產(chǎn)品中心

美國強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國道依茨 韓國大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

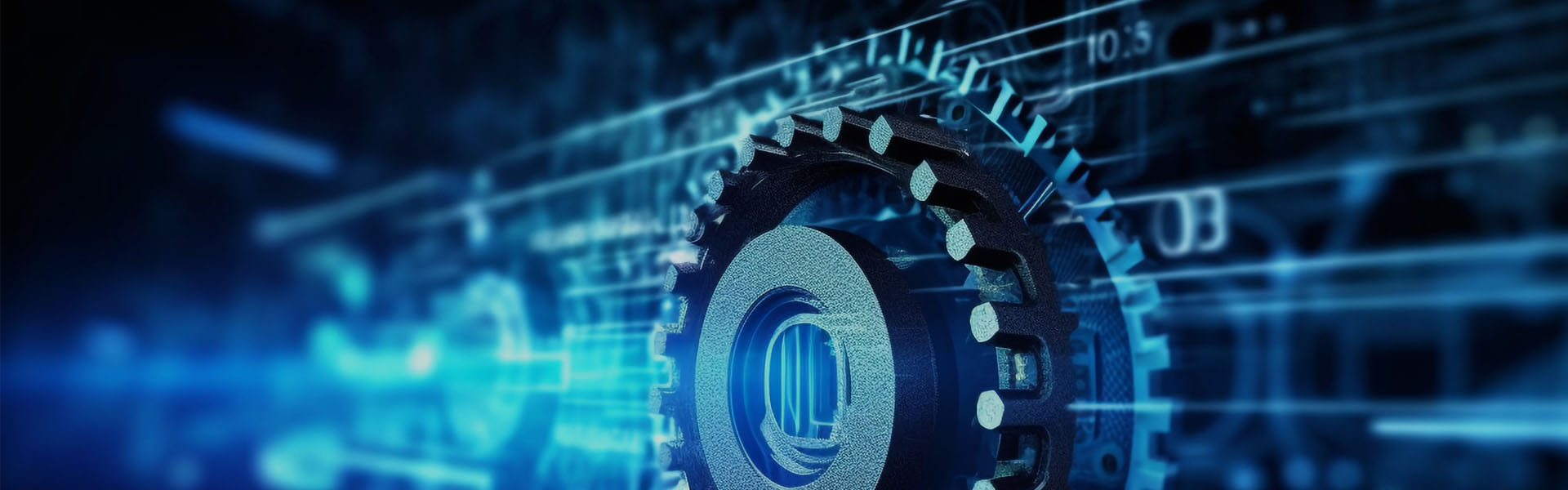

Perkins3012柴油發(fā)動(dòng)機(jī)威爾遜P850E柴油發(fā)電機(jī)配件曲軸瓦

詳細(xì)描述

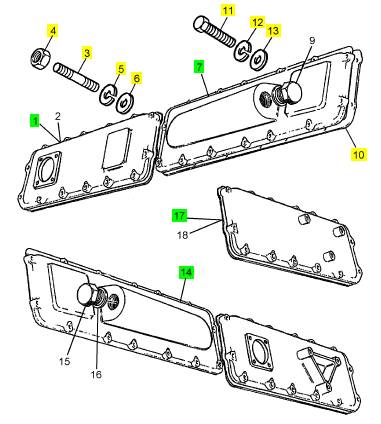

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

1 CV14877/1 Z 1 CV14877/1 Z 曲橋箱

11 KRP3106/010 1 KRP3106/010 曲軸瓦裝備 -U/S

11 KRP3106/020 1 KRP3106/020 曲軸瓦裝備 -U/S

11 KRP3106/030 1 KRP3106/030 曲軸瓦裝備 -U/S

11 KRP3106/040 1 KRP3106/040 曲軸瓦裝備 -U/S

11 KRP3106 1 KRP3106 曲軸瓦裝備

12 KRP3203/013 1 KRP3203/013 插入墊圈裝備 -O/S

12 KRP3203 1 KRP3203 止推片裝備

14 CV275 2 CV275 栓塞

24 CV9116 6 CV19408 噴射

26 ST44441 12 2314 C045 固定螺釘

27 ST43160 12 2134 A008 墊圈

31 CV1418 1 CV1418 板

32 CV20207 1 CV20207 切片密封墊的板

33 CV1420 1 CV1420 板

34 CV20208 1 CV68115 密封墊

35 ST44437 22 2314 C043 固定螺釘

36 ST20606 22 ST20606 墊圈

37 ST20133 1 ST20133I 栓塞

38 ST49891 1 ST49891 墊圈

39 ST45779 8 ST45779 合釘

40 ST20704 5 ST20704 栓塞

41 OE7669 4 OE7669 密封O型圈

42 CV13080 4 CV13080 栓塞

43 ST43324 4 ST43324 栓塞

44 ST20134 1 ST20134 栓塞

45 ST49206 1 ST49206 墊圈

46 CV1470 4 CV1470 線橋

47 CV7789 48 CV7789 圖釘

48 CV7790 32 CV7790 圖釘

49 CV7788 80 CV7788 螺帽

50 OE46176 80 OE46176I 墊圈

51 CV2910 1 CV2910 栓塞

52 CV20002 2 CV20002 固定螺釘

53 ST43333 1 ST43333 栓塞

54 ST43330 1 ST43330 栓塞

55 OE1647 1 OE1647 蓋

56 CV20236 1 CV20236I 密封墊

57 ST43556 2 ST43556 螺拴

58 2134 A010 2 2134 A010 墊圈

59 ST20103 1 ST46078I 栓塞

60 ST49853 1 ST49853 墊圈

61 ST20104 1 ST20104 栓塞

62 ST49891 1 ST49891 墊圈

63 ST20105 1 ST20105 栓塞

64 ST20107 1 ST20107 栓塞

65 ST49209 1 ST49209 墊圈

