產(chǎn)品中心

Perkins3012柴油發(fā)動機威爾遜P850E柴油發(fā)電機配件連桿

詳細描述

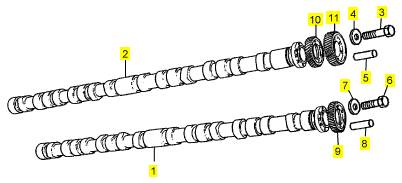

項目 零配件號碼 最近的部分號碼 描述

1 CV14543 1 CV14543 凸輪軸

2 CV14544 1 CV14544 凸輪軸

3 CV13282 6 CV13282 螺拴

4 2131 A010 6 2131 A010 墊圈

5 ST45780 1 ST45780 合釘

6 CV17071 6 CV17071 固定螺釘

7 2131 A008 6 2131 A008 墊圈

8 ST45778 1 ST45778 彈簧銷

9 CV1214 1 CV1214 凸輪軸傳動機構(gòu)

10 CV1215 1 CV1215 凸輪軸傳動機構(gòu)

11 CV8563 1 CV8563 凸輪軸傳動機構(gòu)

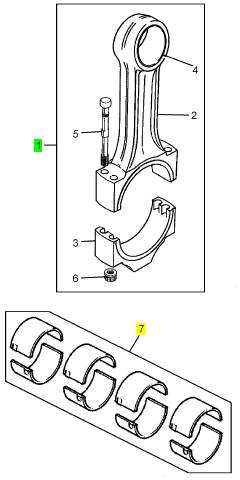

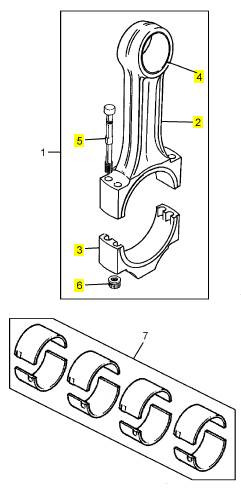

項目 零配件號碼 最近的部分號碼 描述

1 CV19260 12 連桿組合

7 KRP3010/010 1 KRP3010/010 連桿 BRG 裝備 -U/S

7 KRP3010/020 1 KRP3010/020 連桿 BRG 裝備 -U/S

7 KRP3010/030 1 KRP3010/030 連桿 BRG 裝備 -U/S

7 KRP3010/040 1 KRP3010/040 連桿 BRG 裝備 -U/S

7 KRP3010 3 KRP3010 連桿瓦裝備

項目 零配件號碼 最近的部分號碼 描述

2 1 桿

3 1 帽

4 CV19259 1 CV19259 連桿小的一端襯套

5 CV999 4 CV999 連桿螺拴

6 CV206 4 CV206 連桿螺帽

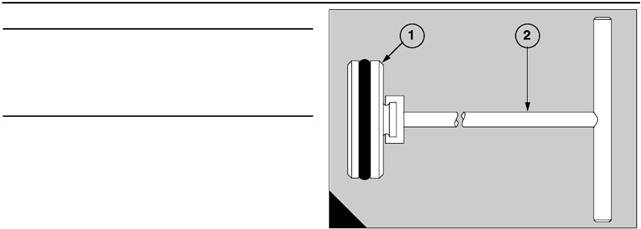

2 Fit the dowel, which provides the location for the

flywheel, into its hole in the end face of the crankshaft

and align the guide (A5) for the seal, to ensure that

the dowel enters a hole in the guide. The hole is a

clearance fit on the dowel. Make a temporary mark

on the flange of the crankshaft to show the alignment

of the three bolt holes in the guide.

3 Lift away the guide and fit the three special studs

(A2) of the kit into the three relevant bolt holes in the

end face of the crankshaft (A1). Tighten lightly each

special stud, engage correctly the dowel in the hole

and hold the guide against the end face of the

crankshaft.

4 Insert the three cap screws (A3) of the kit through

the guide into the special studs and tighten lightly the

cap screws.

5 Before the oil seal (A7) is fitted, c heck again the

guide and the crank shaft for dirt or for a rough surface

finish which could damage the lip of the oil seal.

