產(chǎn)品中心

美國(guó)強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國(guó)麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國(guó)珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢(xún)圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國(guó)道依茨 韓國(guó)大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷(xiāo)售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷(xiāo)售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

Perkins3012柴油發(fā)動(dòng)機(jī)威爾遜P850E柴油發(fā)電機(jī)配件活塞、活塞環(huán)

詳細(xì)描述

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

1 CV19976/1 12 CV19976/1 活塞裝備

5 CVK564 12 CVK564 活塞環(huán)裝備

10 CVK502 12 CVK502 活塞環(huán)裝備

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

2 1 活塞

3 1 橋頭銷(xiāo)

4 CV565 2 CV565 CIRCLIP

4 CV19330 2 CV19330 CIRCLIP

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

1 CV285 24 CV285 PUSHROD

2 CV70122 24 CV70122 挺桿

2 CV65451 24 CV70122 挺桿

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

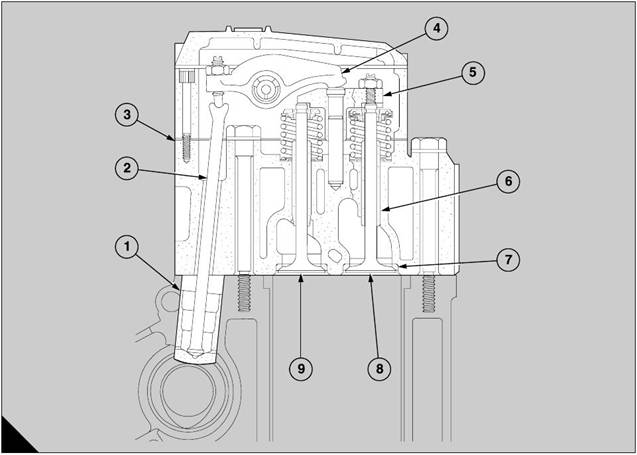

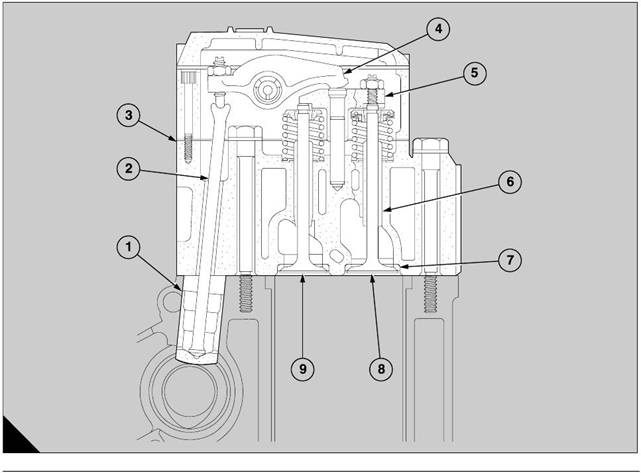

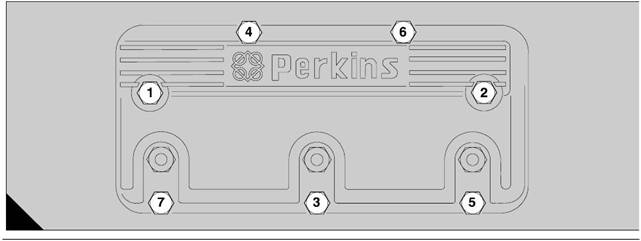

1 CV19148 4 CV19148 汽缸蓋蓋

2 CV20400 4 CV20400 密封 - 搖桿的砂箱蓋

3 2314 C045 16 2314 C045 固定螺釘

4 2134 A008 16 2134 A008 墊圈

5 2131 A008 16 2131 A008 墊圈

6 ST43502 8 ST43502 螺拴

7 2134 A008 8 2134 A008 墊圈

8 2131 A008 8 2131 A008 墊圈

9 ST43504 16 ST43504 螺拴

10 2134 A008 16 2134 A008 墊圈

11 2131 A008 16 2131 A008 墊圈

11

Lubricating oil pump

Bolts, casing

Nut, drive gear

Lubricating oil sump

Bolts

Insert, drain plug

Drain plug (sump with insert - early engines only)

Drain plug (single piece sump without insert)

Timing case

Bolts, timing case to crankcase

Bolts and nut (early engines)

Bolts and cap screws (later engines)

Bolts, timing case to sump

Bolts (early engines )

Bolts (later engines with steel joints)

Recommended nominal applied torques

Nm

23

120

55

325

115

47

95

135

55

75

lbf ft

17

89

41

240

85

35

70

100

40

55

Where instructions are not given for the correct torque to be applied to nuts and bolts, the figures which follow

should be used.