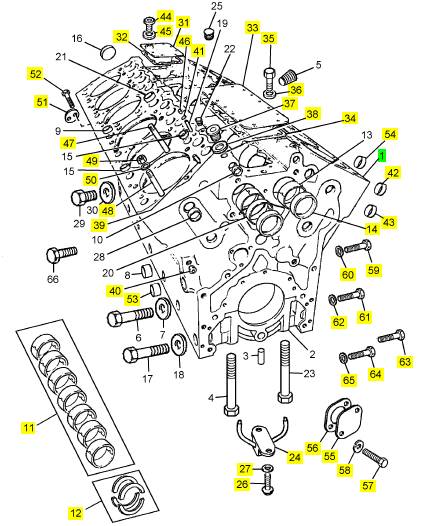

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

2 7 帽

3 CV270 1 CV270 合釘

4 CV278 8 CV24546 固定螺釘

5 ST20707 1 ST20707 栓塞

6 ST43706 8 ST43706 螺拴

7 ST43060 8 2131 A016 墊圈

8 ST43330 12 ST43330 栓塞

9 ST43326 10 ST43326 栓塞

10 ST33606 4 ST33606 栓塞

13 CV274 17 CV274 凸輪軸襯套

15 ST43322 20 ST43322 栓塞

16 ST43326 1 ST43326 栓塞

17 ST43657 6 ST43657 螺拴

18 CV9171 6 CV9171 墊圈

20 CV11572 1 CV11572 凸輪軸襯套

21 ST43328 2 ST43328 栓塞

22 ST20701 29 ST20701 栓塞

23 CV1271 12 固定螺釘

25 ST20702 2 ST20702 栓塞

28 ST43324 8 ST43324 栓塞

29 ST46076 1 ST46076I 栓塞

30 ST49851 1 ST49851 墊圈

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

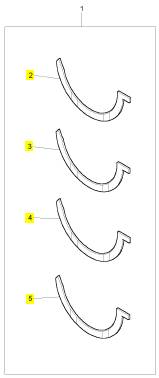

2 1 止推片

3 1 止推片

4 1 止推片

5 1 止推片

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

ST20139 2 ST20139 栓塞

ST49860 2 ST49860 墊圈

1 CV5519 1 室

3 CV2124 8 CV2124 圖釘

4 ST44605 8 2318 A208 公制的螺帽

5 ST43160 8 2134 A008 墊圈

6 ST43056 8 2131 A008 墊圈

7 CV7210/1 1 CV7210/1 冷卻器回廊裝備

7 CV7210/1 1 CV7210/1 冷卻器回廊裝備

7 CV7210 1 CV7210/1 冷卻器回廊

10 CV20232 4 CV72181 密封墊

11 ST43502 48 ST43502 螺拴

12 ST43160 48 2134 A008 墊圈

13 ST43056 48 2131 A008 墊圈

14 CV7211/1 1 CV7211/1 冷卻器回廊裝備

14 CV7211/1 1 CV7211/1 冷卻器回廊裝備

14 CV7211 1 CV7211/1 冷卻器回廊

17 CV5595 1 CV5595 室

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

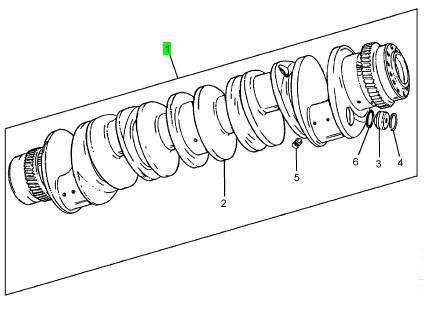

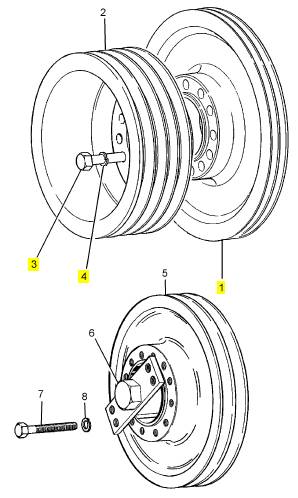

1 CV13835 1 CV24559 曲軸裝備

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

2 1 曲軸

3 CV13458 6 CV13458 栓塞

4 CV1209 6 CV1209 扣環(huán)

5 CV13830 3 CV13830 栓塞

6 ST10609 6 ST10609 密封O型圈

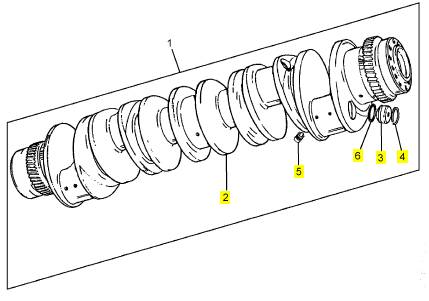

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

1 CV7926 1 曲軸皮帶輪

3 CV12174 12 CV12174 螺拴

4 2134 A012 12 2134 A012 墊圈

All rods which have the same letter have weights

which vary by less than 0,10 kg (0.22 lb) and rods

which have the same letter and number have weights

which vary by less than 0,025 kg (0.055 lb). If a

connecting rod is to be renewed, it important that the

new connecting rod is of the same group as the

original connecting rod.

The groups for the weights are as follows:

Y1 4,150 kg to 4,175 kg (9.149 to 9.204 lb)

Y2 4,175 kg to 4,200 kg (9.204 to 9.259 lb)

Y3 4,200 kg to 4,225 kg (9.259 to 9.315 lb)

Y4 4,225 kg to 4,250 kg (9.315 to 9.370 lb)

Z1 4.250 kg to 4,275 kg (9.370 to 9.425 lb)

Z2 4.275 kg to 4,300 kg (9.425 to 9.480 lb)

Z3 4.300 kg to 4,325 kg (9.480 to 9.535 lb)

Z4 4.325 kg to 4,350 kg (9.535 to 9.590 lb)

A1 4,350 kg to 4.375 kg (9.590 to 9.645 lb)

A2 4,375 kg to 4.400 kg (9.645 to 9.700 lb)

A3 4,400 kg to 4.425 kg (9.700 to 9.755 lb)

A4 4,425 kg to 4.450 kg (9.755 to 9.811 lb)

B1 4,450 kg to 4,475 kg (9.811 to 9.866 lb)

B2 4,475 kg to 4,500 kg (9.866 to 9.921 lb)

B3 4,500 kg to 4,525 kg (9.921 to 9.976 lb)

A

139

B4 4,525 kg to 4,550 kg (9.976 to 10.031 lb)

C1 4,550 kg to 4,575 kg (10.031 to 10.086 lb)

C2 4,575 kg to 4,600 kg (10.086 to 10.141 lb)

C3 4,600 kg to 4,625 kg (10.141 to 10.196 lb)

C4 4,625 kg to 4,650 kg (10.196 to 10.252 lb)

D1 4,650 kg to 4,675 kg (10.252 to 10.307 lb)

D2 4,675 kg to 4,700 kg (10.307 to 10.362 lb)

D3 4,700 kg to 4,725 kg (10.362 to 10.417 lb)

D4 4,725 kg to 4,750 kg (10.417 to 10.472 lb)

E1 4,750 kg to 4,775 kg (10.472 to 10.527 lb)

E2 4,775 kg to 4,800 kg (10.527 to 10.582 lb)

E3 4,800 kg to 4,825 kg (10.582 to 10.637 lb)

E4 4,825 kg to 4,850 kg (10.637 to 10.692)

The grades of the connecting rods fitted within a bank

of cylinders must all be the same; for example, ’A’

bank - all grade B1. A different grade of connecting

rod may be fitted in the other bank of cylinders, but

they must also be all the same within the bank; for

example, ’B’ bank - all C3.

The pistons are made of an aluminium alloy which

contains a high percentage of silicon. The tops of the

pistons have special toroidal combustion chambers to

give an efficient mix of fuel and air. Each of the early

pistons (A) has three compression rings and one oil

control ring. The new pistons have two compression

rings and one oil control ring. The top compression

rings of both types of pistons are wedge shaped and

their grooves are machined in hard metal inserts to

reduce the wear of the grooves.

Each 4-ring piston is tin plated on all the surfaces after

it has been manufactured, except the bore for the

gudgeon pin.

A 3-ring piston is tin plated below the top ring, except

the bore for the gudgeon pin, and the toroidal

combustion chamber is hard anodised. The axial

location of the fully floating gudgeon pin is controlled

by the circlips in the bore.

62

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

![]() Big end bearings

Big end bearings

13

To remove and to fit

Special tools:

Guide pin, 21825 843

13-1

To remove

1 Disconnect the batteries, stop the supply of the fuel

and drain the engine lubricating oil from the sump.

2 Remove the lubricating oil sump, operation 19-1 or,

for new engines, operation 19-5.

3 For early engines, remove the sump adaptor,

operation 19-3.

4 If necessary, release the bolts which retain the

lubricating oil pump and remove the lubricating oil

pump, operation 19-7.

5 Turn the crankshaft until the selected assembly of

the piston and connecting rod is at the bottom of its

stroke and remove the nuts of the big end bolts.

Remove the bearing cap and fit the guide pin, 21825

843, on to one of the big end bolts. Push carefully the

assembly up the cylinder bore just enough to allow

access to the upper half bearing.

Caution: There is a danger that the connecting rod

could fall against the cylinder liner and break it. The

use of the guide pin, 21825 843, ensures that this

damage cannot occur.

6 Remove the two half bearings from the connecting

rod and keep them together. Ensure that they can be

fitted in their original positions, if necessary.

To fit

1 Clean the connecting rod and the cap.

Caution: Renew the half bearings as a set of two if

there is doubt that they are acceptable for a complete

period of service. If it is not necessary to renew the

half bearings, ensure that they are fitted in their

original positions.

2 Clean the upper half bearing and lubricate the

bearing surface, the crank pin and the bolts and nuts

with clean engine lubricating oil. It is recommended

that new bolts and nuts are used. When the bolts are

fitted, press carefully each bolt into the connecting rod

until the bolt head is fully against the machined face

of the connec ting rod.

Perkins Engines Company Limited

63

This document has been printed from SPI². Not for Resale

13

13

3 Fit the off-centre upper half bearing to the

connecting rod. Ensure that the edges of the half

bearing are aligned with the edges of the parent bore

of the connecting rod. When it is fitted correctly, the

half bearing does not protrude ov er the chamfer on

the edge of the bore.

4 Use the guide pin, 21825 843, to pull the assembly

of the connecting rod and the piston down the bore

until the big end bearing is fitted on the crank pin.

Remove the guide pin from the connecting rod.

5 Clean the off-centre lower half bearing and fit it to

the cap. Ensure that the edges of the half bearing are

aligned with the edges of the parent bore of the

A

114

connecting rod. When it is fitted correctly, the half

bearing does not protrude over the chamfer on the

edge of the bore. Lubricate the bearing surface and

the crank pin. Ensure that the letters/numbers, which

are stamped on each bearing cap to give its

relationship, match the letters/numbers which are

stamped on the connecting rod, and fit the bearing

cap onto the bolts of the big end. Ensure that the

connecting rod does not fall from the crank pin.

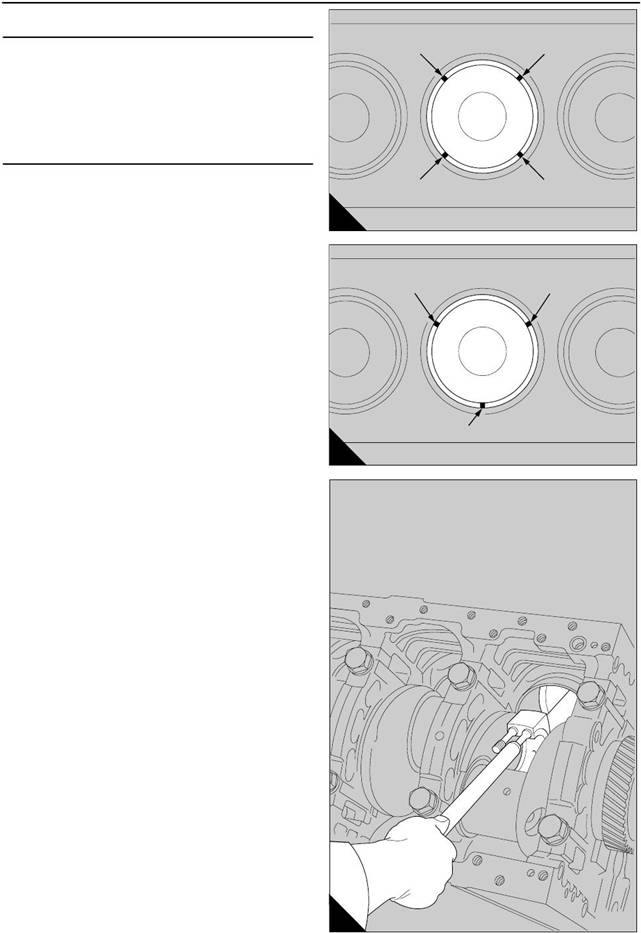

6 For engines fitted with connecting rod bolts which

have a ’D’ or square-shaped head, fit and tighten the

four nuts of the connecting rod, in the sequence

shown (B), to 20 Nm (15 lbf ft) and then to 45 Nm (33

lbf ft). The final operation is to tighten them to 70 Nm

(52 lbf ft). During the operation to tighten the bolts, if

the tension on the torque wrench reduces suddenly,

remove the bolt and fit a new bolt and nut.

For early engines, those with round headed

connecting rod bolts, proceed as follows: fit and

tighten the four nuts of the connecting rod, in the

sequence shown (B) to 20 Nm (14 lbf ft) and then to

40 Nm (28 lbf ft). The final operation is to tighten them

to 60 Nm (42 lbf ft). During the operation to tighten the

bolts, if the tension on the torque wrench reduc es

suddenly, remove the bolt and renew the bolt and its

nut.

Caution: Round headed connecting rod bolts are

NOT interchangeable with the later ty pes. Connecting

rods must be fitted with only the type of bolts which

were originally used.

7 Ensure that the crankshaft turns freely.

8 Fit the lubricating oil pump if relevant, operation 19-

7.

9 For early engines, fit the sump adaptor, operation

19-3.

10 Fit the lubricating oil sump, operation 19-1 or, for

new engines, operation 19-5.

11 Fill the sump to the correct level with engine

lubricating oil and connect the supply of the fuel.

12 Connect the batteries.

To inspect 13-2

1 Check the bearings and the crank pin for wear or

other damage.

64

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

![]() Piston and connecting rod assembly

Piston and connecting rod assembly

13

To remove and to fit

Special tools:

Guide pin, 21825 843

Retainers, 21825 844

13-3

To remove

1 Disconnect the batteries, stop the supply of the fuel

and drain the engine lubricating oil from the sump

2 Drain the cooling system.

3 Remove the relevant cylinder head, operation 12-9.

4 Remove the lubricating oil sump, operation 19-1 or,

for new engines, operation 19-5.

5 For early engines, remove the sump adaptor,

operation 19-3.

6 If necessary, release the bolts which retain the

lubricating oil pump and remove the lubricating oil

pump, operation 19-7.

7 Hold the relevant cylinder liner with the retainers,

21825 844, as necessary.

8 Turn the crankshaft until the selected assembly of

the piston and connecting rod is at the bottom of its

stroke and remove the nuts of the big end bolts.

Remove the bearing cap and fit the guide pin, 21825

843, on to one of the big end bolts. Push carefully the

assembly out through the top of the cylinder.

Caution: There is a danger that the connecting rod

could fall against the cylinder liner and break it. The

use of the guide pin, 21825 843, ensures that this

damage cannot occur.

Perkins Engines Company Limited

65

This document has been printed from SPI². Not for Resale

13

13

To fit

Special tools:

Height gauge, 21825 782

Guide pin, 21825 843

Retainer, 21825 844

Piston ring compressor, 21825 845

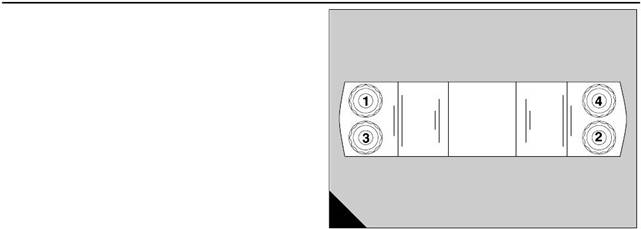

1 Turn the crankshaft until the relevant crank pin is at

BDC. Check that the upper half bearing of the big end

is in its position on the connecting rod. Set the gaps

of the piston rings in the positions shown (A) if the

pistons have four rings. If the pistons have three

rings, set the gaps as shown (B). Apply oil to the

crank pin, the upper half bearing and the piston, and

slide the piston ring compressor, 21825 845, over the

lower end of the piston with the tapered section

against the piston rings. Fit the guide pin, 21825 843,

onto one of the bolts of the big end bearing (C). It is

recommended that new bolts and nuts are used.

When the bolts are fitted, press carefully each bolt

into the connecting rod until the bolt head is fully

against the machined face of the connecting rod.

Caution: There is a danger that the connecting rod

could fall against the cylinder liner and break it. The

use of the guide pin, 21825 843, ensures that this

damage cannot occur.

Caution: If the old bolts and nuts have been used for

the connecting rod, they must first be inspected, for

signs of distortion of the threads, for stress, or for

indications of stretch, etc. Renew all bolts and nuts

that could be defective.

2 Fit carefully the assembly of the piston and the

connecting rod into its liner. Ensure that the cutout in

the lower wall of the piston is in the correct

relationship to the piston cooling jet assembly. Use

the guide pin to pull the assembly through the piston

ring compres sor and into the cylinder liner. Ensure

that the piston ring compressor is held, and does not

fall when it becomes free. Continue to pull the

assembly until the big end bearing is fitted on the

crank pin. If the piston and the connecting rod are

assembled correctly, the chamfer on the edge of the

bore in the big end is toward the crankshaft web.

Ensure that there is clearanc e between the piston and

the cooling jet.

Caution: During this operation, do not damage the

bearing surfaces of the crank pin and the half

bearings of the big end.

A

B

12

13

A

194

66

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

13

13

Caution: If a retainer, 21825 844, is removed to give

a clearance for the piston ring compressor, it must be

fitted again for each operation before the crankshaft is

turned.

3 Fit and tighten the four nuts of the connecting rod,

in the sequence shown (A) to 20 Nm (15 lbf ft) and

then to 40 Nm (30 lbf ft). The final operation is to

tighten them to 60 Nm (44 lbf ft). It is recommended

that the new bolts and nuts are used. Lubricate lightly

the threads and the contact faces before they are

fitted to the connecting rods.

Caution: The nuts of the connecting rod should be

tightened gradually and evenly. During this operation

avoid rapid or sudden movements of the torque

wrench.

4 Ensure that the crankshaft turns freely .

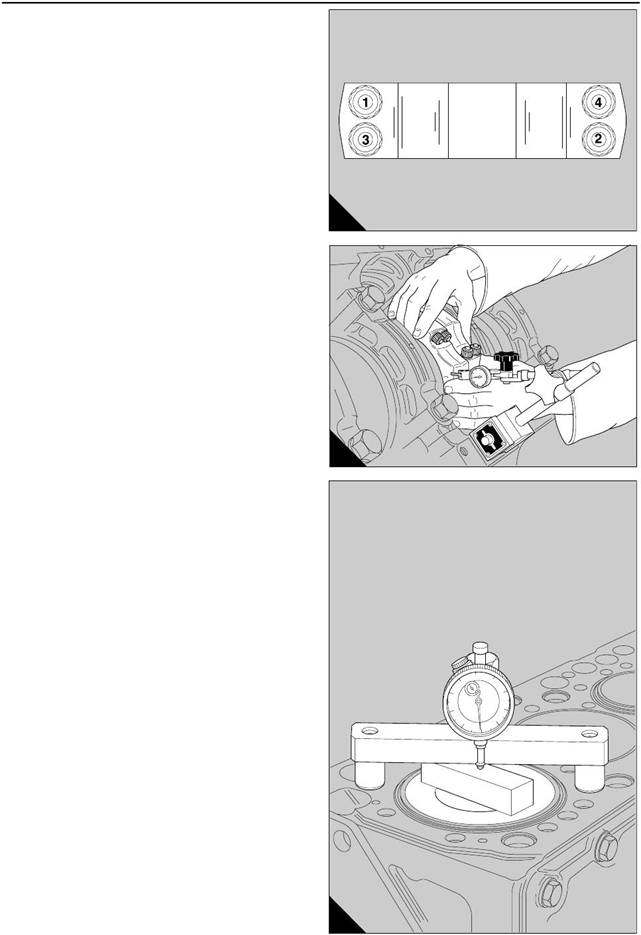

5 Check the end-float of the connecting rods with a

dial test indicator, as shown (B). The clearance for

each set of two connecting rods, between the big

ends and their relevant crankshaft webs, must be

0,20 mm to 0,40 mm (0.008 to 0.016 in).

6 Repeat the procedure for each assembly of a piston

and a connec ting rod.

Check the clearance between the top face of the

piston and the top face of the cylinder bank as follows:

7 Put the setting plate of the height gauge, 21825

782, on a clean s urface which is machined and put

the base of the tool over the setting plate. Align the

button of the dial gauge to make contact with the

centre of the plate. Set the dial gauge to zero and

tighten the locking screw.

8 Turn the crankshaft until one of the pistons is

almost at the top of its cylinder and move the setting

plate to the top face of the piston. Put the base of the

tool on the top face of the cylinder block, as shown

(C).

9 Continue to turn slowly the c rankshaft, to allow the

piston to pass TDC. As the piston passes TDC, make

a note of the reading on the dial gauge; the maximum

deflection of the pointer gives a minimum reading to

indicate the clearance between the top face of the

piston and the top face of the cylinder bank. The

permis sible clearance is from 0,31 to 0,38 mm (0.012

to 0.015 in). For engines manufactured from July

1998, fitted with piston number CV66887, the

permis sible clearance is from 0,31 to 0,75 mm (0.012

to 0.029 in).

A

B

114

197

B

198

Perkins Engines Company Limited

67

This document has been printed from SPI². Not for Resale

![]() 13

13

10 Check the clearance of each piston in the

cylinders of ’A’ bank, then turn the crankcase until the

cylinders of ’B’ bank are vertical. Repeat the

procedure to check the clearance of each piston in the

cylinders of ’B’ bank.

Caution: If not enough clearance is shown on the

dial gauge, the top face of the piston must be

machined to remove the minimum amount of material

which is necessary to give the correct clearance. This

will not be neces sary for engines manufactured after

July 1998 fitted with the piston XCV66887.

11 Fit the cylinder head, operation 12-9.

12 Fit the lubricating oil pump if relevant, operation

19-7.

13 For early engines, fit the sump adaptor, operation

19-3.

14 Fit the lubricating oil sump, operation 19-1 or, for

new engines, operation 19-5.

15 Fill the sump to the correct level with engine

lubricating oil and connect the supply of the fuel.

16 Fill the cooling system.

17 Connect the batteries.

To dismantle and to assemble 13-4

To dismantle

1 Remove the circlips which retain the gudgeon pin.

2 Push the gudgeon pin out by hand to release the

connecting rod. If the gudgeon pin is tight, heat the

piston in a tank of warm water. Keep together each

assembly.

To assemble

Before the connecting rod is assembled, check for

dirt and debris in the passage for the lubricating oil

and clean the pas sage with compressed air.

1 The gudgeon pin should be a push fit at 20°C

(68°F). If it is tight in its bore in the piston, heat the

piston in a tank of warm water. Remove the piston

from the water and use a clean and suitable rag to dry

the bore for the gudgeon pin. Fit one of the circlips

into its groove in the bore.

2 Give an applic ation of clean engine lubric ating oil to

the small end bush, the gudgeon pin and the bore for

the gudgeon pin.

68

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale