CH12025 1 CH12025 承接器

15 525/46 M 2 525/46 M 水管夾

16 CH12079 1 CH12079 承接器

17 CH12080 1 CH12080 承接器

18 CH12081 1 CH12081 水管夾

19 CH12015 1 CH12015 水管 -冷卻器

20 2314 H002 5 2314 H002 螺旋

20 CH10979 1 CH10979 托架

20 CH11110 2 CH11110 搖臂座

20 CH11128 1 CH11128 水管

20 CV70395 1 CV70395 彈簧塾圈

20 CV70401 1 CV70401 固定螺釘

20 ST46410 1 ST46410 夾

20 ST91230 1 ST91230 水管

項目 零配件號碼 新件號 描述

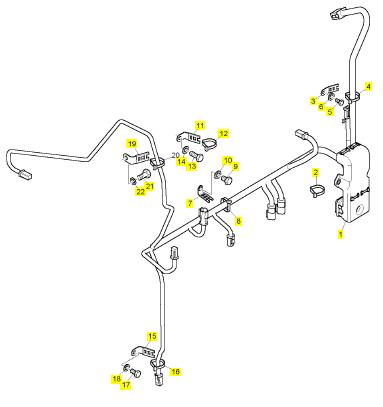

1 CH11985 1 CH11985 線束

2 CH11981 1 CH11981 纜拉桿

3 CH10071 2 T410794 夾

4 CH10054 2 CH10054 纜拉桿

5 CH10794 2 CH11897 螺拴

6 CH10541 2 CH10255 墊圈

7 CH10799 2 CH10799 夾

8 CH10054 2 CH10054 纜拉桿

9 CH10797 2 CH10797 螺拴

10 CH10100 2 CH10100 墊圈

11 CH10072 1 CH10072 夾

12 CH10054 1 CH10054 纜拉桿

13 CH10537 1 CH11895 螺拴

14 CH10541 1 CH10255 墊圈

15 CH10072 2 CH10072 夾

16 CH10054 2 CH10054 纜拉桿

17 CH10794 2 CH11897 螺拴

18 CH10541 2 CH10255 墊圈

19 CH10072 1 CH10072 夾

20 CH10054 1 CH10054 纜拉桿

21 CH10796 1 CH10796 螺拴

22 CH10277 1 CH10277 墊圈

項目 零配件號碼 新件號 描述

CH10867 1 CH10867 間隔器

CH10870 1 CH10870 密封O型圈

1 CH12004 1 KRP1705 速度感應(yīng)傳感器

4 CH10796 1 CH10796 螺拴

5 CH10277 1 CH10277 墊圈

6 CH10873 1 CH10873 連接器

7 CH10132 1 CH10132 密封O型圈

8 CH10133 1 CH10133 密封O型圈

9 CH12001 1 CH12001 肘管

項目 零配件號碼 新件號 描述

1 CH12003 1 KRP1700 速度感應(yīng)傳感器

4 CH10796 1 CH10796 螺拴

5 CH10277 1 CH10277 墊圈

6 CH10867 1 CH10867 間隔器

7 CH10870 1 CH10870 密封O型圈

項目 零配件號碼 新件號 描述

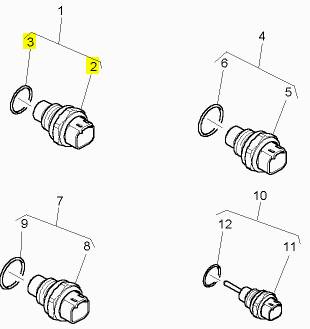

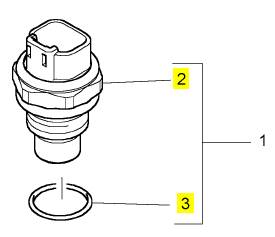

2 1 油壓感應(yīng)傳感器裝備

3 CH10132 1 CH10132 密封O型圈

項目 零配件號碼 新件號 描述

2 1 氣壓感應(yīng)傳感器

3 T409314 1 T409314 密封O型圈

3 CH10132 1 CH10132 密封O型圈

項目 零配件號碼 新件號 描述

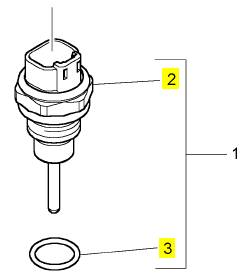

2 CH12, , 652 1 CH12652 氣壓感應(yīng)傳感器

3 CH11880 1 CH11880 密封O型圈

3 CH10133 1 CH10133 密封O型圈

項目 零配件號碼 新件號 描述

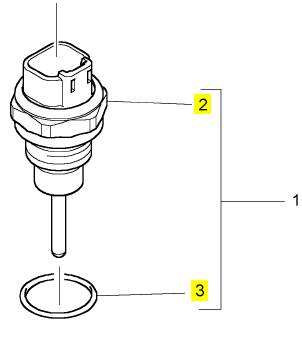

2 1 溫度感應(yīng)傳感器

3 CH10146 1 CH10146 密封O型圈

項目 零配件號碼 新件號 描述

2 1 溫度感應(yīng)傳感器

3 T406205 1 T406205 密封O型圈

3 CH10230 1 CH10230 密封O型圈

項目 零配件號碼 新件號 描述

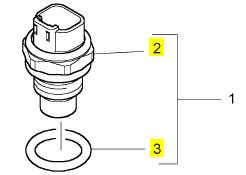

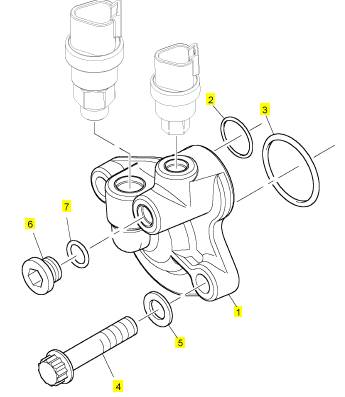

1 CH10907 1 CH10907 承接器

2 CH10875 1 CH10875 密封O型圈

3 CH10228 1 CH10228 密封O型圈

4 T400184 2 T400184 螺拴

4 CH10567 2 CH10567 螺拴

5 CH10541 2 CH10255 墊圈

6 CH10285 1 CH10285 栓塞

6 CH10282 1 CH10282 栓塞

7 T409314 1 T409314 密封O型圈

7 CH10132 1 CH10132 密封O型圈

Operat ion

and

Maint enance

Manual

2506-15

Industrial

Engine

MGA (Engine)

MGB (Engine)

MGD (Engine)

This document has been printed from SPI². Not for Resale

![]()

![]() Important

Important

Safety Information

Most accidents that involve product operation, maintenance and repair are caused by failure to

observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially

hazardous situations before an accident occurs. A person must be alert to potential hazards. This

person should also have the necessary training, skills and tools to perform these functions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard

warnings are not heeded, bodily injury or death could occur to you or to other persons.

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as

“DANGER”, “WARNING” or “CAUTION”. The Safety Alert “WARNING” label is shown below.

|

Attention! Become Alert! Your Safety is Involved.

The message that appears under the warning explains the hazard and can be either written or

pictorially presented.

Operations that may cause product damage are identified by “NOTICE” labels on the product and in

this publication.

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The information, specifications, and illustrations in this publication are on the basis of information that

was available at the time that the publication was written. The specifications, torques, pressures,

measurements, adjustments, illustrations, and other items can change at any time. These changes can

affect the service that is given to the product. Obtain the complete and most current information before

you start any job. Perkins dealers or Perkins distributors have the most current information available.

When

replacement parts are

required for

this

|

replacement parts.

Failure to heed this warning can lead to prema-

death.

This document has been printed from SPI². Not for Resale

![]()

![]() SEBU8313

SEBU8313

3

Table of Contents

Table

of

Contents

Warranty Section

Warranty Information ............................................ 75

Foreword ................................................................. 4

Safety Section

Safety Messages .................................................... 5

General Hazard Information ................................... 6

Burn Prevention ...................................................... 7

Fire Prevention and Explos ion Prevention .............. 8

Crushing Prevention and Cutting Prevention ........ 10

Mounting and Dismounting ................................... 10

Before Starting Engine ........................................... 11

Engine Starting ...................................................... 11

Engine Stopping .................................................... 11

Electrical System .................................................. 12

Engine Electronics ................................................ 13

Product Information Section

General Information .............................................. 14

Model Views ......................................................... 15

Product Identification Information ........................ 18

Operation Section

Lifting and Storage ................................................ 23

Gauges and Indicators .......................................... 24

Features and Controls .......................................... 25

Engine Diagnostics ............................................... 30

Engine Starting ..................................................... 32

Engine Operation .................................................. 34

Engine Stopping ................................................... 35

Cold Weather Operation ....................................... 36

Maintenance Section

Refill Capacities .................................................... 39

Maintenance Interval Schedule ............................ 51

Index Section

Index ..................................................................... 76

This document has been printed from SPI². Not for Resale

![]() 4

4

Foreword

SEBU8313

Foreword

Recommended se

rvice should be performed at the

Literature Information

This manual contains safety, operation instructions,

lubrication and maintenance information. This

manual should be stored in or near the engine area

in a literature holder or literature storage area. Read,

study and keep it with the literature and engine

information.

English is the primary language for all Perkins

publications. The English used facilitates translation

and c onsistency.

Some photographs or illustrations in this manual

show details or attachments that may be different

from your engine. Guards and covers may have

been removed for illustrative purposes. Continuing

improvement and advancement of product design

may have caused changes to your engine which are

not included in this manual. Whenever a question

arises regarding your engine, or this manual, please

consult with your Perkins dealer or your Perkins

distributor for the latest available information.

Safety

This safety section lists basic safety prec autions.

In addition, this section identifies hazardous,

warning situations. Read and understand the basic

precautions listed in the safety section before

operating or performing lubrication, maintenance and

repair on this product.

Operation

Operating techniques outlined in this manual are

basic. They assist with developing the skills and

techniques required to operate the engine more

efficiently and economically. Skill and techniques

develop as the operator gains k nowledge of the

engine and its c apabilities.

The operation section is a reference for operators.

Photographs and illustrations guide the operator

through procedures of inspecting, starting, operating

and stopping the engine. This section also includes a

discussion of electronic diagnostic information.

Maintenance

The maintenance sec tion is a guide to engine care.

The illustrated, step-by-step instructions are grouped

by service hours and/or calendar time maintenance

intervals. Items in the maintenance schedule are

referenced to detailed instructions that follow.

appropriate intervals as indicated in the Maintenance

Interval Schedule. The actual operating environment

of the engine also governs the Maintenance Interval

Schedule. Therefore, under extremely s evere,

dusty, wet or freezing cold operating conditions,

more frequent lubrication and maintenance than is

specified in the Maintenance Interval Schedule may

be necessary.

The maintenance schedule items are organized for

a preventive maintenance management program. If

the preventive maintenance program is followed, a

periodic tune-up is not required. The implementation

of a preventive maintenance management program

should minimize operating costs through cost

avoidances resulting from reductions in unscheduled

downtime and failures.

Maintenance Intervals

Perform maintenance on items at multiples of

the original requirement. We recommend that the

maintenance schedules be reproduced and displayed

near the engine as a convenient reminder. We also

recommend that a maintenance record be maintained

as part of the engine’s permanent record.

Your authoriz ed Perk ins dealer or your Perkins

distributor can ass ist you in adjusting your

maintenance schedule to meet the needs of your

operating environment.

Overhaul

Major engine overhaul details are not covered in

the Operation and Maintenance Manual except

for the interval and the maintenance items in that

interval. Major repairs should only be carried out by

Perkins authorized personnel. Your Perkins dealer

or your Perkins distributor offers a variety of options

regarding overhaul programs. If you experience

a major engine failure, there are also numerous

after failure overhaul options available. Consult with

your Perkins dealer or your Perk ins distributor for

information regarding these options .

California Proposition 65 Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer,

birth defects, and other reproductive harm. Battery

posts, terminals and related accessories contain lead

and lead compounds. Wash hands after handling.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]() SEBU8313

SEBU8313

5

Safety Section

Safety Messages

Safety

Section

Safety Messages

i02581679

There may be several specific warning signs on your

engine. The exact location and a description of the

warning signs are reviewed in this section. Please

become familiar with all warning signs.

Ensure that all of the warning signs are legible. Clean

the warning signs or replace the warning signs if

the words cannot be read or if the illustrations are

not visible. Use a cloth, water, and soap to clean

the warning signs. Do not use solvents, gasoline, or

other harsh chemicals. Solvents, gasoline, or harsh

chemicals could loosen the adhesive that secures the

warning signs. The warning signs that are loosened

could drop off of the engine.

Replace any warning sign that is damaged or

missing. If a warning sign is attached to a part of the

engine that is replaced, install a new warning sign on

the replacement part. Your Perkins dealer or your

distributor can provide new warning signs.

(1) Universal Warning

Do not operate or work on this equipment unless

you have read and understand the instructions

and warnings in the Operation and Maintenance

Manuals. Failure to follow the instructions or

heed the warnings could result in serious injury

or death.

Illustration 1

Typical example

g01154807

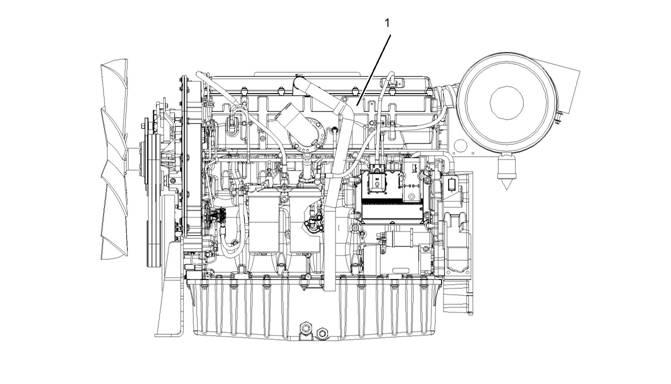

The Universal Warning label (1) is located on both

sides of the engine. Refer to illustration 2.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]() 6

6

Safety Section

General Hazard Information

SEBU8313

Illustration 2

Typical example

g01294688

i02328435

General Hazard Information

Illustration 4

g00702020

Illustr

ation 3

g00104545

Wear a hard hat, protective glasses, and other

protective equipment, as required.

Do not wear loose clothing or jewelry that can snag

on controls or on other parts of the engine.

Attach a “Do Not Operate” warning tag or a similar

warning tag to the start switch or to the controls

before you service the equipment or before you

repair the equipment.

Make sure that all protective guards and all covers

are secured in place on the engine.

Keep the engine free from foreign material. Remove

debris, oil, tools, and other items from the deck, from

walkways, and from steps.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]() SEBU8313

SEBU8313

7

Safety Section

Burn Prevention

Never put maint

enance fluids into glass containers.

Drain all liquids into a suitable container.

Obey all local regulations for the disposal of liquids.

Use all cleaning solutions with care.

Report all necessary repairs.

Do not allow unauthorized personnel on the

equipment.

Ensure that the power supply is disconnected before

you work on the bus bar or the glow plugs.

Perform maintenance on the engine with the

equipment in the servicing position. Refer to the

Illustration 5

g00687600

OEM information for the procedure for placing the

equipment in the servicing position.

Pressure Air and Water

Pressurized air and/or water can cause debris

and/or hot water to be blown out. This could result in

personal injury.

The direct application of pressurized air or

pressurized water to the body could result in personal

injury.

When pressurized air and/or water is used for

cleaning, wear protective clothing, protective shoes,

and eye protection. Eye protection includes goggles

or a protective face shield.

The maximum air pressure for cleaning purposes

mus t be below 205 kPa (30 psi). The maximum

water pressure for cleaning purposes must be below

275 k Pa (40 psi).

Fluid Penetration

Pressure can be trapped in the hydraulic circuit long

after the engine has been stopped. The pressure can

cause hydraulic fluid or items such as pipe plugs to

escape rapidly if the pressure is not relieved correctly.

Do not remove any hydraulic components or parts

until pressure has been relieved or personal injury

may oc cur. Do not disassemble any hydraulic

components or parts until pressure has been relieved

or personal injury may occur. Refer to the OEM

information for any procedures that are required to

relieve the hydraulic press ure.

Always use a board or cardboard when you check

for a leak. Leaking fluid that is under pressure can

penetrate body tissue. Fluid penetration can cause

serious injury and possible death. A pin hole leak can

cause severe injury. If fluid is injected into your skin,

you must get treatment immediately. Seek treatment

from a doctor that is familiar with this type of injury.

Containing Fluid Spillage

Care must be taken in order to ensure that fluids

are contained during performance of inspection,

maintenance, testing, adjusting and repair of the

engine. Make prov ision to collect the fluid with a

suitable container before any compartment is opened

or before any component is disassembled.

• Only use the tools that are suitable for collecting

fluids and equipment that is suitable for collecting

fluids.

• Only use the tools that are suitable for containing

fluids and equipment that is suitable for containing

fluids.

Obey all local regulations for the disposal of liquids.

i02334785

Burn Prevention

Do not touch any part of an operating engine.

Allow the engine to cool before any maintenance is

performed on the engine.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]() 8

8

Safety Section

Fire Prevention and Ex plosion Prevention

SEBU8313

Contact with high pressure fuel may cause fluid

penetration and burn hazards. High pressure fu-

el spray may cause a fire hazard. Failure to fol-

low these inspection, maintenance and service in-

structions may cause personal injury or death.

After the engine has stopped, you must wait for 60

seconds in order to allow the fuel pressure to be

purged from the high pressure fuel lines before any

service or repair is performed on the engine fuel lines.

Allow the pressure to be purged in the air system, in

the hydraulic system, in the lubrication system, or in

the cooling sys tem before any lines, fittings or related

items are disconnected.

Coolant

When the engine is at operating temperature, the

engine coolant is hot. The coolant is also under

Fire Prevention and

Prevention

Illustration 6

i02320721

Explosion

g00704000

pressure. The radiator and all lines to the heaters or

to the engine contain hot coolant.

Any contact with hot coolant or with steam can cause

severe burns. Allow cooling system components to

cool before the cooling system is drained.

Check the coolant level after the engine has stopped

and the engine has been allowed to cool.

Ensure that the filler cap is cool before removing the

filler cap. The filler c ap must be cool enough to touch

with a bare hand. Remove the filler cap slowly in

order to relieve pressure.

Cooling system conditioner contains alkali. Alkali can

cause personal injury. Do not allow alkali to contact

the s kin, the eyes, or the mouth.

Oils

Hot oil and hot lubricating components can cause

personal injury. Do not allow hot oil to contact the

skin. Also, do not allow hot components to contact

the skin.

Batteries

Electrolyte is an acid. Electrolyte can cause personal

injury. Do not allow electrolyte to contact the skin or

the eyes. Always wear protective glasses for servicing

batteries. Wash hands after touching the batteries

and connectors. Use of gloves is recommended.

All fuels, most lubricants, and some coolant mixtures

are flammable.

Flammable fluids that are leaking or spilled onto hot

surfaces or onto electrical components can cause

a fire. Fire may cause personal injury and property

damage.

After the emergency stop button is operated ensure

that you allow 15 minutes, before the engine covers

are removed.

Determine whether the engine will be operated in an

env ironment that allows combustible gases to be

drawn into the air inlet system. These gases could

cause the engine to overspeed. Personal injury,

property damage, or engine damage could result.

If the application involves the presence of combustible

gas es, consult your Perkins dealer and/or your

Perkins distributor for additional information about

suitable protection devices.

Remove all flammable combustible materials or

conductive materials s uch as fuel, oil, and debris from

the engine. Do not allow any flammable combustible

materials or conductive materials to accumulate on

the engine.

Store fuels and lubricants in correctly marked

containers away from unauthoriz ed persons. Store

oily rags and any flammable materials in protective

containers. Do not smoke in areas that are used for

storing flammable materials.

Do not expose the engine to any flame.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]() SEBU8313

SEBU8313

9

Safety Section

Fire Prevention and Explosion Prevention

Exhaust shield

s (if equipped) protect hot exhaust

components from oil or fuel spray in case of a line,

a tube, or a seal failure. Exhaust shields must be

installed correctly.

Do not weld on lines or tanks that contain flammable

fluids. Do not flame cut lines or tanks that contain

flammable fluid. Clean any such lines or tanks

thoroughly with a nonflammable solvent prior to

welding or flame cutting.

Wiring must be kept in good condition. All electrical

wires must be correctly routed and securely attached.

Check all electrical wires daily. Repair any wires

that are loose or frayed before you operate the

engine. Clean all electrical connections and tighten

all electrical connections.

Eliminate all wiring that is unattached or unnecessary.

Do not use any wires or cables that are smaller than

the recommended gauge. Do not bypass any fuses

and/or circuit breakers.

Arcing or sparking could cause a fire. Secure

Illustration 7

g00704059

connections, recommended wiring, and correctly

maintained battery cables will help to prevent arcing

or sparking.

Use caution when you are refueling an engine. Do

not smoke while you are refueling an engine. Do not

refuel an engine near open flames or sparks. Always

stop the engine before refueling.

Contact with high pressure fuel may cause fluid

penetration and burn hazards. High pressure fu-

el spray may cause a fire hazard. Failure to fol-

low these inspection, maintenance and service in-

structions may cause personal injury or death.

After the engine has stopped, you must wait for 60

seconds in order to allow the fuel pressure to be

purged from the high pressure fuel lines before any

serv ice or repair is performed on the engine fuel lines.

Ensure that the engine is stopped. Inspect all lines

and hoses for wear or for deterioration. The hoses

mus t be correctly routed. The lines and hoses must

have adequate support and s ecure clamps.

Oil filters and fuel filters must be correctly installed.

The filter housings mus t be tightened to the correct

torque. Refer to the Disassembly and Assembly

manual for more information.

Illustration 8

g00704135

Gases from a battery can explode. Keep any open

flames or sparks away from the top of a battery. Do

not smoke in battery charging areas.

Never check the battery charge by placing a metal

object across the terminal posts. Use a voltmeter or

a hydrometer.

This document has been printed from SPI². Not for Resale

![]() 10

10

Safety Section

Crushing Prevention and Cutting Prevention

SEBU8313

Incorrect jump

er cable connections can cause

i01359666

an explosion that can result in injury. Refer to

the Operation Section of this manual for specific

instructions.

Crushing

Prevention

and

Do not charge a frozen battery. This may caus e an

explosion.

The batteries must be kept clean. The covers

(if equipped) must be kept on the cells. Use the

recommended cables, connections, and battery box

covers when the engine is operated.

Fire Extinguisher

Mak e sure that a fire extinguisher is available. Be

familiar with the operation of the fire extinguisher.

Inspect the fire extinguisher and service the fire

extinguisher regularly. Obey the recommendations

on the instruction plate.

Lines, Tubes and Hoses

Do not bend high pressure lines. Do not strike high

pressure lines. Do not install any lines that are

damaged.

Leaks can cause fires. Consult your Perkins dealer

or your Perkins distributor for replacement parts.

Replace the parts if any of the following conditions

are present:

• High press ure fuel line or lines are removed.

• End fittings are damaged or leaking.

• Outer coverings are chafed or cut.

• Wires are exposed.

• Outer coverings are ballooning.

• Flexible part of the hoses are kinked.

• Outer covers have embedded armoring.

• End fittings are displaced.

Make sure that all clamps , guards, and heat shields

are installed correctly. During engine operation, this

will help to prevent vibration, rubbing against other

parts, and excessive heat.

Cutting Prevention

Support the component properly when work beneath

the component is performed.

Unless other maintenance instructions are provided,

nev er attempt adjus tments while the engine is

running.

Stay clear of all rotating parts and of all moving

parts. Leave the guards in place until maintenance

is performed. After the maintenance is performed,

reinstall the guards.

Keep objects away from moving fan blades. The fan

blades will throw objects or cut objects.

When objects are struck, wear protective glasses in

order to avoid injury to the eyes.

Chips or other debris may fly off objects when objects

are struck. Before objects are struck, ensure that no

one will be injured by flying debris.

i01372247

Mounting and Dismounting

Inspect the steps, the handholds, and the work area

before mounting the engine. Keep these items clean

and keep these items in good repair.

Mount the engine and dismount the engine only at

locations that have steps and/or handholds. Do not

climb on the engine, and do not jump off the engine.

Face the engine in order to mount the engine or

dismount the engine. Maintain a three-point contact

with the steps and handholds. Use two feet and one

hand or use one foot and two hands. Do not use any

controls as handholds.

Do not stand on c omponents which cannot support

your weight. Use an adequate ladder or use a work

platform. Secure the climbing equipment so that the

equipment will not move.

Do not carry tools or supplies when you mount the

engine or when you dismount the engine. Use a hand

line to raise and lower tools or supplies.

This document has been printed from SPI². Not for Resale