產(chǎn)品中心

美國強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國道依茨 韓國大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

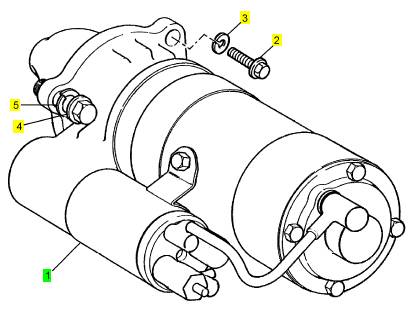

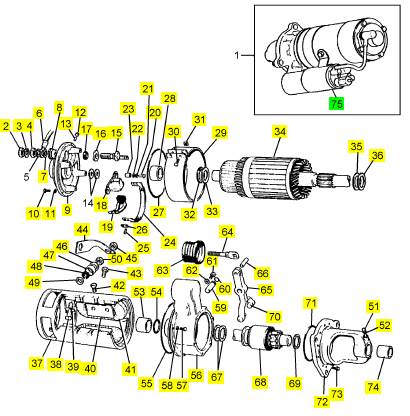

Perkins3012柴油發(fā)動(dòng)機(jī)威爾遜P850E柴油發(fā)電機(jī)配件啟動(dòng)馬達(dá)

詳細(xì)描述

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

1 CV5296 1 CV65430 啟動(dòng)馬達(dá)

(1) CV5296R 1 CV65430R 啟動(dòng)馬達(dá) -交換

2 ST44500 2 ST44500 固定螺釘

3 ST43164 2 ST43164 墊圈

4 ST44500 1 ST44500 固定螺釘

5 ST43164 1 ST43164 墊圈

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

2 OD17688 1 OD17688 鎖緊螺母

3 OD15391 1 OD15391 墊圈

4 OD15390 1 OD15390 螺帽

5 OD15400 1 OD15400 墊圈

6 CV3022 1 CV3022 鉛

7 OD19782 1 OD19782 墊圈

8 OD15396 2 OD15396 襯套

9 OD17266 1 OD17266 殼

10 OD15401 4 OD15401 固定螺釘

11 OD15402 4 OD15402 墊圈

12 OD15392 1 OD15392 栓塞

13 OD16762 1 OD16762 心

14 OD15404 12 OD15404 墊圈

15 OD17267 1 OD17267 連接

16 OD15400 1 OD15400 墊圈

17 OD15397 1 OD15397 CIRCLIP

18 OD17268 4 OD17268 夾持工具

19 OD15415 8 OD15415 刷

20 OD15408 4 OD15408 螺旋

21 OD15407 4 OD15407 墊圈

22 OD15406 4 OD15406 墊圈

23 OD15405 4 OD15405 襯套

24 CV4828 1 CV4828 連接

25 OD15412 8 OD15412 螺旋

26 OD15411 4 OD15411 板

27 OD15417 1 OD15417I 密封O型圈

28 OD15399 1 OD15399 襯套

29 OD17269 1 OD17269 帶

30 OD17270 2 OD17270 螺旋

31 OD15419 2 OD15419 螺帽

32 OD15410 1 OD15410 墊圈

33 OD15409 1 OD15409 墊圈

34 OD21480 1 OD21480 電樞

35 OD15423 1 OD15423 墊圈

36 OD15424 1 OD21474 墊圈

37 CV3024 1 CV3024 箱組合

38 CV3027 1 CV3027 螺旋

39 OD20701 1 OD20701 絕緣體

40 CV3026 4 CV3026 磁石的板

41 CV3025 1 CV3025 線圈

42 OD16748 8 OD16748 螺旋

43 OD15422 2 OD15422 螺旋

44 CV3021 1 CV3021 連接

45 OD17688 3 OD17688 鎖緊螺母

46 CV3030 1 CV3030 墊圈

47 OD20703 1 OD20703 絕緣體

48 OD15397 1 OD15397 CIRCLIP

49 OD20702 1 OD20702 絕緣體

50 OD15390 1 OD15390 螺帽

51 OD15392 1 OD15392 栓塞

52 OD16762 1 OD16762 心

53 OD19783 1 OD19783I 套筒

54 OD16755 1 OD16755 密封O型圈

55 OD15417 1 OD15417I 密封O型圈

56 OD17275 1 OD17275 殼

57 OD16754 5 OD16754 螺旋

58 OD15402 5 OD15402 墊圈

59 OD16753 1 桿

60 OD16752 1 OD16752 密封O型圈

61 OD16751 1 OD16751 螺旋

62 OD17276 1 OD17276 墊圈

63 OD16765 1 OD16765 長(zhǎng)靴

64 OD16756 1 OD16756 螺旋

65 CV3031 1 CV3031 桿

66 OD16747 1 OD16747I 軋輥銷

67 OD15424 2 OD21474 墊圈

68 OD16758 1 Y97/00032 駕駛

69 CV4838 1 CV4838 止推片

70 CV3032 2 CV3032 臂

71 OD16759 1 OD16759 密封O型圈

72 OD20704 1 OD20704 殼

73 OD16761 6 OD16761 螺旋

74 OD15399 1 OD15399 襯套

75 OD16764 1 OD16764 停機(jī)電磁線圈

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

77 OD17291 1 OD17291 磁石

78 OD17297 1 OD16764 柱塞

79 OD17282 1 OD17282 彈簧

80 OD18509 1 OD18509 橋

81 OD17252 3 OD17252 墊圈

83 OD17283 1 OD17283 彈簧

84 OD17284 1 OD17284 接觸

85 OD17285 1 OD17285 襯套

86 OD17287 1 OD17287 絕緣體

87 OD17185 1 OD17185 墊圈

88 OD17288 1 OD17288 螺帽

89 1 終點(diǎn)

90 1 終點(diǎn)

91 OD17286 1 OD17286 守衛(wèi)

92 2 終點(diǎn)

93 2 螺旋

94 OD17292 2 OD17292 絕緣體

95 OD17279 2 OD17279 圈

96 OD17252 1 OD17252 墊圈

98 OD17196 2 OD17196 螺帽

99 OD17245 1 OD17245 底座

100 OD17231 1 OD17231 螺旋

101 OD17298 1 OD17298 螺旋

102 OD17299 1 OD17299 螺旋

103 OE52575 4 OE52575 密封O型圈

104 OD17280 2 OD17280 墊圈

105 OD15391 2 OD15391 墊圈

106 OD15390 2 OD15390 螺帽

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

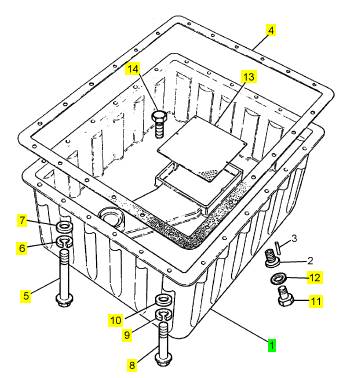

1 CV2852/1 1 CV12350 油底殼

4 CV20214 1 CV20214I 密封墊 -油底殼

5 ST43586 4 ST43586 螺拴

6 2134 A010 4 2134 A010 墊圈

7 2131 A010 4 2131 A010 墊圈

8 ST43561 20 ST43561 螺拴

9 2134 A010 20 2134 A010 墊圈

10 2131 A010 20 2131 A010 墊圈

11 CV985 1 CV985 栓塞

12 ST49206 1 ST49206 墊圈

13 CV2874 1 CV2874 過濾器

14 CV1275 7 CV1275 自己的出鐵螺旋

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

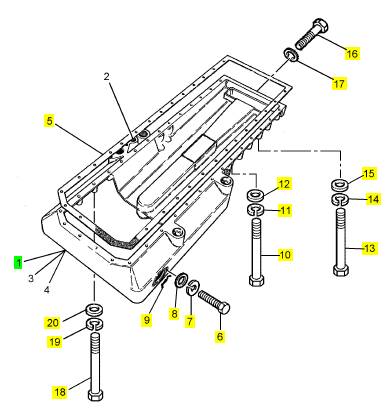

1 CV13339 1 CV13339 油底殼承接器

5 CV20213 1 CV20213 密封墊 -油底殼

6 ST43502 2 ST43502 螺拴

7 2134 A008 2 2134 A008 墊圈

8 2131 A008 2 2131 A008 墊圈

9 ST10619 1 ST10619 密封O型圈

10 ST46633 2 ST46633 CAPSCREW

11 2134 A010 2 2134 A010 墊圈

12 2131 A010 2 2131 A010 墊圈

13 ST43561 12 ST43561 螺拴

14 2134 A010 12 2134 A010 墊圈

15 2131 A010 12 2131 A010 墊圈

16 ST46633 5 ST46633 CAPSCREW

17 2134 A010 5 2134 A010 墊圈

18 ST43558 14 ST43558I 螺拴

19 2134 A010 14 2134 A010 墊圈

20 2131 A010 14 2131 A010 墊圈

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

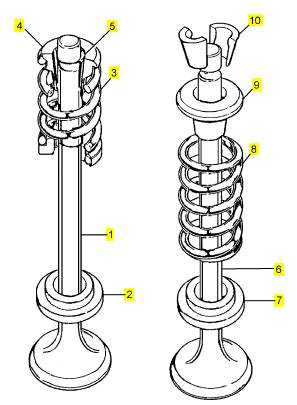

1 CV17435 24 CV21058 進(jìn)氣門

2 OE43638 24 OE43638 位子

3 CV11403 24 CV11403 閥彈簧

4 OE43262 24 OE43262 位子

5 OE42571 48 OE42571 閥筒夾

6 CV17434 24 排氣閥

7 OE43638 24 OE43638 位子

8 CV11403 24 CV11403 閥彈簧

9 CV18761 24 CV18761 回轉(zhuǎn)的人

10 OE42570 48 OE42570 閥筒夾

Perkins 3000 Series

WORKSHOP MANUAL

3012/CV12

|

|

The contents of this manual are applicable to both CV12 and 3000 Series - 3012 engines. |

Publication TSD 3420, Issue 3

© Perkins Group Limited 2000, all rights reserved.

Published in September 2000 by Technical Public ations.

Perkins Engines Company Limited, Lanc aster Road,

Shrewsbury SY1 3NX, England

1

This document has been printed from SPI². Not for Resale

2

This document has been printed from SPI². Not for Resale

Contents

10 General information

Introduction ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 13

Bank and cylinder bore identification . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 13

Engine identification . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 13

General safety precautions .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 14

Safety . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 15

Useful information ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 16

Approved lubricants and fluids ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 21

11 Specifications

Basic engine data . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 23

Recommended specific applied torques ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 26

Recommended nominal applied torques ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 28

12 Cyl inder head assembly

General description .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 29

Pedestal rocker cover

12-1 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 31

Perkins Engines Company Limited

3

This document has been printed from SPI². Not for Resale

Pedestal rocker assembly

12-2 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 32

12-3 To dismantle and to assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 33

Rocker box cover

12-4 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 34

Rocker box

12-5 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 34

12-6 To dismantle and to assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 35

12-7 To inspect and to correct ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 36

Tappet clearances

12-8 To check and to adjust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 38

Cylinder head assembly

12-9 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 40

12-10 To dis mantle and to assemble . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 44

12-11 To clean and to inspect the cylinder head ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 45

12-12 To correct a valve seat ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 46

12-13 To remove a v alve seat insert .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 47

12-14 To fit a valve seat insert ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 48

12-15 To ins pect the valve guides . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 49

12-16 To renew a valve guide ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 50

12-17 To ins pect the bridge pieces and guides . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 51

12-18 To renew a bridge piece guide ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 51

12-19 To recondition a fuel injector sleeve ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 52

12-20 To renew a fuel injector sleeve ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 53

Valves, valve springs and valve rotators

12-21 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 57

12-22 To ins pect and to correct . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 57

Push rods

12-23 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 58

12-24 To inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 58

Fits and clearances - Cylinder heads, rocker assemblies and valves . ... ... ... ... ... 59

Cylinder heads, rocker assemblies and valves (continued) . ... ... ... ... ... ... ... ... ... 60

4

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

13 Pistons and connecti ng rods

General description .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 61

Big end bearings

13-1 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 63

13-2 To ins pect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 64

Piston and connecting rod assembly

13-3 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 65

13-4 To dismantle and to assemble .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 68

Piston rings

13-5 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 70

Piston and rings

13-6 To ins pect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 71

Connect ing rod

13-7 To ins pect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 71

Fits and clearances - Pist ons and connecting rods

Pistons - 4 rings ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 72

Piston rings ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 72

Pistons - 3 rings ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 74

Piston rings ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 74

Connect ing rods ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 76

14 Crankshaft assembly

General description .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 77

Crankshaft pulley, damper and alternator pulley

14-1 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 78

Front oil seal

14-2 To renew ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 79

Rear oil seal

14-3 To renew ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 81

Perkins Engines Company Limited

5

This document has been printed from SPI². Not for Resale

Crankshaft

14-4 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 83

14-5 To dismantle and to assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 88

14-6 To clean and inspect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 88

Main bearings and thrust washers

14-7 To inspect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 88

Fits and clearances ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 89

15 Timing gears and timing case

General description ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 91

Timing gears and auxiliary drive shaft

15-1 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 92

15-2 To clean and to inspect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 98

Double idler gear

15-3 To dismantle and to assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 98

Auxiliary drive gear

15-4 To dismantle and to assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 98

Timing case

15-5 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 99

15-6 To clean and to inspect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 100

Fits and clearances ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 101

16 Crankcase and cylinder liners

General description ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 105

Crankcase

16-1 To fit to and to remove from a build stand . ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 107

16-2 To dismantle and to assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 110

16-3 To clean, to inspect and to correct . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 114

16-4 To test under pressure ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 115

Cylinder liner

16-5 To clean and inspect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 115

Fits and clearances ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 116

6

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

17 Camshafts and engine timing

General description .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 119

Camshafts

17-1 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 121

17-2 To clean and inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 125

Engine timing

17-3 To check the valve timing .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 126

17-4 To check/adjust the timing of the fuel injection pump ... ... ... ... ... ... ... ... ... ... ... 127

Fits and clearances ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 128

18 Induction and exhaust system

General description .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 129

Turbocharger

18-1 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 129

18-2 To dism antle and to assemble .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 131

18-3 To clean and to inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 134

Exhaust manifold

18-4 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 135

Induction manifold

18-5 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 135

Fits and clearances ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 136

19 Lubrication system

General description .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 137

Lubricating oil sump - early engines

19-1 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 139

19-2 To clean and inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 139

Sump adaptor - early engines

19-3 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 139

19-4 To clean and inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 140

Perkins Engines Company Limited

7

This document has been printed from SPI². Not for Resale

Single piece lubricating oil sump

19-5 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 140

19-6 To clean and inspect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 141

Lubricating oil pump

19-7 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 142

19-8 To dismantle and to assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 143

19-9 To clean and inspect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 144

Heat exchanger ( oil to coolant) - early engines

19-10 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 145

19-11 To dis mantle and to assemble . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 146

19-12 To clean and to inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 146

Mounting adaptor for the heat exchanger - early engines

19-13 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 147

Heat exchanger ( oil to coolant)

19-14 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 148

19-15 To dis mantle and to assemble . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 149

19-16 To clean and to inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 150

Relief valve

19-17 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 151

20 Fuel system

General description ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 153

Primary fuel filter

20-1 How to clean the primary fuel filter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 156

Fuel filter canisters

20-2 How to renew the canisters of the main fuel filter .. ... ... ... ... ... ... ... ... ... ... ... .. 156

Fuel filter head

20-3 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 157

Mechanical fuel lift pump

20-4 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 158

20-5 To dismantle and to assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 159

20-6 To tes t ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 160

8

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

Fuel injectors

20-7 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 161

20-8 To dism antle and to assemble .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 162

20-9 To clean and to inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 163

20-10 To set and to test ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 165

Fuel injection pump and governor

20-11 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 166

20-12 To dismantle and to assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 171

20-13 To inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 187

20-14 To calibrate the fuel injection pump ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 189

20-15 To test the fuel injection pump ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 190

Sizes of spacers (A) available for the tappets ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 192

Sizes of lower spring plates (A) available .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 193

Fuel system

20-16 How to eliminate air from the fuel system ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 194

21 Cooling system

General description .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 195

Radiator

21-1 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 197

21-2 To clean and to inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 197

Thermostats

21-3 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 198

21-4 To clean and to inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 198

Coolant pump

21-5 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 199

21-6 To dism antle and to assemble .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 200

21-7 To clean and to inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 202

Fan

21-8 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 203

Fan belts and tensioner pulley

21-9 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 204

Perkins Engines Company Limited

9

This document has been printed from SPI². Not for Resale

Fan adaptor

21-10 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 205

21-11 To dis mantle and to assemble . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 207

21-12 To clean and to inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 210

22 Flywheel and flywheel housing

General description ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 211

Flywheel

22-1 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 211

22-2 To inspect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 211

Starter ring

22-3 To renew ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 212

Flywheel housing

22-4 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 212

23 Electrical equipment

General description ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 215

Alternator

23-1 To remove and to fit ... .., . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 218

23-2 To dismantle and to assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 220

23-3 To clean . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 221

23-4 To inspect and to correct the rotor . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 221

23-5 To remove and to fit the rectifier ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 222

23-6 To tes t the main diodes with an ohmmeter or a test lamp . ... ... ... ... ... ... ... ... .. 222

23-7 To tes t the auxiliary diodes ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 223

23-8 To remove and to fit the D+ and F- wires .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 223

23-9 To check and to renew the car bon br ushes ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 223

23-10 To ins pect the stator and the housing .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 223

23-11 To ins pect the bearings ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 224

23-12 To renew the bearing at the slip ring end ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 224

23-13 To renew the bearing at the drive end . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 224

10

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

St arter motor

23-14 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 225

23-15 To dismantle and to assemble the solenoid switch . ... ... ... ... ... ... ... ... ... ... ... 226

23-16 To dismantle and to assemble the starter motor . ... ... ... ... ... ... ... ... ... ... ... ... 228

23-17 To clean .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 230

23-18 To inspect and to correct . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 230

23-19 To test . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 231

23-20 To fit the m ain starter cables ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 232

Electrical switches

23-21 To test . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 233

Engine st op solenoid (energised to run)

23-22 To adjust the linkage ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 234

Early 3012 engines ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 235

24 Auxi liary equipment

General description .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 237

25 Runni ng-in and test

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 239

Running-in and test

25-1 To run the engine .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 239

25-2 To chec k the consumption rate of the engine lubricating oil . ... ... ... ... ... ... ... ... 240

26 Special tools

List of special tools .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 241

Perkins Engines Company Limited

11

This document has been printed from SPI². Not for Resale

12

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

10

General information

Introduction

10

This workshop manual has been designed to provide

assistance in the service and the overhaul of Perkins

3012 (CV12) engines. Most of the general

information, which is included in the User’s Handbook

(Sections 1 to 9), has not been repeated in this

Workshop Manual and the two publications should be

used together.

Read the ’Safety precautions’ and remember them.

They are giv en for your protection and must be

applied at all times.

Danger is indicated in the text by two methods:

Warning! This indicates that there is a possible

danger to the person.

Caution: This indicates that there is a possible

danger to the engine.

Note: Is used where the information is important, but

there is not a danger.

Bank and cylinder bore identification

The left and right s ides of the engine are as seen from

the rear (flywheel) end. Where reference is made to

’A’ and ’B’ banks of cylinders: ’A’ bank is to the left and

’B’ bank to the right when viewed from the front end.

The cy linders are numbered from the front of the

crankcas e, A1 to A6 and B1 to B6.

To ensure that you use the correct information for

your specific engine type, refer to ’Engine

identification’ below.

Engine ident ification

The engine number is stamped on the data plate

which is fastened to the right side of the crankcase.

For early engines, a typical engine number is

6A27487U 59426V, which consists of these codes:

6A = Engine family

27487 = Engine number

U = Country of manufacture

59426 = Build line number

V = Year of manufacture

Engines produced after August 1994, have a new

engine number system. For these engines, a typical

number is: SGD 12 0012 U 1572 Y, which consists of

these codes:

SG = Engine applic ation

D = Engine type

12 = Number of engine cylinders

0012 = Engine specification number

U = The country of manufac ture

1572 = Build line number

Y = Year of manufacture

Units such as the fuel injection pump and

turbochargers have their own data plates.

If you need parts, service or information for your

engine, you must give the complete engine number to

your Perkins distributor.

Perkins Engines Company Limited

13

This document has been printed from SPI². Not for Resale

10

General safety precautions

These safety precautions are important.

Reference must also be made to the local regulations

in the country of operation.

l Only use these engines in the type of application

for which they have been designed.

l Do not change the specification of the engine.

l Do not smoke when you put fuel in the tank .

l Clean away fuel which has been spilt. Material

which has been contaminated by fuel must be

moved to a safe place.

l Do not put fuel in the tank while the engine runs

(unless it is absolutely necessary).

l Do not clean, add lubricating oil, or adjust the

engine while it runs (unless you have had the

correct training; even then extreme caution must

be used to prevent injury).

l Do not make adjustments that you do not

understand.

l Ensure that the engine does not run in a location

where it c an cause a concentration of toxic

emissions.

l Other persons must be kept at a safe distance

while the engine or equipment is in operation.

l Do not permit loose clothing or long hair near

moving parts.

l Keep away from moving parts during engine

operation. Warning! The fan cannot be seen

clearly while the engine runs.

l Do not operate the engine if a safety guard has

been removed.

l Do not remove the filler cap of the cooling system

while the engine is hot and while the coolant is

under pressure as dangerous hot coolant can be

discharged.

l Fuel and oil pipes MUST be inspected for cracks

or damage before they are fitted to the engine.

l Do not allow sparks or fire near the batteries

(especially when the batteries are on charge),

because the gases from the electrolyte are highly

flammable. The battery fluid is dangerous to the

skin and especially to the eyes.

l Disconnect the battery terminals before a repair is

made to the electrical system.

l Only one person must control the engine.

l Ensure that the engine is operated only from the

control panel or from the operator’s position.

l Be extremely careful if emergency repairs must be

made in adverse conditions.

l If your skin comes into contact with high pressure

fuel, obtain medical assistance immediately.

l

l

l

l

l

l

l

l

l

l

Read and use the instructions relevant to lift

equipment which are given on page 15.

Always use a safety cage to protect the operator

when a component is to be pressure tested in a

tank of water. Fit safety wires to secure the plugs

which seal the hose connections of a component

which is to be press ure tested.

Do not allow compressed air to contact your skin.

If compressed air enters your skin, obtain medical

help immediately.

Turbochargers operate at a high speed and at

high temperatures. Keep fingers, tools and other

items away from the inlet and outlet ports of the

turbocharger and prevent contact with hot

surfaces.

Diesel fuel and lubricating oil (especially used

lubricating oil) can damage the skin of certain

persons. Protect your hands with gloves or a

special solution to protect the skin.

Do not wear clothing which is contaminated by

lubricating oil. Do not put material which is

contaminated with oil into the pockets.

Discard used lubricating oil in a safe place to

prevent contamination.

Ensure that the control lever of the transmission

drive is in the ‘out-of-drive’ position before the

engine is started.

The combustible material of some components of

the engine (for example certain seals) can

become extremely dangerous if it is burned. Never

allow this burnt material to come into contact with

the skin or with the eyes.

Fit only genuine Perkins parts.

14

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

10

10

Safety

Engine lif t equipment

Use only the lift equipment which is designed for the

engine. The part number for the lift adaptor to use for

the 3012 engine is: 21825 822.

Use lift equipment or obtain assistance to lift heavy

engine components such as the cylinder block,

cy linder head, fly wheel housing, crankshaft and

flywheel.

Check the engine lift brackets for security before the

engine is lifted.

.

A

Asbestos joints

Some joints and gaskets contain compress ed

asbestos fibres in a rubber compound or in a metal

outer cover. The ’white’ asbestos (Chrysotile) which

is used is a safer type of asbestos and the danger of

damage to health is extremely small.

Contact with asbestos particles normally occurs at

joint edges or where a joint is damaged during

removal, or where a joint is removed by an abrasive

method.

To ensure that the risk is kept to a minimum, the

procedures given below must be followed when an

engine which has asbestos joints is dismantled or

assembled.

l Work in an area with good ventilation.

l Do NOT smoke.

l Use a hand scraper to remove the joints - do NOT

use a rotary wire brush.

l Ensure that the joint to be removed is wet with oil

or water to contain any loose particles.

l Spray all asbestos debris with water and place it in

a closed c ontainer which can be sealed for safe

disposal.

Environmental protection

There is legislation to protect the environment from

the incorrect disposal of used lubricating oil. To

ensure that the environment is protected, consult your

Local Authority who can give advice.

Viton seals

Some seals used in engines and in components fitted

to engines are made from Viton.

Viton is used by many manufacturers and is a s afe

material under normal c onditions of operation.

If Viton is burned, a product of this burnt material is an

acid which is extremely dangerous. Never allow this

burnt material to come into contact with the skin or

with the eyes.

If it is necessary to come into contact with

components which have been burnt, ensure that the

precautions which follow are used:

l Ensure that the components have cooled.

l Use Neoprene gloves and discard the gloves

safely after use.

l Wash the area with a calcium hydroxide solution

and then with clean water.

l Disposal of gloves and components which are

contaminated, must be in acc ordance with local

regulations.

If there is contamination of the skin or eyes, wash the

affected area with a continuous s upply of c lean water

or with a calcium hydroxide solution for 15-60

minutes. Obtain immediate medical attention.