Bolt siz e Nm lbf ft

M5 6 4.5

M6 9.5 7

M8 23 17

M10 46 34

M12 80 59

M14 127 94‘

M16 198 146

M18 273 201

M20 387 285

M22 526 388

M24 669 493

28

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

12

12

Cylinder head assembly

General description

12

The four cylinder heads, which are all the same, are

made from high quality cast iron and are retained by

bolts or by studs on early engines. They are machined

on the top and bottom faces for the rocker box and the

cy linder head gaskets respectively. Joint faces are

machined on the inner and outer sides for the

induction and the exhaust manifolds. There are

passages for coolant in the cylinder head around the

valve guides and the pockets for the fuel injectors.

The valve guides (A6) are made from an alloy of high

quality nickel chromium and are a press fit in the

cy linder head. The valve seat inserts (A7) are cooled

and pressed into recesses which are machined in the

cy linder heads.

A

375

Perkins Engines Company Limited

29

This document has been printed from SPI². Not for Resale

12

12

The inlet valves (A9) are made from steel forgings.

The exhaust valves (A8) are made from solid

’Nimonic’ material. The valves are retained with

collets, springs and spring seat washers. Exhaust

valves are fitted with valve rotators instead of upper

spring seat washers. Each set of two valves is

actuated by a bridge piece (A5) which moves on a

guide. There is an adjustment screw and a lock nut

on the outer arm of each bridge piece. A nitrided

button is inserted in the top face of each bridge piece

and connects with its rocker lever (A4). Each rocker

lever is operated by the camshaft through a push rod

(A2) and a tappet (A1).

The rocker levers (A4) hav e adjustment sc rews and

lock nuts for the tappet clearances. For early

engines, they are ass embled on a rocker shaft in

each rocker box and are separated by the springs.

The rocker boxes are held in the correct positions on

the cylinder heads by spring dowels and are retained

with socket head cap screws and bolts, tightened to a

specific torque. The rocker box covers are made from

castings of aluminium and are retained by bolts. The

new rocker box covers of these engines are retained

with an extra bolt at each end.

Three fuel injec tors in each cylinder head are retained

by clamps and cap screws. The connec tions for the

fuel supply and the surplus fuel are sealed at the

rocker box covers and the walls of the rocker boxes

respectively, to prevent leakage of oil and the entry of

dirt.

Note: For the illustration (A), inlet and exhaust valves

are shown under the same bridge piece.

A

375

30

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

![]() New engines, from engine number 6A28293, do not

New engines, from engine number 6A28293, do not

have rocker boxes and each rocker shaft is mounted

on three pedestals whic h are bolted to the relevant

cy linder head. A rocker cover, formed in Vynalester,

encloses the rocker assembly. Bolt holes are sealed

with rubber washers and the interface with the

cy linder head is sealed with a special rubber sealing

ring.

For these engines, a new type of fuel injector is used.

These fuel injec tors are longer and have the

connections for the leak-off fuel above the rocker

covers.

A single cylinder head may be removed from the

engine and given an overhaul while the engine is still

connected to its relevant driven unit. In this situation,

ensure that the batteries are disconnected.

Pedestal rocker cover

12

1 Ensure that the seal is fitted correctly into the

groove around the pedestal rocker cover, put the

pedestal rocker cover on the cylinder head and fas ten

it to two of the pedestals by the two short bolts with

sealing washers. Do not tighten the bolts.

2 Fit the five long bolts, with sealing washers, through

the pedestal rocker cover into the cylinder head.

Tighten lightly all of the bolts.

3 Tighten evenly all the bolts in the sequence shown

(A) to a torque of 11 Nm (8 lbf ft).

4 Fit all other components which were removed, in

reverse sequence to their removal.

To remove and to fit

To remove

1 Disconnect the batteries.

12-1

2 Release the banjo connection bolts from the fuel

injectors and remove the relevant high pressure pipes

for the fuel supply from the fuel injection pump to the

fuel injectors.

3 Remove the two s hort and five long special bolts

which retain the pedestal rocker cover and then

remove carefully the pedestal rocker cover.

To fit

New sealing washers should be fitted to the special

bolts and a new seal fitted to the pedestal rocker

cover.

A

70

Perkins Engines Company Limited

31

This document has been printed from SPI². Not for Resale

![]() 12

12

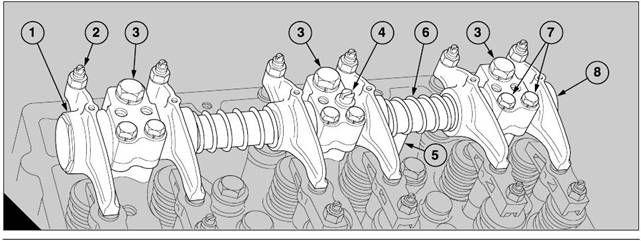

Pedestal rocker assembly

To remove and to fit

To remove

12-2

3 Fit a new ’O’ ring seal to each end of the lubricating

oil tube (A5) and lubricate the seals with engine

lubricating oil.

4 Turn the coils of the relevant spring (A6) to ensure

that there is clearance around the oil hole in the

rocker shaft and insert one end of the lubricating oil

tube into the hole. Ensure that the ’O’ ring seal is fitted

1 Remove the pedestal rocker cover, operation 12-1.

2 Loosen fully the adjustable screws of the roc ker

levers. Loosen the three bolts, each of which retains

one of the three pedestals, and lift v ertically away the

complete rocker assembly while holding the

lubricating oil tube which supplies the rocker shaft.

3 Remov e the lubricating oil tube from the rocker

shaft and ensure that the ’O’ ring seal at each end of

the tube is removed and discarded carefully.

4 Remov e the bridge pieces and the push rods, if

relevant.

5 If relevant to the job, remove the fuel injectors,

operation 20-7.

To fit

Note: After the pedestal rocker assembly has been

fitted, it is not possible to remove the bridge pieces

from either end of the cylinder head to tighten the

adjustment to the correct torque. If relevant to the job,

therefore, the bridge pieces must be set as instructed

in paragraphs 3 and 5 of operation 12-8 before this

operation is started.

1 If relevant, insert the extreme left hand push rod

through its opening in the cylinder head. If relevant,

give a full application of oil to the bridge pieces and

their guides and fit the bridge pieces onto their guides.

The other push rods may be fitted after the rocker

assembly is ins talled.

2 Ensure that the adjustment screws (A2) of the

rocker levers and the bridge pieces are loosened fully.

correctly and is not damaged. Hold the lubricating oil

tube in its position.

5 Lower the rocker assembly onto its cylinder head

and fit carefully the lubricating oil tube into its hole in

the cylinder head. Ensure that the ’O’ ring seal is fitted

correctly and is not damaged

6 Fit and tighten lightly the three bolts (A3) which

retain the pedes tals. If not already fitted, fit a spring

washer to the screw (A4) and fit the screw to the

tapped hole at the right of the central pedestal. Do not

tighten the screw. This screw controls the position of

the rocker shaft.

7 Check the end-float of each outer rocker lever (A1

and A8) with feeler gauges. Loosen the bolt which

retains each outer pedestal as necessary and adjust

its position to obtain the correct minimum clearance

of 0,12 mm (0.005 in). Tighten again the bolt and also

tighten the two s maller bolts (A7) which retain the

rocker shaft. It may be necessary to adjust also the

position of the central pedestal to obtain the correct

clearance at each end of the rocker shaft.

8 When the end-float at each end is correct, tighten

the three bolts to a torque of 80 Nm (59 lbf ft). Check

again the end float and tighten the two smaller bolts

on each pedestal to a torque of 23 Nm (17 lbf ft).

9 Tighten fully the sc rew (A4) in the central pedestal

which controls the position of the roc ker shaft.

A

207

32

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

![]() 10 Turn the remainder of the bridge pieces 90°, lower

10 Turn the remainder of the bridge pieces 90°, lower

them between the valve assemblies and tilt each

To assemble

12

rocker lever to insert the push rods through the

openings in the cylinder head. Fit the adjustment

sc rew of each rocker lever into the socket of its push

rod and return the bridge piece to its original position

to retain the push rod.

11 Turn c lockwise the adjustment screws until they

are nearly at their normal position.

12 Adjust the tappet clearances, paragraphs 5 to 20

of operation 12-8.

13 If relevant to the job, fit the fuel injectors, operation

12-7.

14 Fit the pedestal rocker cover, operation 12-1.

To dismantle and to assemble 12-3

To dismantle

Before the assembly is dismantled, identify each

component with a temporary mark. Make a note of

the sequence of the assembly of the components to

ensure that they can be assembled again in the

same sequence and with the hole for the lubricating

oil tube in the correct position.

1 Remove the screw in the central pedestal which

controls the position of the rocker shaft.

2 Remove the setscrews from each end of the rocker

shaft.

Caution: During this operation, prevent damage to

the hexagon flats of the setscrews because the end-

float of the rocker levers next to them may be

affected. The hex agons are 36,00/35,75 mm A/F.

3 Loosen the two small screws which retain the

rocker shaft in each pedestal and slide off each

pedestal, each rocker lever and each spring as it

becomes free.

4 To inspect and to correct the components, refer to

operation 12-7.

Before the setscrews are fitted to the ends of the

rocker shaft, ensure that all deposits of old locking

agent have been remov ed and that the internal/

external threads have been degreased.

1 Apply lightly 'Loctite 542' to the threads of one

setscrew and fit the setscrew to one end of the rocker

shaft.

2 Refer to the notes already made and assemble the

components onto the rocker shaft in the correct

sequence with the hole for the lubricating oil tube in

the correct position. Apply lightly 'Loctite 542' to the

threads of the second setscrew and fit the setscrew to

the other end of the rocker shaft.

3 Hold the assembly by the hexagon of one setscrew

in a vice with soft covers and tighten the other

setscrew to a torque of 24 Nm (17.7 lbf ft) to ensure

that both setsc rews are tightened equally.

Caution: During this operation, prevent damage to

the hexagon flats of the sets crews bec ause the end-

float of the rocker levers next to them may be

affected. The hexagons are 36,00/35,75 mm A/F.

4 To move the components along the rocker shaft,

compress the springs and apply clean engine

lubricating oil to the contact faces. Turn the rocker

shaft until the direction of the oil hole in the rock er

shaft is downward (toward the cylinder head).

5 Fit a spring washer to the screw which has a

screwdriver slot and fit the screw fully into the tapped

hole at the right of the central pedestal. This screw

controls the position of the rocker shaft.

Perkins Engines Company Limited

33

This document has been printed from SPI². Not for Resale

![]() 12

12

Rocker box cover

To remove and to fit

To remove

1 Disconnect the batteries.

12-4

6 Check that the socket of each push rod and the

adjustment screw of its relevant rocker lever are

aligned correctly. Tighten, gradually and evenly,

each bolt to 46 Nm (34 lbf ft) and each cap sc rew to

35 Nm (26 lbf ft).

7 Adjust the tappet clearances, operation 12-8.

8 Fit the rocker box covers, operation 12-4.

2 Disconnect and remove the relevant high pressure

pipes for the fuel supply from the fuel injection pump

to the fuel injectors and then remove the rocker cover.

To fit

1 Fit all components which were removed, in reverse

sequence to their removal.

Rocker box

To remove and to fit

To remove

12-5

1 Remove the rocker box covers, operation 12-4.

2 If relevant, release the connections for the leak-off

fuel from the fuel injectors and remove them through

the wall of the rocker box.

3 Loosen fully the adjustable screws of the roc ker

levers. Loosen ev enly and gradually the bolts and the

cap screws which retain the rocker boxes.

4 When the pressure of the valve springs is released,

lift away each rocker box.

5 Remov e the bridge pieces and the push rods, if

relevant.

To fit

1 Make locally some s uitable guide studs and fit four

guide studs for each rocker box in their relevant

cylinder heads. Check that the two dowels which

provide the location for each rocker box are fitted into

the cylinder heads.

2 Ensure that the adjustment screws of the rocker

levers and the bridge pieces are loosened fully.

3 Insert the 6 push rods through the apertures of

each cylinder head. Give a full application of oil to the

push rods, the guides of the bridge pieces and the

bridge pieces, and fit the bridge pieces into their

guides.

4 Remov e all the oil from the joint face of eac h

cylinder head and fit carefully the new joints in their

correct positions.

5 Fit each roc ker box assembly onto its cylinder head

and fit the spherical foot of each rod in its tappet. Fit

the 8 bolts, with the plain washers and the spring

washers, followed by the 8 cap screws which retain

each rocker box.

34

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

To dismantle and to assemble

To dismantle and to assemble

12-6

To assemble

12

To dismantle

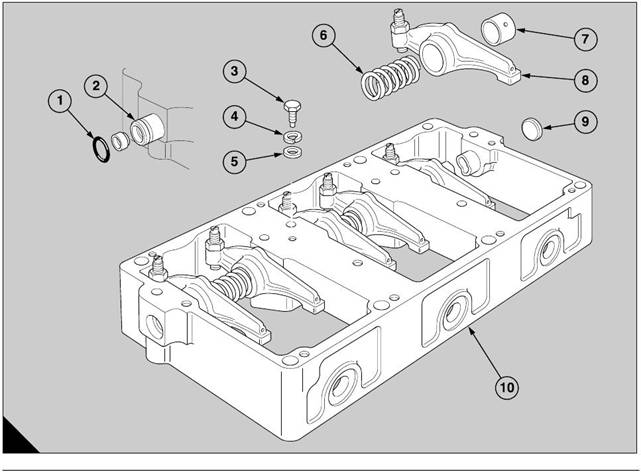

1 If relevant, remove the cup plug (A9) from the bore

for the shaft (A2) in the rocker box (A10).

2 Remove the bolt (A3) which retains the rocker shaft

and push the rocker shaft to the left, as seen from the

outer edge of the rocker box, until the ’O’ ring (A1) can

be removed from around the rocker shaft.

3 Continue to withdraw the rocker shaft and remove

each rocker lever (A8) and each spring (A6) as it

becomes free.

4 If a cup plug is not fitted in the bore of the rocker

box, push the rocker shaft enough in either direction

to remove one ’O’ ring and then push the rocker shaft

in the reverse direction to remove the second ’O’ ring.

5 Continue to withdraw the shaft and remove the

rocker levers and the springs as they become free.

1 If relevant, check that the bore for the cup plug in

the end of the rocker box is clean. Apply ’Loctite 542’

to a new cup plug and pres s it into the bore until it is

aligned with the wall of the rocker box.

2 Apply clean engine lubricating oil to the rocker shaft

and insert the end which has the opening into the bore

of the rocker box. Ensure that the oil hole in the

rocker shaft is facing directly downward (toward the

cylinder head).

3 Push the rocker shaft through the end, enough to fit

the first roc ker lever onto the rocker shaft. Continue to

push the rock er shaft through the rocker box and fit

the spring and the second rocker lever before the

rocker shaft enters the first pedestal. Fit the

remainder of the arms and springs in the correct

sequence.

4 Before the rocker shaft is pushed fully into its

correct position, fit the ’O’ ring in its groove around the

rocker shaft. Push further the rocker shaft until the

bolt hole in the rocker shaft is aligned with the

threaded hole in the pedestal. Fit the bolt that holds

the rocker shaft, with a plain washer (A5) and a spring

washer (A4), and tighten it sec urely.

A

339

Perkins Engines Company Limited

35

This document has been printed from SPI². Not for Resale