6 Apply a small amount of clean engine lubricating oil

to the guide and the flange of the crankshaft, remove

and discard the yellow inner sleeve, and fit the seal

onto the guide. The lip of the seal is toward the

crankcase.

7 Slide the collar (A6) onto the guide until the face of

the collar presses against the outer face of the oil

seal.

A

129

Caution:

This tool is used for both CV8/3008 and

CV12/3012 engines and the collar is marked to show

the correct assembly for each engine. It is important

that the collar is fitted correctly. For CV12/3012

engines, the edge of the shorter of the two shoulders

which are machined on the collar must be against the

oil seal.

8 Fit the top plate (A4) onto the central stud and

engage its shoulder in the collar. Lightly lubricate the

thread of the stud and also the thrust washer. Fit the

nut and the thrust washer to retain the top plate. Use

the correct spanner to tighten the nut until the larger

diameter of the collar is in contact with the face of the

housing. Remove the complete tool.

9 Fit the flywheel, operation 22-1.

82

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

![]() Crankshaft

Crankshaft

14

To remove and to fit

Special tools:

Lift adaptor, crankshaft VP 666

Slide hammer, 21825 849

Remover tool, 21825 858

Guide pin, 21825 843

14-4

To remove

1 Fit the engine in the build stand, operation 16-1.

2 Remove the fan adaptor and the front mountings,

operation 21-10.

3 Remove the flywheel and the flywheel housing,

operation 22-4.

4 Remove the timing case and the timing gears,

operation 15-5.

5 Remove the lubricating oil sump, operation 19-1 or,

for new engines, operation 19-5.

6 For early engines, remove the sump adaptor,

operation 19-3.

7 Remove the lubricating oil pump, operation 19-7.

8 Turn the crankshaft until one of the pistons of ’A’

bank is at the bottom of its stroke and remove the four

nuts of the big end bearing. Withdraw the bearing cap

with the bearing. Fit the guide pin, 21825 843, on to

one of the bolts of the big end.

9 Push the assembly of the piston and the connecting

rod into its bore to the end of its stroke. Push carefully

to prevent damage to the top of the piston and the

valves.

10 Similarly, repeat the operation for the remainder of

the assemblies. Move the guide pin as necessary.

11 Turn the crankcase for acc ess to the big end

bearings of ’B’ bank. Repeat the operation for the

assemblies of pistons and connecting rods, as for ’A’

bank.Loosen all the bolts that retain the main bearing

caps. Release and remove the side bolts.

Perkins Engines Company Limited

83

This document has been printed from SPI². Not for Resale

14

14

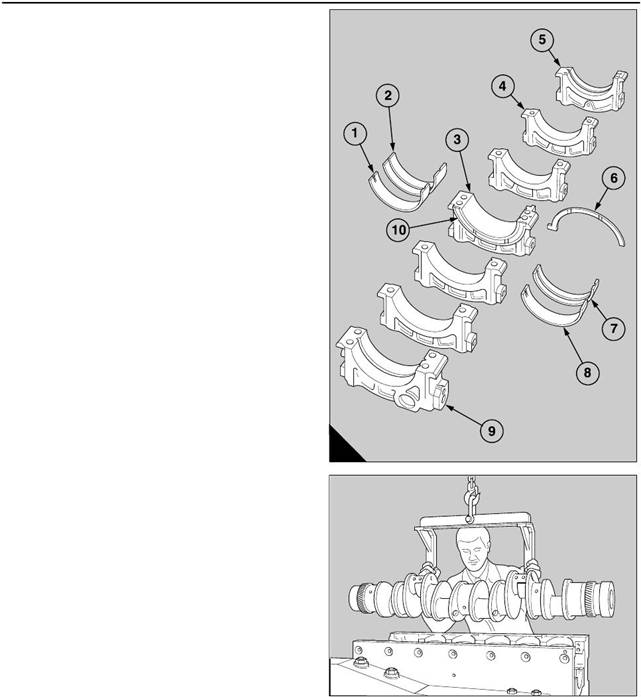

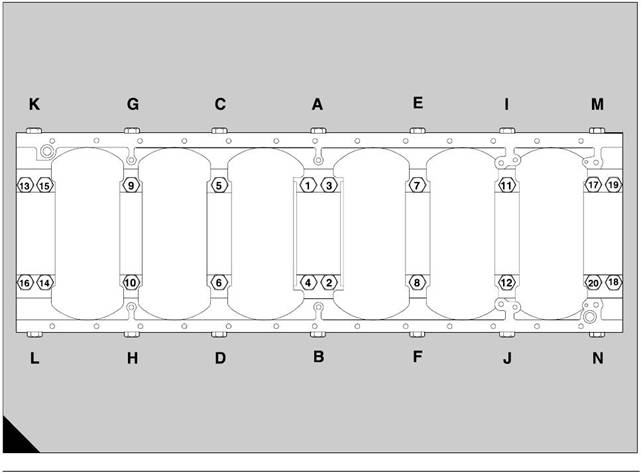

12 Remove the bolts from each main bearing cap and

remov e the caps. If necessary use the slide hammer,

21825 849, with the remover tool, 21825 858, to

withdraw each main bearing cap (A3,4,5,9) and its

lower half bearing (A1,8). When the central main

bearing cap (A3) is removed, remove also the lower

halves of the thrust washers (A10).

13 Slide the upper halves of the thrust washers (A6)

from their recesses around the central main journal.

Use the lift adaptor VP 666 to lift the crankshaft from

the crankcase and put it on wooden vee blocks.

Remove the upper halves of the main bearings (A2,7)

from the crankcase and also the upper halv es of the

thrust washers.

To fit

1 Check for dirt and debris in the passages for the

engine lubricating oil of the crankcase, and also of the

front and the rear main bearing caps (A5,9). Clean

thoroughly the bearing housings and the bearing

caps, and also the main journals and the crank pins of

the crankshaft.

2 Check also for dirt and debris in the passages of the

connecting rods and clean thoroughly the bearing

surfaces of the big ends.

3 Ensure that the half bearings and the thrust

washers for the main journals of the crankshaft are

absolutely clean, and fit the upper half bearings into

their housings in the crankcase. Give a full

application of clean engine lubricating oil to all of the

bearing surfaces.

4 Also, apply clean engine lubricating oil to lubricate

fully the main journals of the crankshaft. Use the lifting

beam VP 666 to lower the crankshaft into the

crankcase (B). Ensure that the 16 tapped holes in the

end face of the c rankshaft are furthest from the build

stand, and are at the end of the crankcase to which

the timing case is fitted.

5 Apply engine lubricating oil to the upper halves of

the thrust washers and insert them into their recesses

on each side of the central main bearing. Ensure that

the face of lead bronze on each washer is toward the

A

B

206

201

crankshaft web.

84

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

14

14

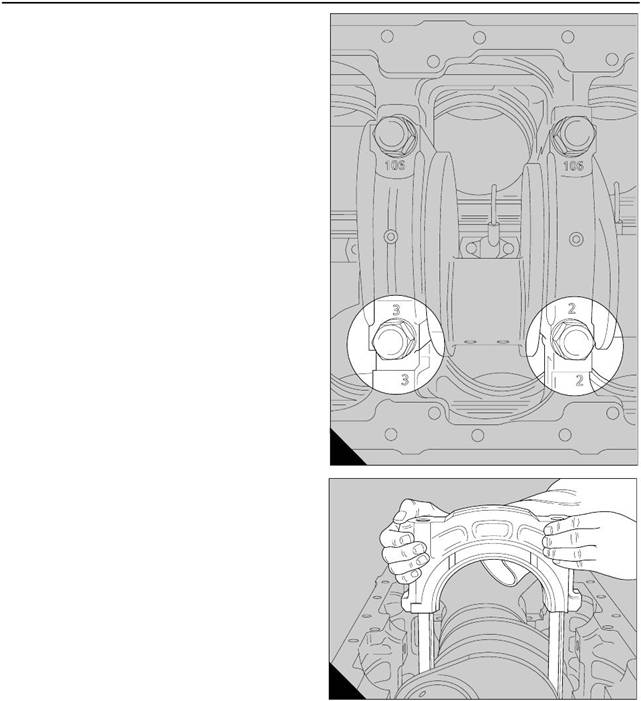

6 Fit the lower halves of the main bearings into the

bearing caps and give a full application of clean

engine lubricating oil to all of the bearing surfaces. Fit

all the ass emblies of the bearing caps except the

bearing cap for the central main bearing. Ensure that

the numbers which are stamped on each bearing cap,

to give its relationship, match the numbers which are

stamped on the crankcase, as shown (A).

7 Apply a minimum amount of grease to the recesses

at the sides of the bearing cap for the central main

bearing and insert the lower halves of the thrust

washers into the recesses. Ensure that the face of

lead bronze on each washer is away from the bearing

cap.

8 Fit carefully the assembly of the bearing cap for the

central main bearing. Ensure that the halves of the

thrust washers remain in their positions during the

operation.

9 Apply engine lubricating oil to the threads, and

under the heads, of the main bolts which retain the

main bearing caps. Fit carefully each bolt into its

location. Do NOT allow the bolts to fall into the holes

because the threads could be damaged. Insert fully

each main bolt by hand only.

Caution: On new engines, the bolts fitted to the front,

centre and rear bearing caps, are different and are

fitted with hardened washers. Ensure that the special

washers are fitted to the bolts before the bolts are

fitted to the engine. Do NOT fit any other type of

washer.

Caution: If a new front, centre or rear bearing cap is

fitted, do NOT fit the old type of bolts. The new bolts

and special washers MUST be used.

10 Apply engine lubricating oil to the threads, and

under the heads, of the side bolts which hold rigidly

the main bearing caps. Fit the plain washers on the

M16 bolts and the ’Dowty’ sealing washers on the

M14 bolts. Insert fully each bolt, by hand, through the

side walls of the crankcase.

11 Check that the faces which are machined on the

front and the rear of each main bearing cap are

A

B

203

202

aligned with the faces in the crankcase. Tighten

lightly all of the main bolts and then all of the side

bolts.

12 Tighten, in the sequence shown in page 86/B, all

the main bolts of the bearing caps by increments of 50

Nm (37 lbf ft) until the maximum torque of 177 Nm

(130 lbf ft) is applied. At the end of this phase of the

operation, the main bolts of the main bearing caps at

the front, at the c entre and at the rear are tightened

fully.

Caution: Check frequently that the crankshaft can

rotate freely while the bolts are tightened.

Perkins Engines Company Limited

85

This document has been printed from SPI². Not for Resale

14

14

13 Continue to tighten the bolts - numbers 5 to 12 (B)

- for the remainder of the main bearing caps, until the

maximum torque of 488 Nm (360 lbf ft) is applied.

14 Tighten all the side bolts, in alphabetical

sequence, until a maximum torque of 114 Nm (85 lbf

ft) is applied. At the end of this phase of the operation,

the side bolts of the front, central and rear main

bearings are tightened fully.

15 Continue to tighten the remainder of the side bolts

- letters C to J (B) - in alphabetical sequence, until a

maximum torque of 177 Nm (130 lbf ft) is applied.

16 Put a dial test indicator with a magnetic base on

the end face of the crankcase. Set the button of the

dial test indicator on the end of the crankshaft (A).

Use a lever to move the crankshaft backward and

forward against the thrust washers and check the

readings on the dial test indicator. Permissible end-

float is 0,10 to 0,30 mm (0.004 to 0.012 in).

Turn the crankcase in the build stand so that the ’A’

bank cylinders are horizontal. Fit each of the

connecting rods, of the ’A’ bank cylinders, to their

respective crank pins, operation 13-3.

A

205

A

192

86

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

17 When all of the ’A’ bank connecting rods have

been fitted, turn the build stand until the ’B’ bank

cy linders are horizontal and use the same procedure

to fit the connecting rods of the ’B’ bank.

18 Set a dial test indicator as shown (page 67/B) and

check the end float of each big end. The permissible

end float is 0,2 to 0,4 mm (0.008 to 0.016 in).

19 Ensure that the crankshaft turns freely.

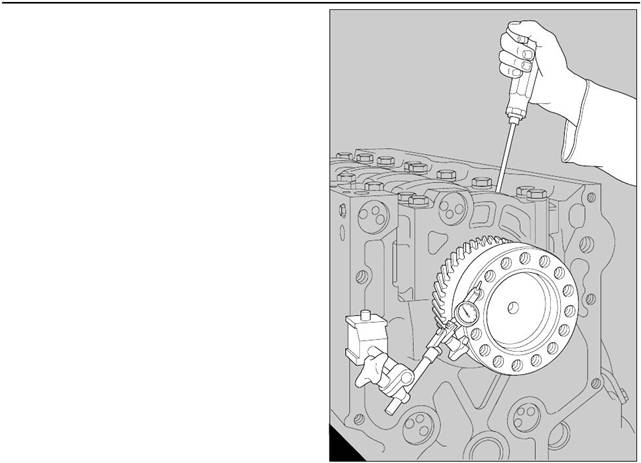

20 Fit the lubricating oil pump, operation 19-7.

21 For early engines, fit the sump adaptor, operation

19-3.

22 Fit the lubricating oil sump, operation 19-1 or, for

new engines, operation 19-5.

23 Fit the timing case and the timing gears, operation

15-5.

24 Fit the flywheel and the flywheel housing,

operation 22-4.

25 Fit the fan adaptor, operation 21-10.

26 Remove the engine from the build stand,

operation 16-1.

14

Perkins Engines Company Limited

87

This document has been printed from SPI². Not for Resale

14

14

To dismantle and to assemble

Special tools:

Lift adaptor, crankshaft VP 666

Remover/replacer, 27610005

14-5

To dismantle

1 Press down each plug (A1) of the reservoirs and

release the circlips. Fit the remover/replacer,

27610005 (A2), on the s pigot of the plug and withdraw

the plug. Early engines are fitted with a different type

of plug which has a threaded hole, for these engines

A

01

use remove/replacer, 21825 859, together with the

slide hammer, 21825 849. Clean all the components

with a degreasing solution.

To assemble

1 Fit new ’O’ ring seals to the blanking plugs of the

reservoirs. In sequence, apply a small amount of

’Stantyte’ lubricant or ’Morris’s liner lubricant’ around

the complete circumference of each housing in the

crankshaft. Press fully each plug into its housing and

fit the circ lip into its recess in the housing. Use the

relevant remover/replacer to pull backward the plug

4 Check for damage on the front and rear faces at the

ends of the crankshaft. Als o check for small marks on

the circumferences which are the location faces for

the flywheel and the pulley .

5 If the crankshaft is usable, small marks can be

removed from the journals, the crank pins, the thrust

faces and the locations on the ends by the use of a

very fine grade of oil stone.

Main bearings and thrust washers

against the circlip.

To clean and inspect

14-6

To inspect

14-7

To clean

1 Wash thoroughly the oil holes and reservoirs of the

crankshaft with kerosene and dry with compressed

air. Ensure that all surfaces of the crankshaft are

cleaned thoroughly.

To inspect

1 Hold the shaft in suitable wooden blocks under

main journals nos. 1 and 7. Check for crac ks in the

crankshaft, by the electro-magnetic method if

possible.

2 Check for damage and small marks on the main

journals, crank pins and thrust faces; check for ovality

the journals and crank pins. Refer to Perkins Engines

Company Limited, Shrewsbury, for the instructions

S.R.S. 121 Issue 2 for the repair of worn or damaged

journals and crank pins .

3 Hold the crankshaft in ’V’ blocks under the main

journals nos. 1 and 7 and check the amount of

deflection at the central main journal. The permissible

amount of the deflection, which is given on page 89,

must be gradual along the length of the crankshaft.

1 Remove the c rankshaft, operation 14-4.

2 Check for wear, cracks and contamination in the

surfaces of the bearings. Renew bearings as a set if

it is possible that a bearing will not complete a further

full period of service.

3 Check the thickness of the thrust washers.

Nominal dimensions for new thrust washers are:

2,93 to 3,0 mm (0.116 to 0.118 inch)

New thrust washers must be fitted if there is wear on

the thrust fac es and also if the crankshaft has

excessive end-float.

88

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale